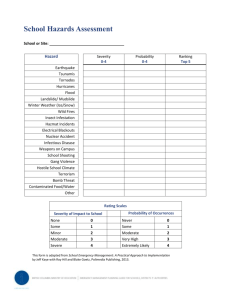

APPENDIX A Questionnaires

advertisement