IMPROVING ENERGY PERFORMANCE OF ARMY DINING FACILITIES Michael Deru, Ph.D. Donald Fisher

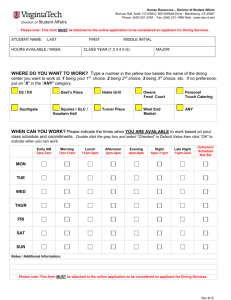

advertisement

IMPROVING ENERGY PERFORMANCE OF ARMY DINING FACILITIES Michael Deru, Ph.D. National Renewable Energy Lab Alexander Zhivov, Ph.D and Dale Herron Engineer Research and Development Center Donald Fisher Fisher Nickel, Inc Vernon Smith Architectural Energy Corporation Energy and Water Conservation Design Requirements for SRM Projects Table of Contents Introduction...............................................................................................................................3 Approach ...................................................................................................................................4 Existing Army Dining Facilities, Their Systems, Equipment and Issues .................................4 Army Dining Facilities Description............................................................................................5 Locations...................................................................................................................................6 Energy Modeling .......................................................................................................................6 Air Tightness and Infiltration ....................................................................................................8 Envelope....................................................................................................................................9 Lighting......................................................................................................................................9 HVAC ........................................................................................................................................10 Ventilation and Outside Air.....................................................................................................10 Results.....................................................................................................................................11 Energy Conservation Measures ............................................................................................ 12 Total Energy Savings with Recommended Technology Sets .................................................19 Summary and Discussion.......................................................................................................21 Acknowledgement...................................................................................................................21 References ............................................................................................................................. 22 List of Figures and Tables Figures Page 1 Sketch of a Proposed Army Dining Facility ..................................................................................................... 24 2 Proposed DFAC floor plan from the Army........................................................................................................ 24 3 Thermal zoning for the DFAC energy model.................................................................................................... 25 4 Rendering of the energy simulation model for the DFAC.............................................................................. 25 5 Daily process load electricity consumption profiles ...................................................................................... 26 6 Daily process load gas consumption profiles ................................................................................................. 26 7 Daily total process load consumption profiles of electricity and gas.......................................................... 27 8 Energy use by end use for the baseline building ............................................................................................ 27 9 Energy use by end use for regulated loads in the baseline building............................................................ 28 10 Annual energy savings for each ECM .............................................................................................................. 28 11 Various canopy hoods for cooking equipment (source, ASHRAE Standard 154)....................................... 29 12 Example best-design practices within exhaust system design and specifications................................... 29 2 Energy and Water Conservation Design Requirements for SRM Projects Tables Page 1 Building Zones and Internal Loads (IP units).................................................................................................... 5 2 Building Zones and Internal Loads (SI units).................................................................................................... 5 3 Climate Zones and Cities used for Simulations ............................................................................................... 6 4 Building Model Parameters ................................................................................................................................ 7 5 Process Loads....................................................................................................................................................... 9 6 Baseline Building Model Outside Air Requirements...................................................................................... 10 7 Baseline Exhaust Hood Air Flows..................................................................................................................... 11 8 Energy Budgets by Climate Zone ..................................................................................................................... 12 9 Energy Conservation Measures........................................................................................................................ 12 10 Envelope Conservation Measures.................................................................................................................... 14 11 Building Lighting Power .................................................................................................................................... 15 12 Efficient Building Model Outside Air Requirements ...................................................................................... 16 13 Energy Efficient Exhaust Hood Air Flows ........................................................................................................ 16 14 HVAC systems ..................................................................................................................................................... 17 15 Annual Energy Savings for Individual ECMs (kBtu/ft2) ................................................................................. 18 16 Annual Energy Savings for Individual ECMs 1000Btu/ft2 (MJ/m2) ............................................................. 18 17 Final Energy Efficient Design Solutions without Process Loads.................................................................. 19 18 Final Energy Efficient Design Solutions with Process Loads ....................................................................... 19 19 Summary of ECMs in Final Models (grey shading indicates not recommended or investigate on a case by case basis) ............................................................................................................................................ 20 Introduction Section 109 of the Energy Policy Act of 2005 (EPAct 2005) states that, for new federal facilities, “the buildings be designed to achieve energy consumption levels that are at least 30 percent below the levels established in the version of the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard or the International Energy Conservation Code, as appropriate” (U.S. Congress 2005). The energy efficient designs must be life cycle cost effective; however, the term “cost effective” is not defined in the law; it is left up to each federal agency to define. The U.S. Department of Energy (DOE) issued additional guidance in the Federal Register (NARA 2006), which states that savings calculations should not include the plug loads and implies that the savings shall be determined through energy cost savings. The U.S. Army decided it would use site energy for the HVAC, lighting, and hot water loads to determine the energy savings. 3 Energy and Water Conservation Design Requirements for SRM Projects The U.S. Army constructs buildings across the country and the Office of the Assistant Chief of Staff of the Installations Management and the U.S. Army Corps of Engineers (HQUSACE) worked to streamline the process of meeting the energy savings requirements. The U.S. Army Corps of Engineers (USACE) worked in collaboration with the National Renewable Energy Laboratory (NREL), and the ASHRAE Military Technology Group (MTG) to develop baseline and target energy budgets and design guides with a prescriptive path for achieving energy savings of 30% or more over the baseline. The project covers eight building types over all U.S. climate zones: basic training barracks, unaccompanied enlisted personal housing, battalion headquarters, tactical equipment maintenance facilities, dining facilities (DFAC), child development centers, Army reserve centers, and company operations. This paper focuses on DFAC; however, the process for developing all the design guides is similar. The concept for these design guides was adapted from the Advanced Energy Design Guides (AEDGs) from ASHRAE (2008). Each AEDG was developed for a specific building type and provides recommendation tables for each of the eight major climate zones and a “how-to” section on implementing the recommendations. The AEDGs do not provide baseline and target energy budgets, which are used by the Army in its requests for proposals. Approach A representative model of the DFAC building was developed based on the information provided by the USACE Norfolk District – the DFAC Center of Standardization. Baseline and target energy budgets were developed and energy savings using different sets of technologies were analyzed. Energy conservation technology candidates were selected based on previous energy design guide work (FSTC 2004a) and input from commercial kitchen consultants, who have experience with military kitchens. All energy simulations for the DFAC were carried out with EnergyPlus version 2.1 (DOE 2008). NREL is part of the EnergyPlus development team and has developed additional programs that work with EnergyPlus. These programs work together to create input files, manage the numerous simulations, provide optimization, and post-process the results. The optimization engine, called Opt-E-Plus, is used to help optimize building designs based on energy performance, energy cost performance, or life cycle cost performance. A baseline building energy model was created from the representative DFAC model meeting the minimum requirements of ASHRAE Standard 90.1-2004 following Appendix G (ASHRAE 2004a). We followed Appendix G with two exceptions, which were approved by DOE. For this project analysis we used site energy based on the Army decision, and developed baseline and target energy budgets without plug or process loads as our metric for savings following EPAct 2005 guidance from DOE. Finally, Standard 90.1-2004 does not contain requirements to building air leakage and infiltration levels. For the DFAC, we defined a baseline air leakage rate and an energy efficient leakage rate and included this factor in our energy efficiency analysis. Existing Army Dining Facilities, Their Systems, Equipment and Issues Existing Army dining facilities were not designed with energy and water efficiency as a primary objective. While minimizing construction costs have always been a goal within facility design, specifying lower-first-cost equipment that is inherently energy inefficient has been a reality with the design of Army dining facilities. Although the focus has changed within the context of the 2005 Energy Policy Act, it is not possible to economically transform existing facilities into “Energy Star” models of institutional food service. It is still practical, however, to implement such low-cost energy conservation measures as lowflow prerinse spray valves in the dishroom, or high-efficiency motors for evaporator fans in walk-in coolers as energy efficiency transformation is approached on a step-by-step basis. Since dining facilities are among the buildings on Army installations that use the most energy, comprehensive audits 4 Energy and Water Conservation Design Requirements for SRM Projects should be initiated in existing dining facilities to address the many available no-cost, low-cost, and investment grade retrofits of ventilation, lighting, and automation systems, and equipment replacement opportunities. It is imperative that energy efficient options (e.g., Energy Star-qualified for applicable equipment categories including fryers, steamers, holding cabinets, ice machines, reach-in refrigerators and freezers) be considered when existing equipment is changed out (EPA 2008). Where Energy Star categories do not exist, FEMP-recommended or California-rebate-qualified equipment should be considered (FEMP 2008, FSTC 2008b). Army Dining Facilities Description The Army has developed standard designs for their dining facilities ranging in size from 251 to 500, 501 to 800, 801 to 1300, and 2600 meals based on the number of meals served in a single meal time. Most of the building elements scale with the size of the building. However, the kitchen is nearly the same size across all models to fit a standard set of food preparation equipment. The basic design is a single story building with spaces for food preparation, serving, dining, dishwashing, take-out food area, employee break area, storage, and utilities. The design must facilitate feeding the maximum number of meals in an hour and a half. Much of the short-order cooking is accomplished in the serving area on broilers or griddles, range tops, and in ovens. Several ventilation hoods are required to service the cooking equipment. In addition to the cooking equipment, there is a walk-in cooler and a walk-in freezer and several reach-in refrigerators and other ancillary equipment typically found in commercial foodservice. Figure 1 shows a sketch of a proposed dining facility. A dining facility serving between 801 and 1300 meals was selected for our study – this is a medium sized building and the one most often constructed. The proposed floor plan from the Army shown in Figure 2 has an area of 25,609 ft2 (2,379 m2). The building is occupied 7 days a week from 3 a.m. to 8 p.m. Tables 16-1 and 16-2 list the zones and thermal loading. Table 1. Building Zones and Internal Loads (IP units). Area (ft2) Zone Volume (ft3) People Lights (W/ft2) Electric Equipment (W/ft2) Gas Equipment (W) Dining 7,981 95,772 500 0.9 Storage/Receiving 2,622 31,465 5 0.8 3.76 0.25 Dish wash 1,120 13,439 5 1.2 51.79 Kitchen 2,763 33,150 12 1.2 14.84 54,000 Servery 4,277 51,324 50 1.2 23.85 29,000 Entry/Circulation 3,290 39,478 35 1.3 0.25 Carryout 1,044 12,528 6 1.2 12.45 Office 1,444 17,328 6 1.1 0.75 Utility 1,053 12,637 0 1.5 0.25 Total 25,593 307,120 619 26,486 W 246,824 W 14,000 93,000 W Table 2. Building Zones and Internal Loads (SI units). Area (ft2) Zone Volume (ft3) People Lights (W/ft2) Electric Equipment (W/ft2) Gas Equipment (W) Dining 741 2,712 500 9.68 40.46 Storage/Receiving 244 891 5 8.61 2.69 Dishwashing 104 381 5 12.91 557.46 Kitchen 257 939 12 12.91 159.75 54,000 Servery 397 1,453 50 12.91 256.70 29,000 Entry/Circulation 306 1,118 35 13.99 2.69 Carryout 97 355 6 12.91 134.04 5 14,000 Energy and Water Conservation Design Requirements for SRM Projects Area (ft2) Zone Volume (ft3) People Lights (W/ft2) Electric Equipment (W/ft2) Office 134 491 6 11.84 8.07 Utility 98 358 0 16.14 2.69 Total 2,378 8,697 619 27,759 246,824 Gas Equipment (W) 93,000 W Locations Fifteen locations were selected to represent 15 climate zones in the United States based on TMY2 weather files. The locations were selected as representative cities for the climate zones by the Pacific Northwest National Laboratory (Briggs et al. 2003). We selected Colorado Springs for climate zone 5B instead of Boise, ID to more closely align with the installations at Fort Carson, CO. Table 3 lists the 15 climate zones and the cities used to represent the climate zones. Table 3. Climate Zones and Cities used for Simulations. Climate Zone City HDD Base 65ºF (18ºC) CDD Base 50ºF (10ºC) 1A Miami, FL 200 (111) 9474 (5263) 2A Houston, TX 1599 (888) 6876 (3820) 2B Phoenix, AZ 1350 (750) 8425 (4681) 3A Memphis, TN 3082 (1712) 5467 (3037) 3B El Paso, TX 2708 (1504) 5488 (3049) 3C San Francisco, CA 3016 (1676) 2883 (1602) 4A Baltimore, MD 4707 (2615) 3709 (2061) 4B Albuquerque, NM 4425 (2458) 3908 (2171) 4C Seattle, WA 4908 (2727) 1823 (1013) 5A Chicago, IL 6536 (3631) 2941 (1634) 5B Colorado Springs, CO 6415 (3564) 2312 (1284) 6A Burlington, VT 7771 (4317) 2228 (1238) 6B Helena, MT 7699 (4277) 1841 (1023) 7A Duluth, MN 9818 (5454) 1536 (853) 8A Fairbanks, AK 13940 (7744) 1040 (578) Energy Modeling The energy simulations were completed using EnergyPlus version 2.1 (DOE 2008). All simulations were completed with the NREL analysis platform based around Opt-E-Plus that manages EnergyPlus simulations. This section describes the modeling assumptions used in the baseline and energy efficient models. Figure 3 shows the thermal model of the DFAC used for this study, a one story, 25,593 ft2 (2,378 m2) building. Figure 4 shows the rendered view of the energy simulation model. The skylights in the servery and dining zones are used for daylighting in the energy efficient models. The skylights must be included in the baseline building as well according to Standard 90.1-2004 Appendix G modeling rules. The skylights and daylighting did not provide energy savings in Fairbanks and are not included in the energy models for this location. Table 4 lists the building model parameters. There were some issues with modeling this building in EnergyPlus, which introduced some errors and required some changes in the model inputs. There are several hours of unmet heating loads from a bug in EnergyPlus control algorithms that lead to temperatures dropping about 1ºF (0.6ºC) below the 6 Energy and Water Conservation Design Requirements for SRM Projects setpoint. This problem occurs in zones with high outside air and in cold climates. The result is a slightly lower heating energy than what it should be, which was assumed to be small and was ignored in this study. The bug is known to the EnergyPlus development team and may be fixed in a future release of EnergyPlus. Another issue was undersizing of cooling coils in hot climates. This was corrected by increasing the zone sizing factor for the kitchens in Houston, Phoenix, and El Paso. One final issue concerns the outside air for zones with exhaust fans and transfer air, which is discussed further in the section on ventilation. Table 4. Building Model Parameters. Building Component Baseline Building Model Efficient Building Model Area 25,593 ft2 (2,378 m2) Same as baseline Floors 1 Same as baseline Aspect ratio 4.4 Same as baseline Fenestration type Standard 90.1-2004 See Tables 16-10 and 16-11 Wall construction Steel frame Steel frame Wall insulation Standard 90.1-2004 steel frame See Tables 16-10 and 16-11 Roof construction Flat built up roof Flat built up roof Roof insulation Standard 90.1-2004 equal to the “insulation entirely above deck” See Tables 16-10 and 16-11 Roof albedo 0.3 Same as baseline Infiltration 0.4 cfm/ft2 @ 0.3 in w.g. (2.0 L/s·m2 @ 75 Pa) 0.25 cfm/ft2 at 0.3 in w.g. (1.25 L/s/m2 at 75 Pa) Temp setpoints 70ºF (21ºC) heating; 75ºF (24ºC) cooling – set back/up Same as baseline to 55ºF (13ºC) heating; 91ºF (33ºC) cooling Kitchen: 80ºF (27ºC) cooling - set up to 91ºF (33ºC) HVAC PSZ with DX-AC (3.05 COP) and gas furnace (0.8 Et); See Table 15 DHW Natural gas boiler (0.8 Et) Natural gas boiler (0.94 Et) Plug and Process Loads Several assumptions have to be made to include the plug and process loads in the energy models. The process loads for a commercial kitchen are large and have a significant impact on the HVAC and overall building energy use. The 2007 DOE Buildings Energy Data Book estimates that the cooking and refrigeration loads in a typical “Food Service” building is approximately 45% of the total energy use (DOE 2007). The process loads associated with food preparation, serving, and cleaning for this model were estimated by foodservice industry consultants. Kitchen appliances for both the baseline building and the energy efficient building were all selected to be either ENERGY STAR-qualified, FEMPrecommended, or qualified for California utilities Rebate Program (EPA 2008, FEMP 2008, FSTC 2008b). USACE Norfolk District provided with the layout of the kitchen, the equipment specification sheets, a 21-day menu, and the number of meals served per day. The cooking energy for each piece of equipment was estimated for each space based on the menus and aggregated schedules were created for each space including warm-up and idle times. Figures 16-5, 16-6, and 16-7 show (and Table 5 lists) the total electricity and gas process loads by zone. Service hot water (SHW) use in the food preparation and dish washing areas is considered a process load and is removed from the energy savings calculations. It was assumed that 95% of the building SHW use is for food preparation and washing (see Table 5). The remaining 5% is for hand washing in the restrooms and hand washing stations in the entry and is included in the energy savings calculations. 7 Energy and Water Conservation Design Requirements for SRM Projects Air Tightness and Infiltration Infiltration is a difficult parameter to obtain good data on. Every building has different air leakage and the infiltration varies with operation of the building and ambient conditions. There was a proposed addendum to Standard 90.1-2004, which includes an air tightness standard. This document proposes that one approach to meeting the standard would be to perform a pressurization test to show that the building leakage does not exceed 0.4 cfm/ft2 at 0.3 in w.g. (2 L/s/m2 at 75 Pa). This air tightness level provides a number that can be used for the energy simulations and was assumed to be the leakage rate for the baseline building models in this analysis. 8 Energy and Water Conservation Design Requirements for SRM Projects Table 5. Process Loads. Zone Dining Peak Elec. (kW) 30 Electric (kWh/day) Peak Gas 1000Btu (MJ) Gas 1000Btu/day (MJ/day) 1,989 (2,099) 165 Dishwashing 58 330 Kitchen 41 447 183 (193) Servery 99 901 47 (50) 394 (416) 3 44 57 (60) 620 (654) 188 47 (50) Bake shop Carryout Total 13 Service Hot Water gal/day (L/day) 2,075 422 (445) 3,425 (3,614) 5,740 (21,728) Based on input from building air tightness experts, the U.S. Army has proposed in their new construction regulations that the leakage rate must not exceed 0.25 cfm/ft2 at 0.3 in w.g. (1.25 L/s/m2 at 75 Pa), which was assumed for the energy efficient building models in this study. Several assumptions still have to be made to go from these leakage rates to the simple infiltration model in the building energy simulation. The infiltration at these leakage rates and pressures were calculated based on the above grade envelope area (exterior walls and roof) of the building then converted to a pressure of 0.02 in w.g. (5 Pa) assuming a flow coefficient of 0.65. It was assumed that the average pressure difference across the building envelope is 0.02 in w.g. (5 Pa). Tables 16-6 and 16-13 lists the infiltration values. Infiltration is often assumed to go to zero when buildings are pressurized. This assumption is usually made because there is a lack of evidence to know what really happens and lack of knowledge of how to model it in an energy simulation. We have assumed that the uncontrolled infiltration is reduced to 10% of the value calculated at 5 Pa when the building ventilation system is running. When the ventilation system is off (no outside air), the infiltration is modeled at the full leakage rate calculated at 5 Pa. Infiltration is modeled at constant air changes per hour. Wind pressure and temperature differentials across the building envelope drive the infiltration and these driving forces vary throughout the year; however, we are not modeling these variations in the simulation models. We are assuming that a constant air changes per hour (ACH) models the average effects over the year and in different locations. This is a gross assumption, but one that is necessary without moving to more complicated flow network simulations. Envelope The baseline building envelope features are modeled as steel frame wall construction, roof insulation entirely above deck, and door and fenestration types from ASHRAE Standard 90.1-2004. The door, window, and skylight sizes and distribution are exactly the same in all building models. Skylights are included at 4% of the roof area in the servery and dining zones for daylighting. Skylights are not included near the exterior walls in the dining zone because adequate daylight can be harvested from the exterior windows. Skylights are not included in the models for Fairbanks because the latitude and cold climate reduce their effectiveness in saving energy. Lighting Tables 16-18 and 16-2 list the interior lighting power densities (LPD) for the baseline and the energy efficient model for each space. 9 Energy and Water Conservation Design Requirements for SRM Projects HVAC The baseline HVAC system from Standard 90.1-2004 Appendix G is the system 3 package single zone air conditioning (PTAC) system for each zone. The systems were auto-sized by EnergyPlus for each simulation with a 1.2 sizing factor. The kitchen had over 300 hours of the cooling temperature setpoint not met in Houston, Phoenix, and El Paso. A sizing factor of 2.0 was used for the kitchen in these locations to ensure that the number of hours that the cooling setpoints were met did not exceed 300 as required by Standard 90.1-2004 Appendix G. Ventilation and Outside Air The outside air requirements for each zone are determined by meeting the highest of the Standard 62.1-2004 (ASHRAE 2004c) outside air requirements and the make-up air requirements for the food preparation exhaust hoods. Table 6 lists the building infiltration, ventilation, and outside air requirements for the baseline building. The maximum outside air for the servery in the last column is slightly greater than the maximum exhaust hood flow minus the transfer air because the hourly operation of the individual hood flows and the transfer air cause the peak air flows to occur at different times. Some of the make-up air for the servery exhaust hoods comes from the dining and entry/circulation areas. The transfer air from the entry/circulation is very small and was not included in the energy simulations. A small amount of make-up air for the kitchen comes from the adjacent storage area; however, this transfer air is small and was not included in the simulations. The transfer air is the same for all models; therefore, no credit is taken in the energy efficient models for transfer air. Table 6. Baseline Building Model Outside Air Requirements. Zone Infiltration cfm (L/s) 62.1-2004 Ventilation cfm (L/s) Dining 768 (362) 5,187 (2,448) Storage/Receiving 248 (117) 315 (149) Transfer Air cfm (L/s) Exhaust Hood cfm (L/s) -4,496 (2,122) Maximum Outside Air cfm (L/s) 5,187 (2,448) 315 (149) Dishwashing 77 (36) 784 (370) 750 (354) 750 (354) Kitchen 190 (90) 1,934 (913) 13,250 (6,253) 13,250 (6,253) Servery 294 (139) 1,145 (540) Entry/Circulation 294 (139) 372 (176) 4,496 (2,122) 17,075 (8,058) 12,900 (6,088) 372 (176) Carryout 131 (62) 93 (44) Office 157 (74) 117 (55) 2,100 (991) 2,100 (991) 117 (55) Utility 132 (62) 63 (30) 63 (30) There is very little guidance for modeling kitchen exhaust hood systems for energy savings calculations. The only guidance in 90.1-2004 is in Section 6.5.7, which requires that at least 50% of the make-up air for hoods larger than 5000 cfm be provided by uncooled and heated to no more than 60ºF. The Code of Federal Regulations Volume 71, Number 232 states that kitchen ventilation systems are to be included as part of the HVAC system for energy savings calculations (NARA 2006). With the lack of specific guidance on what the baseline exhaust system should be, we used the typical design for the Army dining facility as the baseline. This design incorporates some improvements in layout and hood design from previous designs. Establishing the baseline is very important because the exhaust hoods and the make-up air requirements constitute a large portion of the energy consumption in the building. There are 10 exhaust hoods for food preparation and one for the dish washer in this dining facility model. Table 7 lists the exhaust hoods and the characteristics for the baseline model. The baseline flow rates, fan pressure, and fan power were taken from the manufacturers equipment cut sheets for the model building used for this study. There was no cut sheet for the double island hood in the kitchen. It was assumed that this hood was 53 ft (16.2 m), counting both sides, and had a flow of 250 cfm/linear 10 Energy and Water Conservation Design Requirements for SRM Projects foot (387 L/s/m) for a total flow of 13,250 cfm (6,253 L/s). The hood duty categories were determined based on Table 1 from the Kitchen Ventilation chapter in the ASHRAE HVAC Applications Handbook (ASHRAE 2007). The flow per unit length was determined from the flow and length specified in the manufacturers cut sheets and they agree with the minimum flow ranges specified in Table 2 of the Kitchen Ventilation chapter in the HVAC Applications Handbook. Table 7. Baseline Exhaust Hood Air Flows. Zone Hood Duty Length ft (m) Flow per Length cfm/ft (L/s/m) Flow cfm (L/s) Static Press. in w.g. (Pa) Fan Power (kW) Total Fan Eff. Dishwashing Dishwasher Light Kitchen Double Island Medium 53.0 (16.2) 250 (387) 13,250 (6,253) 750 (354) 2 (426) 4.301 0.67 Carryout Wall-Mounted Medium 8.5 (2.6) 247 (382) 2,100 (991) 2 (426) 0.739 0.62 Servery Wall-Mounted Medium 5.5 (1.7) 350 (542) 1,925 (908) 2 (516) 0.747 0.67 Single Island Medium 7.0 (2.1) 300 (465) 2,100 (991) 2 (426) 0.677 0.67 Single Island Heavy 5.0 (1.5) 350 (542) 1,750 (826) 2 (426) 0.614 0.62 Single Island Medium 7.0 (2.1) 300 (465) 2,100 (991) 2 (426) 0.739 0.62 Single Island Medium 7.0 (2.1) 300 (465) 2,100 (991) 2 (426) 0.739 0.62 Wall-Mounted hood over fryer Medium 7.0 (2.1) 300 (465) 2,100 (991) 2 (426) 0.739 0.62 Wall-Mounted Medium 9.0 (2.7) 250 (387) 2,250 (1,062) 1 (298) 0.555 0.64 Bake shop Light 11.0 (3.4) 250 (387) 2,750 (1,298) 1 (292) 0.678 0.63 Servery Total 17,075 (8,058) 5.488 Building Total 32,425 (15,303) 10.528 There are two limitations in EnergyPlus version 2.1 that forced a workaround for the exhaust fans and make-up air. Exhaust fans are only controlled with an on–off schedule and cannot have a fractional schedule, which makes it impossible to model the various fans in the servery turning on and off at different times. In addition, EnergyPlus does not account for the transfer air from the dining zone when calculating the outside air requirements. EnergyPlus determines the outside air as the maximum of the exhaust fan flow rate and the minimum outside air schedule times the peak outside air flow rate without consideration of the transfer air. The outside air requirements for the servery goes up and down as the various exhaust fans and the transfer air turn on and off on different schedules. To get around this problem, the hourly energy use of the exhaust fans was calculated in a spreadsheet then entered in the EnergyPlus model as an external load to the zones. The outside air requirements were entered with an hourly schedule. The exhaust fan energy was then moved from the external load to the fan energy with post-processing. Results The annual energy use intensity for each climate as simulated by EnergyPlus forms the baseline energy budget. The target energy budget is 70% of these baseline values. Table 8 lists the site energy use intensities (EUI) with and without plug and process loads for the baseline and target energy budgets for each climate zone. Figure 8 shows breakouts of the energy consumption by end use. 11 Energy and Water Conservation Design Requirements for SRM Projects Table 8. Energy Budgets by Climate Zone. With Process Loads Climate Zone City Without Process Loads Baseline kBtu/ft2 (MJ/m2) Target kBtu/ft2 (MJ/m2) Baseline kBtu/ft2 (MJ/m2) Target kBtu/ft2 (MJ/m2) 1A Miami, FL 355 (1,229) 249 (862) 153 (530) 107 (370) 2A Houston, TX 363 (1,256) 254 (879) 154 (533) 108 (374) 2B Phoenix, AZ 348 (1,205) 244 (845) 143 (495) 100 (346) 3A Memphis, TN 375 (1,298) 263 (910) 161 (557) 113 (391) 3B El Paso, TX 355 (1,229) 248 (858) 143 (495) 100 (346) 3C San Francisco, CA 331 (1,146) 232 (803) 112 (388) 78 (270) 4A Baltimore, MD 402 (1,391) 282 (976) 182 (630) 127 (440) 4B Albuquerque, NM 368 (1,274) 258 (893) 149 (516) 104 (360) 4C Seattle, WA 372 (1,288) 260 (900) 149 (516) 104 (360) 5A Chicago, IL 433 (1,499) 303 (1,049) 209 (723) 146 (505) 5B Colorado Springs, CO 393 (1,360) 275 (952) 168 (581) 117 (405) 6A Burlington, VT 464 (1,606) 325 (1,125) 236 (817) 165 (571) 6B Helena, MT 435 (1,506) 304 (1,052) 206 (713) 144 (498) 7A Duluth, MN 508 (1,758) 356 (1,232) 273 (945) 191 (661) 8A Fairbanks, AK 630 (2,181) 441 (1,526) 388 (1,343) 271 (938) Energy Conservation Measures Tables 16-16 and 16-17 show the annual energy savings intensity for each of the ECMs. The energy savings across all the ECMs in the final building are not additive because of the interactions between all of the building systems. The lighting and envelope ECMs were modeled separately and in combination to determine the best combinations by climate zone. Table 9. Energy Conservation Measures. ECM Envelope air tightness Description Improved building air leakage to 0.25 cfm/ft2 at 0.3 in w.g. (1.25 L/s/m2 at 75 Pa) Envelope insulation Used 30% Small Office Advanced Energy Design Guide insulation Envelope fenestration Used 30% Small Office Advanced Energy Design Guide windows Cool Roof Increased solar reflectance to 0.65 Improved lighting design Reduced lighting power densities Daylighting Added daylighting controls to the dining, servery, carryout, and office Ventilation hood end panels Added partial end panels on the kitchen hood and all wall-mounted hoods in the servery, bake shop, and carryout areas Eliminate single-island hoods Replaced single-island hoods with wall-mounted hoods in servery DCV ventilation hoods Added DCV to the hoods in the servery, carryout, and kitchen High efficiency HVAC Increased the efficiency of all HVAC and water heating equipment Low-flow pre-rinse nozzles Added low-flow pre-rinse nozzles – 1.2 gpm (0.076 L/s) Envelope Air Tightness. Based on input from building air tightness experts, the U.S. Army has proposed in their new construction regulations that the leakage rate must not exceed 0.25 cfm/ft2 at 0.3 in w.g. (1.25 L/s/m2 at 75 Pa), which was assumed for the energy efficient building models in this study. The energy savings for this ECM are small in all climates except for climate zones 6 and 8 where the savings reaches 6%. Improved Envelope. Tables 16-10 lists the recommended building envelope insulation levels and fenestration for the energy efficient building. The opaque envelope insulation recommendations follow Standard 90.1-2004 for climate zones 1 through 2B and the ASHRAE Small Office 30% Advanced 12 Energy and Water Conservation Design Requirements for SRM Projects Energy Design Guide (AEDG) (ASHRAE 2004b) for the other climate zones. The recommended fenestration follow Standard 90.1-2004 for climate zones 1 through 3C and follow the Small Office 30% AEDG for climate zones 4 through 8. The opaque envelope ECM shows very little savings in climate zone 3 and significant energy savings in the cold climates. This difference in windows shows negative energy savings in climate zone 1A because of the higher solar heat gain in the AEDG windows. A high roof solar reflectance was modeled as a separate case. The baseline roof solar reflectance was 0.3 and the “cool roof” solar reflectance was 0.65. This ECM shows small energy savings for climate zones 1, 2, and 4B and a very small savings in 3A. There is negative energy savings in the other climate zones. The energy use in this building is driven by the requirements to treat the make-up air; therefore, this ECM has a small impact compared to other building types. 13 Energy and Water Conservation Design Requirements for SRM Projects Table 10. Envelope Conservation Measures Item Component(1) Climate Zones 1 Roof 2 3 4 5 6 7 8 Assembly Max U-value U-0.0634 U-0.0634 U-0.0481 U-0.0481 U-0.0481 U-0.0388 U-0.0388 U-0.0388 Insulation Entirely Above Deck R-15ci R-15ci R-20ci R-20ci R-20ci R-25ci R-25ci R-25ci Attic and Other R-19 R-19 R-30 R-30 R-30 R-38 R-38 R-38 Solar Reflectance (2) 0.65 0.65 0.65 0.65 0.65 0.30 0.30 0.30 Assembly Max U-value U-0.1242 U-0.1242 U-0.0847 U-0.0676 U-0.0676 U-0.0676 U-0.0676 U-0.0391 Mass R-6.5ci R-6.5ci R-10 R-13 R-13 R-13 R-13 R-11.4 + R-3.0ci Steel Framed R-13 R-13 R-13 + R-3.8ci R-13 + R-7.5ci R-13 + R-7.5ci R-13 + R-7.5ci R-13 + R-7.5ci R-13 + R-18.8ci Wood Framed and Other R-13 R-13 R-13 R-13 + R-3.8ci R-13 + R-3.8ci R-13 + R-3.8ci R-13 + R-3.8ci R-13 + R-19.5ci Assembly Max U-value U-0.1067 U-0.1067 U-0.0739 U-0.0739 U-0.0521 U-0.0377 U-0.0377 U-0.0377 Mass R-6.3ci R-6.3ci R-10.4ci. R-10.4ci. R-16.7ci. R-25.1ci. R-25.1ci. R-25.1ci. Steel Joists R-13 R-13 R-13 R-13 R-19 R-30 R-30 R-30 Wood Framed and Others R-13 R-13 R-13 R-13 R-19 R-30 R-30 R-30 Assembly Max F-value; F-0.730 ; F-0.730 ; F-0.730 ; F-0.520 ; F-0.520 ; F-0.510 ; F-0.510 ; F-0.434 ; NR (3) NR (3) NR (3) R-15.0 for 24 in. R-15.0 for 24 in. R-20.0 for 24 in. R-20.0 for 24 in. R-20.0 for 48 in. F-1.020; F-1.020; F-0.860 ; F-0.843 ; F-0.688; F-0.688; F-0.671; F-0.671; R-7.5 for 12 in R-7.5 for 12 in R-15.0 for 24 in. R-20 for 24 in. R-20.0 for 48 in R-20.0 for 48 in R-25.0 for 48 in R-25.0 for 48 in Swinging U-0.70 U-0.70 U-0.70 U-0.50 U-0.50 U-0.50 U-0.50 U-0.50 Non-swinging U-1.45 U-1.45 U-1.45 U-0.50 U-0.50 U-0.50 U-0.50 U-0.50 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 0.25 cfm/ft2 Vertical Glazing Window to Wall Ratio < 20% (WWR) < 20% < 20% < 20% < 20% < 20% < 20% < 20% Thermal U-1.22 transmittance (Assembly Maximum) U-1.22 U-0.57 U-0.42 U-0.42 U-0.42 U-0.33 U-0.33 Solar heat gain coefficient (SHGC) 0.25 0.25 0.37 0.39 0.39 0.39 NR (3) NR (3) South Overhangs NR (3) NR (3) NR (3) NR (3) NR (3) NR (3) NR (3) NR (3) Percent Roof Area ≤4% Walls Floors Over Unconditioned Space Slab-on-Grade Unheated Assembly Max F-value; Heated Doors Air Tightness (4) Max Leakage at ±75Pa Blower Test Pressures Skylights (Dining and Servery) ≤4% ≤4% ≤4% ≤4% ≤4% ≤4% None Thermal U-1.36 transmittance (Assembly Maximum) U-1.36 U-0.69 U-0.69 U-0.69 U-0.69 U-0.69 NR (3) Solar heat gain coefficient (SHGC) 0.19 0.19 0.34 0.39 0.49 0.64 NR (3) 0.19 14 Energy and Water Conservation Design Requirements for SRM Projects Improved Lighting Design and Daylighting. Table 11 lists the interior lighting power densities (LPD) for the baseline and the energy efficient model for each space. The final column in this table lists the space type from Standard 90.1 Table 9.6.1. Daylighting controls were modeled in the servery and the dining area as an energy conservation measure with a minimum illuminance level of 30 fc (300 lux). Table 15 lists the energy savings by location for reduced LPD and for reduced LPD with daylighting. The energy savings are best for the warmer climates. The energy performance in Fairbanks was better without the skylights; therefore there are no skylights and no daylighting in the final energy efficient model for Fairbanks. Occupancy sensors were not included in the simulations because the actual occupancy patterns for the spaces were unknown during this analysis. However, they should be included in all zones that are unoccupied for more than 20% of the building occupied period (3 a.m. to 8 p.m.). Zones that are possible candidates for occupancy sensors include restrooms, office, employee break room, utility rooms, janitor’s closets, and storage rooms. Table 11. Building Lighting Power. Baseline Zone Efficient Model 90.1-2004 Space Type W/ft2 (W/m2) W W/ft2 (W/m2) W Dining 0.9 (9.68) 7,183 0.8 (8.61) 6,383 Dining area Storage/Receiving 0.8 (8.61) 2,098 0.8 (8.61) 2,098 Active Storage Dishwashing 1.2 (12.91) 1,344 1.0 (10.76) 1,120 Food Preparation Kitchen 1.2 (12.91) 3,315 1.1 (11.84) 3,039 Food Preparation Servery 1.2 (12.91) 5,131 1.0 (10.76) 4,276 Food Preparation Entry/Circulation 1.3 (13.99) 4,277 1.0 (10.76) 3,290 Lobby Carryout 1.2 (12.91) 1,253 1.0 (10.76) 1,044 Food Preparation Office 1.1 (11.84) 1,588 0.9 (9.68) 1,300 Office Utility 1.5 (16.14) 1,580 1.0 (10.76) 1,053 Elec/Mech Total 27,759 23,596 Ventilation. Table 12 lists the building infiltration, ventilation, and outside air requirements for the final energy efficient model. Three ECMs were applied to the exhaust hoods: addition of end panels, replacement of single island hoods with wall-mounted or back-shelf hoods, and application of demand controlled ventilation (DCV). Table 13 lists the characteristics of the exhaust hoods with all the ECMs applied. The first ECM was to add partial or full end panels to the kitchen hood and all wall-mounted hoods in the servery and carryout zones. It was assumed that this ECM would reduce the flow requirements for all affected hoods to the low end of the minimum flow range in Table 2 of the Kitchen Ventilation chapter in the ASHRAE HVAC Applications Handbook (ASHRAE 2007). The second ECM was to replace the single island hoods in the servery with wall-mounted, canopy hoods by adding full back and partial side walls. The back walls can be transparent to allow visibility from the serving line. The final ECM was to include DCV, which reduces the exhaust flow between heavy cooking periods. It was assumed that the exhaust flow was reduced by half between the heavy cooking periods. A schedule for the DCV operation was derived from analysis of the cooking loads. Actual savings from DCV may vary depending on the effectiveness of the DCV controller and the amount of off peak cooking time. Another ECM that affects the transfer air from the dining zone is the reduced infiltration from a tighter building, which affects the make-up air requirements in the servery. Tables 16-6 and 1612 show the infiltration and the transfer air from the dining zone. The reduced infiltration leaves more of the ventilation air in the dining zone available to be transferred to the servery. The maximum outside air requirement in Tables 16-6 and 16-12 for the servery is higher than the servery exhaust minus the dining transfer air. Each of the exhaust hoods in the servery and the dining transfer air operate on different schedules. The maximum outside air requirement in the servery occurs in the morning when some of the exhaust fans are on and before the dining outside air system is turned 15 Energy and Water Conservation Design Requirements for SRM Projects on. Table 12. Efficient Building Model Outside Air Requirements. Zone Infiltration cfm (L/s) 62.1-2004 Ventilation cfm (L/s) Dining 480 (227) 5,187 (2,448) Storage/Receiving 155 (73) 315 (149) Transfer Air cfm (L/s) Exhaust Hood cfm (L/s) -4,755 (2,244) Maximum Outside Air cfm (L/s) 5,187 (2,448) 315 (149) Dishwashing 48 (23) 784 (370) 750 (354) 750 (354) Kitchen 119 (56) 1,934 (913) 10,600 (5,003) 10,600 (5,003) Servery 184 (87) 1,145 (540) 11,400 (5,380) 7,875 (3,717) Entry/Circulation 184 (87) 372 (176) Carryout 82 (39) 93 (44) 1,700 (802) 1,700 (802) 4,755 (2,244) 372 (176) Office 98 (46) 117 (55) 117 (55) Utility 82 (39) 63 (30) 63 (30) Table 13. Energy Efficient Exhaust Hood Air Flows. Zone Hood Duty Dishwashing Dishwasher Light Kitchen Double Island Medium Length ft (m) Flow per Length cfm/ft (L/s/m) Flow cfm (L/s) Static Press. in w.g. (Pa) Fan Power Total Fan (kW) Eff. 750 (354) 53.0 (16.2) 200 (310) 10,600 (5,003) 1.20 (298) 2.641 0.63 Carryout Wall-Mounted Medium 8.5 (2.6) 200 (310) 1,700 (802) 1.22 (304) 0.465 0.58 Servery Wall-Mounted Medium 5.5 (1.7) 200 (310) 1,100 (519) 0.85 (211) 0.222 0.57 Wall-Mounted Medium 7.0 (2.1) 200 (310) 1,400 (661) 0.90 (223) 0.283 0.60 Wall-Mounted Heavy 5.0 (1.5) 250 (387) 1,250 (590) 1.00 (249) 0.296 0.56 Wall-Mounted Medium 7.0 (2.1) 200 (310) 1,400 (661) 0.90 (223) 0.309 0.55 Wall-Mounted Medium 7.0 (2.1) 200 (310) 1,400 (661) 0.90 (223) 0.309 0.55 Wall-Mounted hood over fryer Medium 7.0 (2.1) 200 (310) 1,400 (661) 0.90 (223) 0.309 0.55 Wall-Mounted Medium 9.0 (2.7) 200 (310) 1,800 (850) 0.84 (209) 0.347 0.60 Bake shop Light 11.0 (3.4) 150 (232) 1,650 (779) 0.52 (129) 0.240 0.53 Servery Total 11,400 (5,380) 2.315 Building Total 23,700 (11,185) 5.422 Figure 10 shows (and Table 16 lists) the energy savings from reducing the hood exhaust rates. The savings are higher in the colder climates because of the large temperature difference between the outside air and the zone air temperatures. Installing end panels provides the largest energy savings for climate zones 7 and 8. Replacing the single island hoods with wall-mounted hoods showed small savings in the warm climates and larger savings in the cold climates. Including DCV on the hoods also shows small savings in the warm climates and significant savings in the cold climates. If the singleisland hoods are not replaced, this ECM will have a larger effect in all climates. The savings associated with this ECM strongly depend on the number of hours with reduced flow and the reduction in flow. Further analysis should be completed if the operating conditions are different than those assumed in this study. The design exhaust rate for kitchen ventilation systems depends on the hood style along with subtle construction features and enhancements (e.g., return flanges along the inside edge of the hood, integral side skirts). Wall-mounted canopy hoods, island (single or double) canopy hoods, and proximity (backshelf, pass-over, or eyebrow) hoods all have different capture areas and are mounted at different heights and horizontal positions relative to the cooking equipment (Figure 11). Generally, for the identical (thermal plume) challenge, a single-island canopy hood requires more exhaust than a wallmounted canopy hood, and a wall-mounted canopy hood requires more exhaust than a proximity 16 Energy and Water Conservation Design Requirements for SRM Projects (backshelf) hood. The performance of a double-island canopy tends to emulate the performance of two back-to-back wall-canopy hoods, although the lack of a physical barrier between the two hood sections makes the configuration more susceptible to cross drafts. Where applicable, the following best-design practices should be incorporated within the exhaust system design and specifications to ensure that capture and containment performance of the hood is satisfactorily at the reduced exhaust rate: 1. Incorporate partial side panels or end walls (Figure 12a and 16-12b). 2. Maximize overhang and minimize clearance between appliance and rear wall (Figure 12c and 16-12d). 3. Position heavy duty equipment (e.g., broilers) in middle of the hood and light duty (e.g., ovens, kettles) at the end of the cook line. 4. Specify wall-mounted canopy hoods instead of single-island canopies. 5. Specify back-shelf (i.e., proximity hoods) over short-order equipment such as griddles and fryers. 6. introduce low-velocity makeup air near hoods (e.g., no 4-way diffusers in kitchens). 7. Maximize transfer air. 8. Incorporate demand ventilation controls High Efficiency HVAC. Three HVAC systems were modeled as improvements to the baseline system: high efficiency PTAC, packaged variable air volume (VAV) with an air cooled chiller, and a packaged VAV with a water cooled chiller. All three improved systems showed similar performance. The high efficiency PTAC was included in the final models. Table 14 lists the four HVAC systems parameters. This ECM shows significant energy savings in all climates. For climate zones 1 through 3 and 4B, it is the single highest saving ECM. Table 14. HVAC systems. Baseline PTAC Parameter High Eff. PTAC Size range 1000Btu/h (kW) 135 – 240 (39 – 70) 135 – 240 (39 – 70) EER 9.7 12 PVAV Air Cooled Chiller PVAV Water Cooled Chiller COP 2.84 3.52 3.7 7.0 COP w/o supply fan 2.95 3.70 N/A N/A Total fan efficiency 0.2 0.45 0.45 0.45 Heating source Gas furnace Gas furnace Gas boiler Gas boiler Heating efficiency 0.8 0.9 0.94 0.94 Pump efficiency N/A N/A 0.90 0.90 SHW gas boiler efficiency 0.8 0.94 0.94 0.94 Service Hot Water. Service hot water use is 15% to 20% of the total building energy consumption. The SHW use in the food preparation and dish wash areas is a process load and not included in the energy savings calculations. However, a 94% efficient boiler was included in the final energy efficient design model. Another ECM for saving hot water is to install low flow prerinse nozzles with a flow rate of 1.2 gpm (0.076 L/s). This ECM was not included in the final model because the SHW for washing is considered a process load. 17 Energy and Water Conservation Design Requirements for SRM Projects CZ City Reduced LPD Daylighting Reduced LPD Cool Roof AEDG 30% SO Fenestration Envelope Air Tightness AEDG 30% SO Opaque Envelope Table 15. Annual Energy Savings for Individual ECMs (kBtu/ft2) 1A Miami, FL 0.4 (1.4) 0.0 (0.0) -0.6 (-2.1) 0.5 (1.7) 4.2 (14.5) 9.1 (31.5) 2A Houston, TX 1.1 (3.8) 0.0 (0.0) 0.6 (2.1) 0.5 (1.7) 3.5 (12.1) 8.7 (30.1) 2B Phoenix, AZ 0.7 (2.4) 0.0 (0.0) 0.4 (1.4) 1.1 (3.8) 3.5 (12.1) 8.4 (29.1) 3A Memphis, TN 1.5 (5.2) 0.9 (3.1) 0.3 (1.0) 0.1 (0.3) 3.0 (10.4) 7.7 (26.7) 3B El Paso, TX 0.8 (2.8) 1.0 (3.5) 0.3 (1.0) -0.2 (-0.7) 3.4 (11.8) 8.4 (29.1) 3C San Francisco, CA 1.1 (3.8) 1.3 (4.5) 0.9 (3.1) -0.5 (-1.7) 2.4 (8.3) 6.7 (23.2) 4A Baltimore, MD 2.0 (6.9) 2.3 (8.0) 0.6 (2.1) -0.2 (-0.7) 2.4 (8.3) 6.3 (21.8) 4B Albuquerque, NM 1.3 (4.5) 2.2 (7.6) 0.3 (1.0) 0.4 (1.4) 2.5 (8.7) 6.8 (23.5) 4C Seattle, WA 2.0 (6.9) 2.5 (8.7) 0.5 (1.7) -0.3 (-1.0) 1.8 (6.2) 4.7 (16.3) 5A Chicago, IL 2.6 (9.0) 2.1 (7.3) 0.9 (3.1) -0.4 (-1.4) 1.9 (6.6) 5.3 (18.3) 5B Colo. Springs, CO 2.0 (6.9) 2.2 (7.6) 0.7 (2.4) -0.6 (-2.1) 2.1 (7.3) 5.7 (19.7) 6A Burlington, VT 3.2 (11.1) 2.6 (9.0) 1.2 (4.2) -0.8 (-2.8) 1.7 (5.9) 4.8 (16.6) 6B Helena, MT 3.0 (10.4) 3.1 (10.7) 1.2 (4.2) -0.6 (-2.1) 1.6 (5.5) 4.3 (14.9) 7A Duluth, MN 4.0 (13.8) 2.7 (9.3) 2.2 (7.6) -1.1 (-3.8) 1.4 (4.8) 3.7 (12.8) 8A Fairbanks, AK 5.9 (20.4) 7.2 (24.9) 1.7 (5.9) -0.5 (-1.7) 1.2 (4.2) 2.2 (7.6) Low-Flow Nozzles High Eff. HVAC First two hood ECMs plus DCV on all Hoods City DCV Kitchen Hoods on top of End Panels CZ DCV Hoods in Servery & Carryout on top of End Panels and Single Island End Panels on all Hoods Replace Single Island Hoods in Servery Table 16. Annual Energy Savings for Individual ECMs 1000Btu/ft2 (MJ/m2) 1A Miami, FL 7.2 (24.9) 2.4 (8.3) 1.8 (6.2) 0.6 (2.1) 2.4 (8.3) 40.0 (138.5) 2.7 (9.3) 2A Houston, TX 10.3 (35.7) 3.9 (13.5) 1.3 (4.5) 3.5 (12.1) 4.8 (16.6) 35.0 (121.1) 3.0 (10.4) 2.9 (10.0) 2B Phoenix, AZ 8.7 (30.1) 2.8 (9.7) 0.4 (1.4) 3.4 (11.8) 3.8 (13.2) 34.0 (117.7) 3A Memphis, TN 18.1 (62.6) 5.9 (20.4) 1.4 (4.8) 6.8 (23.5) 8.3 (28.7) 31.0 (107.3) 3.3 (11.4) 3B El Paso, TX 11.0 (38.1) 3.4 (11.8) -0.3 (-1.0) 4.6 (15.9) 4.3 (14.9) 32.0 (110.8) 3.2 (11.1) 3C San Francisco, CA 15.0 (51.9) 3.7 (12.8) -0.5 (-1.7) 6.7 (23.2) 6.2 (21.5) 19.0 (65.8) 3.4 (11.8) 4A Baltimore, MD 25.8 (89.3) 8.9 (30.8) 2.9 (10.0) 10.8 (37.4) 13.6 (47.1) 30.0 (103.8) 3.6 (12.5) 4B Albuquerque, NM 18.6 (64.4) 6.1 (21.1) 1.3 (4.5) 8.4 (29.1) 9.7 (33.6) 27.0 (93.5) 3.5 (12.1) 4C Seattle, WA 24.8 (85.8) 8.0 (27.7) 1.3 (4.5) 10.9 (37.7) 12.2 (42.2) 21.0 (72.7) 3.6 (12.5) 5A Chicago, IL 32.4 (112.1) 11.5 (39.8) 4.8 (16.6) 13.8 (47.8) 18.7 (64.7) 31.0 (107.3) 3.7 (12.8) 5B Colo. Springs, CO 24.2 (83.8) 8.2 (28.4) 2.6 (9.0) 11.5 (39.8) 14.1 (48.8) 28.0 (96.9) 3.8 (13.2) 6A Burlington, VT 38.7 (134.0) 13.8 (47.8) 7.0 (24.2) 16.9 (58.5) 23.9 (82.7) 32.0 (110.8) 3.9 (13.5) 6B Helena, MT 34.2 (118.4) 12.1 (41.9) 5.5 (19.0) 15.7 (54.3) 21.2 (73.4) 28.0 (96.9) 3.9 (13.5) 7A Duluth, MN 47.8 (165.4) 17.3 (59.9) 9.5 (32.9) 21.1 (73.0) 30.6 (105.9) 34.0 (117.7) 4.2 (14.5) 8A Fairbanks, AK 69.7 (241.3) 25.5 (88.3) 17.3 (59.9) 30.4 (105.2) 47.7 (165.1) 45.0 (155.8) 4.6 (15.9) 18 Energy and Water Conservation Design Requirements for SRM Projects Total Energy Savings with Recommended Technology Sets The energy savings for the final energy efficient solutions are shown with and without the plug and process loads in Tables 16-17 and 16-18. The energy savings ranges from 35% to 48%. Table 19 lists the combinations of best performing solutions for each climate zone. Table 17. Final Energy Efficient Design Solutions without Process Loads CZ 1A City Baseline 1000Btu/ft2 (MJ/m2) Final Energy Efficient Solution 1000Btu/ft2 (MJ/m2) Energy Savings Miami, FL 153 (530) 100 (346) 35% 2A Houston, TX 154 (533) 97 (336) 37% 2B Phoenix, AZ 143 (495) 90 (312) 37% 3A Memphis, TN 161 (557) 92 (318) 43% 3B El Paso, TX 143 (495) 82 (284) 42% 3C San Francisco, CA 112 (388) 60 (208) 46% 4A Baltimore, MD 182 (630) 99 (343) 46% 4B Albuquerque, NM 149 (516) 80 (277) 46% 4C Seattle, WA 149 (516) 77 (267) 48% 5A Chicago, IL 209 (723) 112 (388) 46% 5B Colorado Springs, CO 168 (581) 88 (305) 48% 6A Burlington, VT 236 (817) 124 (429) 47% 6B Helena, MT 206 (713) 107 (370) 48% 7A Duluth, MN 273 (945) 142 (492) 48% 8A Fairbanks, AK 388 (1,343) 203 (703) 48% Table 18. Final Energy Efficient Design Solutions with Process Loads CZ 1A City Baseline 1000Btu/ft2 (MJ/m2) Final Energy Efficient Solution 1000Btu/ft2 (MJ/m2) Energy Savings Miami, FL 355 (1,229) 295 (1,021) 17% 2A Houston, TX 363 (1,256) 297 (1,028) 18% 2B Phoenix, AZ 348 (1,205) 287 (993) 17% 3A Memphis, TN 375 (1,298) 297 (1,028) 21% 3B El Paso, TX 355 (1,229) 286 (990) 19% 3C San Francisco, CA 331 (1,146) 269 (931) 19% 4A Baltimore, MD 402 (1,391) 309 (1,070) 23% 4B Albuquerque, NM 368 (1,274) 290 (1,004) 21% 4C Seattle, WA 372 (1,288) 290 (1,004) 22% 5A Chicago, IL 433 (1,499) 326 (1,128) 25% 5B Colorado Springs, CO 393 (1,360) 303 (1,049) 23% 6A Burlington, VT 464 (1,606) 341 (1,180) 26% 6B Helena, MT 435 (1,506) 324 (1,121) 25% 7A Duluth, MN 508 (1,758) 365 (1,263) 28% 8A Fairbanks, AK 630 (2,181) 432 (1,495) 31% 19 Energy and Water Conservation Design Requirements for SRM Projects 1A High Eff. HVAC Kitchen DCV Hoods Servery DCV Hoods Replace Single Island Hoods Hood End Panels Daylighting Reduced LPD Cool Roof Skylights AEDG 30% SO Fenestration City AEDG 30% SO Insulation Zone Envelope Air Tightness Table 19. Summary of ECMs in Final Models (grey shading indicates not recommended or investigate on a case by case basis) Miami, FL 2A Houston, TX 2B Phoenix, AZ 3A Memphis, TN 3B El Paso, TX 3C San Francisco, CA 4A Baltimore, MD 4B Albuquerque, NM 4C Seattle, WA 5A Chicago, IL 5B Colo. Springs, CO 6A Burlington, VT 6B Helena, MT 7A Duluth, MN 8A Fairbanks, AK Energy savings associated with effectively reducing the average kitchen exhaust ventilation rate (and the associated makeup air requirements) represent a very significant set of ECMs for Army dining facilities. Installing partial end panels or skirts on all wall-canopy hoods in the kitchen and servery shows significant energy savings in all climate zones, especially the cold climates. Similarly, replacing single-island canopy hoods with wall-mounted canopy hoods (or proximity style back-shelf hoods on short-order cooklines) generates significant savings in the cold climates. Overlaying demand controlled ventilation on all ventilation hoods in the kitchen saves energy in all climate zones, particularly the hot and cold climates. Applied to the servery hoods, there are cases where the reduction in average ventilation rate did not generate savings in the mild climate zones. Effectively, all three kitchen ventilation ECMs facilitate a reduction in the average exhaust and makeup air flow rates and generate significant energy savings. In moderate climate zones, the benefits of reduced makeup air heating and cooling may be offset by the “economizer” effect of having higher exhaust rates during extended shoulder seasons. Installing high efficiency HVAC (PTAC, 12.0 EER (3.52 COP); 0.9 Et gas heater; 0.94 Et gas boiler Vs PTAC, 9.7 EER (2.84 COP); 0.8 Et gas heater; 0.8 Et gas boiler) in the baseline case per the ASHRAE Standard 90.1-2004 requirements shows significant energy savings in all climates. It shows the highest savings for climate zones 1 through 3 and 4B. Installing Low-Flow Pre-Rinse Nozzles, 1.2 gpm, in each of the storage and receiving, dish wash, and kitchen zones is very easy to implement and shows energy savings in all climates. 20 Energy and Water Conservation Design Requirements for SRM Projects Summary and Discussion EPAct 2005 sets energy performance requirements to reduce energy use in federal facilities. The OACSIM and USACE are determined to meet these requirements for the large number of new buildings to be constructed in the next few years by setting target energy budgets. USACE also wanted a prescriptive path to meet or exceed these energy saving requirements, and also to use these technologies to improve soldiers’ and workers’ productivity and wellbeing, as well as improving buildings’ sustainability. With these objectives in mind, design guides for the most typical categories of Army buildings were developed. This paper presents the results of developing target energy budgets and energy design guide for Dining Facilities. The approach for other seven building types is similar to that presented in this paper. Information on target energy budgets and design guidelines for Unaccompanied Enlisted Personal Housing (UEPH) barracks and for TEMF are presented in two companion papers (Herron et al. 2009 and Zhivov et al. 2009). For the model DFAC building energy savings against the baseline vary between 35% and 48% depending on the climate. The most effective energy conservation measures include strategies to reduce the ventilation hood exhaust flows, high efficiency HVAC systems, improved lighting design, and daylighting. Results of this study were implemented through the Army’s standard Bid-Build process in late 2008 by incorporation in RFP target energy budgets by climate zone and sets of technologies allowing to meet these budgets. Designs and construction using RFP having new requirements began in 2008. They allow either a custom design following target energy budgets and using required set of technologies with a mandatory proof of compliance with energy targets, or contractors can use a complete set of technologies included in the prescriptive path, which does not require a proof of compliance. Actual and predicted energy savings strongly depend upon the climate, building orientation and (for specific building design), will vary. However, implementation of developed energy budgets and a sets of technologies included in the prescriptive path streamlines the facility design and construction process and ensures that newly constructed facilities comply with the intent of the EPAct 2005 without jeopardizing their functional quality. Acknowledgement This paper is based on the results of the project “Energy Benchmarks for Army Facilities” conducted for the Office of the Assistant Chief of Staff of the Installations Management (OACSIM) and the Headquarters, U.S. Army Corps of Engineers (HQUSACE). Information on the energy conservation technologies analyzed in this project was based on research data resulted from the IEA-ECBCS (International Energy Agency – Energy Conservation in Buildings and Community Systems) Annex 46 “Holistic Assessment Tool-kit on Energy Efficient Retrofit Measures for Government Buildings (EnERGo) financially supported by the OACSIM and Headquarters, Installation Management Agency (HQIMA). ASHRAE Technical Committee 7.6 Working Group members and the Annex 46 Subtask B members contributed to the generation of the Energy Conservation Measures, their screening conditions and the industrial model building parameters. The authors express their gratitude to MTG group members. 21 Energy and Water Conservation Design Requirements for SRM Projects References ASHRAE 2004a. ANSI/ASHRAE/IESNA Standard 90.1-2004 Energy Standard for Buildings except Low-Rise Residential Buildings. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. ASHRAE 2004b. Advanced Energy Design Guide for Small Office Buildings. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. ASHRAE 2004c. ANSI/ASHRAE Standard 62.1-2004 Ventilation for Acceptable Indoor Air Quality. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. ASHRAE 2007. ASHRAE Handbook – HVAC Applications. Atlanta, GA: American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. Briggs, R.S., R.G. Lucas, and T. Taylor, 2003. Climate Classification for Building Energy Codes and Standards: Part 2 - Zone Definitions, Maps and Comparisons, Technical and Symposium Papers, ASHRAE Winter Meeting, Chicago, IL, January, 2003. DOE 2007. 2007 Buildings Energy Data Book. http://buildingsdatabook.eere.energy.gov/. Washington, DC: U.S. Department of Energy. DOE 2008. EnergyPlus Energy Simulation Software. www.eere.energy.gov/buildings/energyplus/. Washington, DC: U.S. Department of Energy. EPA 2008. Website listing qualified Energy Star categories and modules of commercial foodservice equipment. http://www.energystar.gov/index.cfm?c=commercial_food_service.commercial_food_service. Washington, DC: U.S. Environmental Protection Agency. FEMP 2008. Federal Energy Management Program (FEMP) Energy Efficient Product Recommendations. http://www1.eere.energy.gov/femp/procurement/eep_requirements.html. Washington, DC: U.S. Department of Energy. FSTC 2004a. Food Service Technology Center Design Guide Series on Commercial Kitchen Ventilation. http://www.fishnick.com/equipment/ckv/designguides/. Pacific Gas & Electric Company, San Ramon, CA. FSTC 2004b. Food Service Technology Center Design Guide Series on Commercial Kitchen Ventilation. http://www.fishnick.com/saveenergy/rebates/. Pacific Gas & Electric Company, San Ramon, CA. Herron, D, A. Zhivov, and M. Deru. 2009. Energy Design Guides for Army Barracks. ASHRAE Transactions. ASHRAE Annual Meeting, Louisville, KY, June, 2009. Marion, W. and Wilcox, S. 1995. Solar Radiation Data Manual for Buildings. TP-463-7904. http://rredc.nrel.gov/solar/pubs/bluebook/. Golden, CO: National Renewable Energy Laboratory. NARA 2006. Federal Register Vol. 71, No. 232. pp.70275-70284. Washington, D.C.: National Archives and Records Administration. 22 Energy and Water Conservation Design Requirements for SRM Projects Zhivov, A., D. Herron, and M. Deru. 2009. Achieving Energy Efficiency and Improving Indoor Air Quality In Army Maintenance Facilities. ASHRAE Transactions. ASHRAE Annual Meeting, Louisville, KY, June, 2009. 23 Energy and Water Conservation Design Requirements for SRM Projects Figure 1. Sketch of a Proposed Army Dining Facility Figure 2. Proposed DFAC floor plan from the Army 24 Energy and Water Conservation Design Requirements for SRM Projects Carryout Entry/ Circulation Office Servery Dishwash Utility Kitchen Storage Dining Figure 3. Thermal zoning for the DFAC energy model Figure 4. Rendering of the energy simulation model for the DFAC 25 Energy and Water Conservation Design Requirements for SRM Projects 120 Kitchen Servery Dining Carry Out Bake Shop Dishwashing 100 Electricity (kWh) 80 60 40 20 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Hour Figure 5. Daily process load electricity consumption profiles 200 180 Gas Consumption (kBtu) 160 Kitchen Servery Carry Out Bake Shop 140 120 100 80 60 40 20 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Hour Figure 6. Daily process load gas consumption profiles 26 Energy and Water Conservation Design Requirements for SRM Projects 350 Total Gas (kBtu) Total Elec (kWh) Energy Consumption 300 250 200 150 100 50 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Hour Figure 7. Daily total process load consumption profiles of electricity and gas Heating Cooling SWH Pumps Fans Refrigeration Interior Lighting Interior Equipment Gas Interior Equipment Elec 5,000 4,000 3,500 3,000 2,500 2,000 1,500 1,000 500 H ia m i, 1A ou st on ,2 A Ph oe ni x, 2B M em ph is ,3 A El P Sa as o, n Fr 3B an cis co ,3 Ba C l ti m or Al e, bu 4A qu er qu e, 4B Se at tle ,4 C C hi ca C go ol ,5 o. A Sp ri n gs ,5 Bu B rl i ng to n, 6A H el en a, 6B D ul ut h, Fa 7A irb an ks ,8 A 0 M Annual Total Site Energy (MWh) 4,500 Figure 8. Energy use by end use for the baseline building 27 Energy and Water Conservation Design Requirements for SRM Projects 3,500 Annual Site Energy (kWh) 3,000 2,500 2,000 Heating Cooling 0.5% SHW Pumps Fans Refrigeration Interior Lighting 1,500 1,000 500 M ia m Ho i, 1 A us to Ph n , 2 A oe M nix, em 2 ph B is, El Sa Pa 3A n so Fr ,3 an B ci sc Ba o, lt 3 Al imo C bu re , qu er 4A qu e, Se 4B at tle ,4 C C Co h ic a go lo .S ,5 pr A in Bu gs , rl i ng 5B to n He , 6 A le na ,6 Du B l u Fa th , irb 7A an ks ,8 A 0 Figure 9. Energy use by end use for regulated loads in the baseline building 50% 400 35% 250 30% 25% 200 20% 150 15% 100 Percent Energy Savings 40% 300 Reduced hood flow plus DCV on kitchen, servery, carryout Hood end panels Opaque Env., Reduced LPD, & daylighting Daylighting w/ reduced LPD Reduced LPD 10% Envelope 50 5% Air Tightness 0% m ou i, 1A st P h o n, oe 2A M ni x em , 2 ph B i Sa El s, 3 Pa A n Fr s an o, 3 ci B Ba sco ,3 l t i Al m bu o r C q u e, er 4A qu S e e, 4 B at C tle, hi C 4 c C ol o. ago Sp , 5 A r Bu ing rli s, 5 ng B to H n, 6 el en A a D , 6B u Fa l u t ir b h, an 7A ks ,8 A 0 H M ia Energy Savings (million Btu/yr) Reduced hood flow plus DCV on servery, carryout 45% 350 Figure 10. Annual energy savings for each ECM 28 Energy and Water Conservation Design Requirements for SRM Projects Figure 11. Various canopy hoods for cooking equipment (source, ASHRAE Standard 154). a. b. c. d. Figure 12. Example best-design practices within exhaust system design and specifications. 29