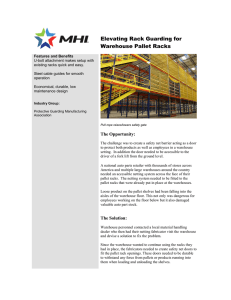

Seismic Considerations for Steel Storage Racks

advertisement