10-11 SPEC WRITER NOTES: This specification addresses fire alarm systems

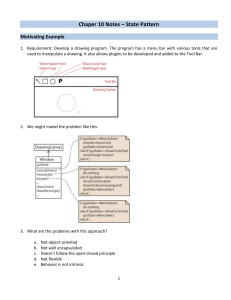

advertisement