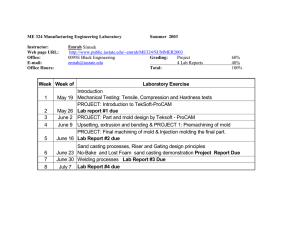

PROJECT #1: CNC MILLING OF A MOLD

advertisement

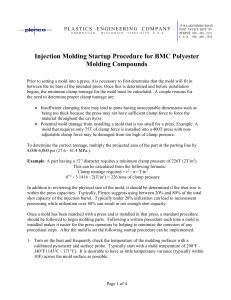

PROJECT #1: CNC MILLING OF A MOLD This project involves the practice of designing a mold for injection molding process to eventually produce a plastic part. The tools that will be used for the project are: TekSoft- ProCAM, CAD-CAM software Hitachi-Seiki CNC Milling Machine BOY Injection Molding Machine CMM (Coordinate Measuring Machine) The project constraints are as follows: The mold will be machined out of a 4”x 4”x 3/8” plate of Aluminum 6061 At least 1/2" of clearance is required from the edges of the mold. Maximum feature depth in the mold cannot exceed 1/8”. Text is not allowed in the mold design. Maximum simulated machining time allowed is 20 minutes. Use of at least 3 different cutting tools is required for the milling processes. WHAT IS REQUIRED IN THE REPORT: OBJECTIVE (5%) One sentence. INTRODUCTION (5%) A summary of the report. BACKGROUND (15%) A general overview of the processes involved in the project, e.g. CAD/CAM, CNC, Milling, injection molding etc. You are required to visit the Parks Library for this section of the report. PROCEDURE (25%) Begin with the constraints. List the steps involved at each phase of the project. Do not comment. RESULTS (35 %) State results of the procedures followed above. Remember, each phase of the project has a goal, which defines the results. The results are required to contain: list of layers, list of tools and depths of cut (designed and actual values), G-code, simulated machining time, actual machining time, visual characteristics of the mold and the part, injection molding process parameters and calculations. Do not comment or explain. DISCUSSION AND CONCLUSIONS (15%) Comment on your results and on the outcome of the projects. Draw conclusions and state them clearly. REFERENCES CONTRIBUTIONS PAGE By Emrah Simsek