DFAC PRESCRIPTIVE TECHNOLOGY SOLUTION SETS List of Tables

advertisement

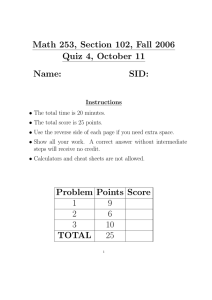

DFAC PRESCRIPTIVE TECHNOLOGY SOLUTION SETS Alexander Zhivov, Ph.D., Dale Herron and Richard Liesen, Ph.D. USACE Engineer Research and Development Center Michael Deru, Ph.D. National Renewable Energy Lab List of Tables Tables 1 DFAC Climate Zone 1A Prescriptive Solution Table......................................................................................... 2 2 DFAC Climate Zone 2A and 2B Prescriptive Solution Table ........................................................................... 3 3 DFAC Climate Zone 3A and 3B Prescriptive Solution Table ........................................................................... 4 4 DFAC Climate Zone 3C Prescriptive Solution Table......................................................................................... 5 5 DFAC Climate Zone 4A, 4B, and 4C Prescriptive Solution Table ................................................................... 6 6 DFAC Climate Zone 5A and 5B Prescriptive Solution Table ........................................................................... 7 7 DFAC Climate Zone 6A and 6B Prescriptive Solution Table ........................................................................... 8 8 DFAC Climate Zone 7A Prescriptive Solution Table......................................................................................... 9 9 DFAC Climate Zone 8A Prescriptive Solution Table....................................................................................... 10 10 Characteristics of reflective roofing materials............................................................................................... 12 11 Lighting Power Density...................................................................................................................................... 13 12 Baseline-Ventilation Requirements ................................................................................................................. 13 13 Energy-Efficient Ventilation Requirements..................................................................................................... 13 The use of a climate specific Prescriptive Technology Solution Set listed in Tables 1 to 9 for DFAC facilities will result in an annual energy consumption less than or equal to the target energy budget figure shown in Attachment 2 for this facility type and climate zone, will meet life cycle cost effectiveness requirements, and will not require any calculations to demonstrate compliance with the EPACT 2005 30% better requirement utilizing the methodology described in ASHRAE 90.1 Appendix G. The actual energy consumption budget for each prescriptive solution/climate zone is shown in Attachment 2. Climate zone identification information for Army locations is also shown in Attachment 2. Energy and Water Conservation Design Requirements for SRM Projects Table 1. DFAC Climate Zone 1A Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-15ci U-0.0634 Attic and Other R-19 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-6.5ci U-0.1242 R-13 R-13 Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC Unheated Service Water Heating R-13 NR (4) NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts R-13 Wood Framed and Other Economizer Ventilation R-6.3ci. 0.1067 Steel Joist Infiltration Vertical Glazing R-13 F-1.020 R-7.5 for 12 in U-0.70 U-0.70 Uninsulated U-1.45 U-1.45 0.25 cfm/ft @ 75 Pa (5) < 20% U-1.22 0.25 < 20% U-1.22 0.25 None ≤4% U-1.90 0.27 NR ≤4% U-1.36 0.19 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 NR Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. NR Motorized Control NR See Table Below (7a) See Table Below (7b) Friction rate Sealing Location Insulation level Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) Uninsulated 0.4 cfm/ft2 @ 75 Pa 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 2 Energy and Water Conservation Design Requirements for SRM Projects Table 2. DFAC Climate Zone 2A and 2B Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-15ci U-0.0634 Attic and Other R-19 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-6.5ci U-0.1242 R-13 R-13 Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC Unheated Service Water Heating R-13 NR (4) NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts R-13 Wood Framed and Other Economizer Ventilation R-6.3ci. 0.1067 Steel Joist Infiltration Vertical Glazing R-13 F-1.020 R-7.5 for 12 in U-0.70 U-0.70 Uninsulated U-1.45 U-1.45 0.25 cfm/ft @ 75 Pa (5) < 20% U-1.22 0.25 < 20% U-1.22 0.25 None ≤4% U-1.90 0.34 NR ≤4% U-1.36 0.19 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 NR Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. NR Motorized Control NR See Table Below (7a) See Table Below (7b) Friction rate Sealing Location Insulation level Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) Uninsulated 0.4 cfm/ft2 @ 75 Pa 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 3 Energy and Water Conservation Design Requirements for SRM Projects Table 3. DFAC Climate Zone 3A and 3B Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-20ci U-0.0481 Attic and Other R-30 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-10 U-0.0847 R-13 R-13 + R-3.8ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC R-13 Wood Framed and Other Unheated R-13 NR (4) NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Economizer Ventilation R-10.4ci. 0.0739 Steel Joist Infiltration Vertical Glazing R-13 Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts Friction rate Sealing Location Insulation level Service Water Heating Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) F-0.86 R-15 for 24 in U-0.70 U-0.70 Uninsulated U-1.45 U-1.45 Uninsulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.57 0.37 < 20% U-0.57 0.37 None ≤4% U-1.30 0.34 NR ≤4% U-0.69 0.19 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 No - 3A; Yes - 3B Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. No - 3A; Yes - 3B Motorized Control NR See Table Below (7a) See Table Below (7b) 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 4 Energy and Water Conservation Design Requirements for SRM Projects Table 4. DFAC Climate Zone 3C Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-20ci U-0.0481 Attic and Other R-30 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-10 U-0.0847 R-13 R-13 + R-3.8ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC Unheated Service Water Heating R-13 NR (4) NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts R-13 Wood Framed and Other Economizer Ventilation R-10.4ci. 0.0739 Steel Joist Infiltration Vertical Glazing R-13 F-0.86 R-15 for 24 in U-0.70 U-0.70 Uninsulated U-1.45 U-1.45 0.25 cfm/ft @ 75 Pa (5) < 20% U-1.22 0.39 < 20% U-1.22 0.39 None ≤4% U-1.90 0.39 NR ≤4% U-0.69 0.19 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 Yes – 3C Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. Yes – 3C Motorized Control NR See Table Below (7a) See Table Below (7b) Friction rate Sealing Location Insulation level Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) Uninsulated 0.4 cfm/ft2 @ 75 Pa 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 5 Energy and Water Conservation Design Requirements for SRM Projects Table 5. DFAC Climate Zone 4A, 4B, and 4C Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-20ci U-0.0481 Attic and Other R-30 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-13 U-0.0676 R-13 R-13 + R-7.5ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC R-13 Wood Framed and Other Unheated R-13 F-0.520 NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Economizer Ventilation R-10.4ci. 0.0739 Steel Joist Infiltration Vertical Glazing R-13 + R-3.8ci Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts Friction rate Sealing Location Insulation level Service Water Heating Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) R-15.0 for 24 in. F-0.843 R-20.0 for 24 in. U-0.70 U-0.50 Insulated U-1.45 U-0.50 Insulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.57 0.39 < 20% U-0.42 0.39 None ≤4% U-1.30 0.34 NR ≤4% U-0.69 0.34 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 No - 4A; Yes - 4B & 4C Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. No - 4A; Yes - 4B & 4C Motorized Control NR See Table Below (7a) See Table Below (7b) 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 6 Energy and Water Conservation Design Requirements for SRM Projects Table 6. DFAC Climate Zone 5A and 5B Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-20ci U-0.0481 Attic and Other R-30 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-13 U-0.0676 R-13 + R-3.8ci R-13 + R-7.5ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC R-19 Wood Framed and Other Unheated R-19 F-0.520 NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Economizer Ventilation R-16.7ci. 0.0521 Steel Joist Infiltration Vertical Glazing R-13 + R-3.8ci Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts Friction rate Sealing Location Insulation level Service Water Heating Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) R-15.0 for 24 in. F-0.688 R-20.0 for 48 in. U-0.70 U-0.50 Insulated U-1.45 U-0.50 Insulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.57 0.39 < 20% U-0.42 0.39 None ≤4% U-1.10 0.62 NR ≤4% U-0.69 0.39 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 No - 5A; Yes - 5B Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. No - 5A; Yes - 5B Motorized Control NR See Table Below (7a) See Table Below (7b) 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 7 Energy and Water Conservation Design Requirements for SRM Projects Table 7. DFAC Climate Zone 6A and 6B Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-25ci U-0.0388 Attic and Other R-38 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-13 U-0.0676 R-13 + R-3.8ci R-13 + R-7.5ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC R-30 Wood Framed and Other Unheated R-30 F-0.510 NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Economizer Ventilation R-25.1ci. 0.0377 Steel Joist Infiltration Vertical Glazing R-13 + R-3.8ci Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts Friction rate Sealing Location Insulation level Service Water Heating Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) R-20.0 for 24 in. F-0.688 R-20.0 for 48 in. U-0.70 U-0.50 Insulated U-1.45 U-0.50 Insulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.57 0.39 < 20% U-0.42 0.39 None ≤4% U-0.87 0.58 NR ≤4% U-0.69 0.49 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 No - 6A; Yes - 6B Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. No - 6A; Yes - 6B Motorized Control NR See Table Below (7a) See Table Below (7b) 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 8 Energy and Water Conservation Design Requirements for SRM Projects Table 8. DFAC Climate Zone 7A Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-15 R-25ci U-0.0388 Attic and Other R-38 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-13 U-0.0676 R-13 + R-7.5ci R-13 + R-7.5ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC Unheated Service Water Heating R-30 F-0.510 NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts R-30 Wood Framed and Other Economizer Ventilation R-25.1ci. 0.0377 Steel Joist Infiltration Vertical Glazing R-13 + R-3.8ci R-25.0 for 48 in. U-0.70 U-0.50 Insulated U-1.45 U-0.50 Insulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.57 0.49 < 20% U-0.33 NR None ≤4% U-0.87 0.71 NR ≤4% U-0.69 0.64 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 NR Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. NR Motorized Control NR See Table Below (7a) See Table Below (7b) Friction rate Sealing Location Insulation level Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) R-20.0 for 24 in. F-0.671 0.08 in. w.c./100 feet Seal class B Interior only R-6 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 9 Energy and Water Conservation Design Requirements for SRM Projects Table 9. DFAC Climate Zone 8A Prescriptive Solution Table. Item Component Baseline (1) Recommendation Min R-Value (2) Assembly Max (2) Roof Insulation Entirely Above Deck R-20 R-25ci U-0.0388 Attic and Other R-38 Cool Roof for Low Slope & Light color all others Solar Reflectance (3) Mass Walls Steel Framed R-11.4 + R-3.0ci U-0.0391 R-13 + R-7.5ci R-13 + 18.8ci Wood Framed and Other Floors Over Unconditioned Space Slab-on-Grade Doors Mass Skylights (Dining and Servery) Interior Lighting HVAC Unheated Service Water Heating R-30 F-0.434 NR (4) Heated Swinging Non-Swinging Window to Wall Ratio (WWR) Thermal transmittance Solar heat gain coefficient (SHGC) South Overhangs Percent Roof Area Thermal transmittance Solar heat gain coefficient (SHGC) Lighting Power Density (LPD) Occupancy Controls Daylighting Controls Plug Load Lighting All Ballasts Air Conditioner < 135,000 Btu/h < 240,000 Btu/h < 760,000 Btu/h Gas Furnace Supply Air Fan Total Efficiency All equipment Outdoor Air Damper Demand Control Kitchen Exhaust Fans Ducts R-30 Wood Framed and Other Economizer Ventilation R-25.1ci. 0.0377 Steel Joist Infiltration Vertical Glazing R-13 + 19.5ci R-25.0 for 48 in. U-0.70 U-0.50 Insulated U-1.45 U-0.50 Insulated 0.4 cfm/ft2 @ 75 Pa 0.25 cfm/ft @ 75 Pa (5) < 20% U-0.46 NR < 20% U-0.33 NR None None NR NR NR None NR NR 2 See Lighting Power Table See Lighting Power Table Below (6) Manual On/Auto Off (all periodically occupied spaces) Yes – Dining and Servery Compact Fluorescent (CFL) with electronic ballast Electronic None 10.1 EER 9.5 EER 9.3 EER 80% Et 0.2 NR Motorized Control NR 12.0 EER 12.0 EER 10.8 EER 90% Et 0.45 Variable Speed pumps, fans, etc. NR Motorized Control NR See Table Below (7a) See Table Below (7b) Friction rate Sealing Location Insulation level Gas hot water storage Pipe Insulation(d < 1.5in. / d ≥ 1.5 in.) R-20.0 for 48 in. F-0.671 0.08 in. w.c./100 feet Seal class B Interior only R-8 (8) 80% Et 94% Et 1 in. / 1.5 in. (8) 10 Energy and Water Conservation Design Requirements for SRM Projects Notes: 1. Baseline requirements are from ANSI/ASHRAE/IESNA Standard 90.1-2004. 2. U-values and R-values for assemblies and their definitions, requirements, and determinations can be found in ANSI/ASHRAE/IESNA Standard 90.1-2007, Normative Appendix A. 3. Light colored and cool roofs: reflect and emit the sun's heat back to the sky instead of transferring it to the building below. "Coolness" is measured by two properties, solar reflectance and thermal emittance. Both properties are measured from 0 to 1 and the higher the value, the "cooler" the roof. A high reflectance keeps much of the sun’s energy from being absorbed, while a high thermal emittance radiates away any solar energy that is absorbed, allowing the roof to cool more rapidly. Cool roofs are typically white and have a smooth surface. Commercial roof products that qualify as cool roofs fall into three categories: single-ply, liquid-applied, and metal panels. The solar reflectance and thermal emittance property values represent initial conditions as determined by a laboratory accredited by the Cool Roof Rating Council. Cool roofs are cost effective over air-conditioned spaces for buildings located in climate zones 1 - 5. In these locations, a minimum of 75% of the entire roof surface not used for roof penetrations shall be covered with roofing products that comply with one or more of the following: Have a minimum initial SRI of 78 for a low-sloped roof (a slope less than or equal to 2:12) and a minimum initial SRI of 29 for a steep-sloped roof (a slope of more than 2:12). Comply with the criteria for the US EPA’s Energy Star Program Requirements for Roof Products – Eligibility Criteria. For industrial buildings with only heating and ventilation, cool roofs can improve the comfort conditions (and hence productivity) in the space. In order to be considered a cool roof, a solar reflectance of 0.67 when tested in accordance with ASTM C1549, ASTM E903, or ASTM E1918 and, in addition, a minimum thermal emittance of 0.75 when tested in accordance with ASTM C1371 or ASTM E408, or a minimum Solar Reflective Index of 78 when determined in accordance with the Solar Reflectance Index method in ASTM E1980 where standard white is SRI = 100 and standard black has SRI = 0. An SRI can be determined by the following equations: SRI = 123.97 – 141.35(x) + 9.655(x2) where x 20.797 0.603 , 9.5205 12.0 Where is the solar absorptance (= 1 – solar reflectance) and is the thermal emissivity, which were derived from ASTM E1980 assuming a medium wind speed and are listed in Table 10. Characteristics of reflective roofing materials.. 11 Energy and Water Conservation Design Requirements for SRM Projects Table 10. Characteristics of reflective roofing materials. Roofing Type Color New Solar Reflectance Aged Solar Reflectance New Thermal Emittance SRI (ASTM E1980 Roof Coatings White 0.70 – 0.85 0.50 –0.65 0.85 84 – 106 Roof Coatings Grey or Tan 0.70 0.50 0.85 84 Roof Coatings Terra Cotta or Brown 0.40 0.30 0.85 43 Roof Coatings Aluminized 0.50 0.40 0.50 42 Metal Paint Red 0.25 0.25 0.83 22 Metal Paint Terra Cotta 0.35 0.35 0.83 36 Metal Paint Bright Red 0.35 0.35 0.83 36 Metal Paint Beige/Off White 0.55 0.55 0.83 63 Metal Paint Tan 0.45 0.45 0.83 49 Metal Paint Dark Blue 0.25 0.25 0.83 22 Metal Paint Medium to Light Blue 0.32 0.32 0.83 32 Metal Paint Dark Brown 0.25 0.25 0.83 22 Metal Paint Medium to Light Brown 0.32 0.32 0.83 32 Metal Paint Dark Green 0.25 0.25 0.83 22 Metal Paint Medium to Light Green 0.32 0.32 0.83 32 Metal Paint White 0.65 0.65 0.83 77 Metal Paint Bright White 0.70 0.70 0.83 84 Metal Paint Black 0.25 0.25 0.83 22 Metal Paint Dark Grey 0.25 0.25 0.83 22 Metal Paint Medium to Light Grey 0.35 0.35 0.83 36 Metal Paint Pearlescent Colors 0.35 0.35 0.75 32 Galvalume Unpainted 0.65 0.55 0.05 45 Copper Metal Unpainted 0.85 0.18 0.03 89 Galvanized Steel Unpainted 0.40 0.20 0.50 26 EPDM Membrane Black 0.05 0.10 0.85 0 TPO Membrane White 0.80 0.60 0.85 99 TPO Membrane Grey 0.50 0.40 0.85 57 PVC Membrane White 0.80 0.60 0.85 99 57 PVC Membrane Grey 0.50 0.40 0.85 Asphalt Shingle Dark Color 0.10 0.10 0.85 4 Asphalt Shingle Light Color 0.25 0.25 0.85 23 Modified Bitumen Cap Sheet Dark Color 0.10 0.10 0.85 4 Modified Bitumen Cap Sheet Light Color 0.25 0.25 0.85 23 Modified Bitumen Cap Sheet White 0.50-0.60 0.40 – 0.45 0.85 57 - 71 4. NR means there is no requirement or recommendation for a component in this climate zone. 5. Increased building air tightness. Building air leakage (measured in cfm/ft2) is the average volume of air(measured in cubic feet per minute) that passes through a unit area of the building envelope (measured in square feet) when the building is maintained at a specified internal pressure (measured in Pascals). ASHRAE has proposed a building air tightness requirement of 0.4 cfm/ft2 @ 75 Pa as an addendum to Standard 90.1-2004. ASHRAE has also proposed an approach to complying with the new requirement with a pressurization test to show that the building leakage does not exceed 0.4 cfm/ft2 at 75 Pa. This air tightness requirement provides a number that can be used for the energy simulations and was assumed to be the baseline leakage rate. The air tightness requirement adopted by the U.S. Army for new construction is more stringent than the one proposed by ASHRAE and requires that the leakage rate must not exceed 0.25 cfm/ft2 at 75 Pa, and was assumed for the energy efficient building models. To convert the values used for building leakage tests at the pressure difference of 75Pa to the values which can be used to calculate required excessive outdoor air supply rates, the following equation can be used ΔQ = Q75 * (5/75)0.65 = 0.172 * Q75. The excessive airflow rate for the building complying with the new ASHRAE 90.1 Standard air leakage 12 Energy and Water Conservation Design Requirements for SRM Projects requirement is 0.069 cfm/ft2. Respective number for the building built to the Army model RFP requirement is 0.043cfm/ft2. 6. Lighting Power Density. Table 11 lists values for lighting power density. Table 11. Lighting Power Density. Baseline Zone W/ft 2 Efficient Model W W/ft 2 90.1-2004 Space Type W Dining 0.9 7,183 0.8 6,383 Storage/Receiving 0.8 2,098 0.8 2,098 Dining area Active Storage Dishwash 1.2 1,344 1.0 1,120 Food Preparation Kitchen 1.2 3,315 1.1 3,039 Food Preparation Servery 1.2 5,131 1.0 4,276 Food Preparation Entry/Circulation 1.3 4,277 1.0 3,290 Lobby Carryout 1.2 1,253 1.0 1,044 Food Preparation Office 1.1 1,588 0.9 1,300 Office Utility 1.5 1,580 1.0 1,053 Elec/Mech Total 27,759 23,596 7. Ventilation Requirements. Tables 12 and 13, respectively, list baseline and energy-efficient ventilation requirements. Table 12. Baseline-Ventilation Requirements. Zone Infiltration (cfm) 62.1-2004 Ventilation (cfm) Transfer Air (cfm) - 4,496 Maximum Outside Air (cfm) Dining 768 Storage/Receiving 248 315 77 784 Kitchen 190 1,934 Servery 294 1,145 Entry/Circulation 294 372 Carryout 131 93 Office 157 117 117 Utility 132 63 63 Dishwash 5,187 Exhaust Hood (cfm) 5,187 315 + 4,496 750 750 13,250 13,250 17,075 12,900* 2,100 2,100 372 Table 13. Energy-Efficient Ventilation Requirements. Zone Infiltration (cfm) 62.1-2004 Ventilation (cfm) Transfer Air (cfm) - 4,496 Maximum Outside Air (cfm) Dining 768 Storage/Receiving 248 315 77 784 Kitchen 190 1,934 Servery 294 1,145 Entry/Circulation 294 372 Carryout 131 93 Office 157 117 117 Utility 132 63 63 Dishwash 5,187 Exhaust Hood (cfm) 5,187 315 + 4,496 750 750 13,250 13,250 17,075 12,900* 2,100 2,100 372 8. Duct and pipe insulation, values are from the ASHRAE Advanced Energy Design Guide for Small Offices. 13