Document 12036312

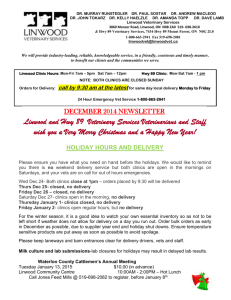

advertisement