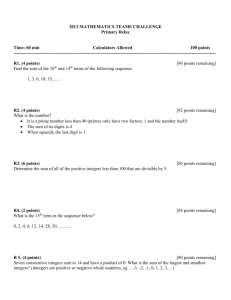

PACES

advertisement