Document 12074578

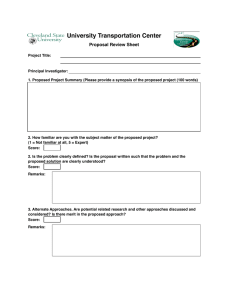

advertisement