9 Industry I CHAPTER

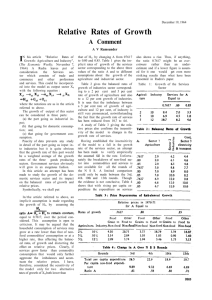

advertisement