HYPERBARIC FACILITIES MAINTENANCE MANUAL

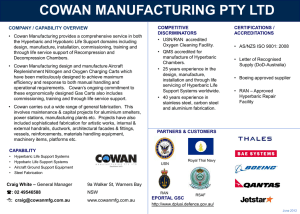

advertisement