02-01-15 SPEC WRITER NOTES: Delete between //----// if not 1.

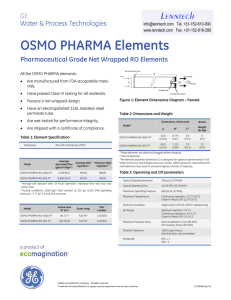

advertisement