ci* THE DESIGN OF A TESTING TRANSFORMER RESULTS OF TESTS

advertisement

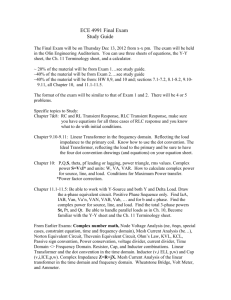

A THESIS THE DESIGN OF A TESTING TRANSFORMER SECONDARY VOLTAGE- 60,000. PRIMARY VOLTAGE- HO. CAPACITY 3 K.W. WITH DRAWINGS AND RESULTS OF TESTS ON DIELECTRIC STRENGTH OF VAR I OUS INSULATORS. 5. H. Graf. ci* Theory of the Transformer An alternating current transformer is an apparatus designed for the purpose of either raising or lowering the voltage of an alternating current circuit. In general it consists of two electrical circuits interlinked with a magnetic circuit, one called the primary into which the electrical energy is fed, and the ether called the secondary from which the electrical energy is taken. The operation of a transformer depends upon the law of induction; i,e, that a change in the rate of cutting lines of force by a conductor induces in the conductor an electro motive force which varies as the number of conductors cutting lines of force and the rate of cutting them. Since the current used in the transformer is alternating, the number of lines of force or the flux changes from zero to a positive maximum, through zero to a negative maximum and back to zero again, thus furnishing the necessary change in the number of lines of force out for the primary to induce an electro motive force in the secondary. Since the total flux of the magnetic circuit is dependent upon the number of turns of wire in the primary circuit, it follows that if the number of turns is not the same in the primary and secondary circuits, the electro motive forces in the t7o circuits will not be of the sane potential. This fact is Lade use of in the transformer and a ratio, called the ratio of transformation, is established between the primary and secondary circuits. If the secondary is of a higher potential than the primary, the transformer is called a step up transformer; if it is of a lower potential, the transformer is called a step down transformer. Step up transformers have their chief use in generating plants where, owing to the limitations of the generators a higher potential is needed for economical transmission. How- ever, for distribution, the potential must be reduced for practical reasons, hence step down transformers are employed to reduce the pressure so it may be safely used. These are the general uses of the transformer as applied to the distribution of electrical energy for commercial purposes. It has many special applications one of which is in testing the insulating properties of dielectrics. For this purpose it is un- excelled, as the extremely high voltages necessary for the breaking down of certain dielectrics render it almost impossible and quite impracticable for them to be generated at the dynamo. In making extensive tests, voltages as high as 500,000 are frequently used and in one case 1,000,000 has been reached. To develop these high voltages, the testing transformer is used. In principle it is the same as any other transformer, and differs in construction only in that to withstand the enormous differences of potential, it must be more perfectly insulated. Then also instead of coupling its secondary to a line, its terminals are brought out to binding pests much the same as an induction coil and are here connected to a suitable spark gauge. Since it is known ho,,- far a given voltage will cause a spark to pass in air, the length of the air gap forms a means of determining the voltage used on the dielectric. The tendency at present is toward increasing the voltages used in the transmission of electrical energy for power and light ing purposes. Thi is due to the fact that the line loss is less , for high voltages than for low ones since the current is less for a given power transmitted and the loss varies as the square of the current. To meet the increasing voltages, there is a demand for more perfect insulators to be used both in the line and at the machine. To gain any idea of the insulating value of a di electric when subjected to the constant strain of a high potential, it is necessary to subject it to a brief strain of much higher potential perhaps twice as high. For obtaining the necessary high pressure in making the tests the testing transformer is used. Design. The following is the deign of a typical testing transformer of 3 K.W. capacity, core type to step 110 volts up to 60,000. In this work Ep, will mean the impressed primary E.M.F. Bm, the maximum flux density; primary circuit; Tp, the number of turns in the t, the depth of the secondary coil in inches; al the length of the core limbs; limbs; b, the distance between the core e, and d, the dimension of the cross section of the cores which are to be square, hence o = d; diameter if the secondary wire. The known values if these are assumed as follows, Ep =110 volts; Tp = 82 turns; f 7 60 cycles. f, the frequency, and d, the Bm = 14,000 gausses; The secondary wire is to be No.35 hence from a wire table d = .01162 in. a, b, o, and t, are to be calculated. From "Sheldon's Alternating Current Machines", the necessary area of the core A, is found by the following equation.. A = 10 8 Ep 1.417Tf Tp Bra Substituting in this formula the values assumed and it becomes. 10 8 X 110 1.41-X 3.1416 X 82 X 14,000 = 36 sq. om. This gives us a core 6 cm. square or reducing to inches 2 3/8 in. The high flux density was taken because in making insulation tests, the secondary becomes practically short circuited and the high flux density causes a high leakage flux and a smaller lose f current. For an ordinary lighting or power transformer, the flux density for a 60 cycle current would not exceed 9,000 gausses. Working at a higher density lowers the efficiency some- what but this is a matter of no great importanoe in an instrument designed only for test purposes. It is intended in this instrument that the primary and secondary -coils be wound on the separate limbs of the core. The secondary will be the larger, hence the dimensions a, b, and t, will be derived from calculations based on the secondary coil only. Let the ratio of a to b, be as 1 to 1.5; and let 15/16 in. be allowed for clearance on each coil. Then it is evident that in order to assemble the transformer, b must equal 2(t 15/16). To determine t, if 11/16 in. be allowed at each end of the coils for insulation, and taking the ratio of transformation as 550, we have the expressioR, O4 550 Tp t= a - 1 3/8 Now since a = 1.5 b, and b = 2(t f 15/16) we may substin tute in the expressio for t, and it9.then becomes, t = 3(t 550 X 82 X .01162'" 15/16) - 1 3/8. = 1 7/8 inches. Substituting this value of t, in the expression for b, and we have b = 2(1 7/8 f 15/16) = 5 5/8 in. and a, which equals 1.5 b, equals 8 3/8 in. To obtain the volume of the iron in the core in cubic centimetres in order to oompute the hystersis loss we assume that 90% of the space occupied by the laminations is metal. This gives V = 2(a t b 2o) X o2 X 2.54 X .9 . Substituting the values found in the equation it becomes, V= 2(8 3/8 5 5/8 t 4 3/4) X 2 3/82 X 2.54 X .9 Solving this and we get for the vale of V 3,120 cu. am. To obtain the loss due to hystersis Ph, we apply Steinmetes Law and assume the constant n = .003. Ph = .003/107XfXVXBml°6 Substituting the values already found in this expression we have, Ph = .003/107 X 60 X 3,120 X 1400001 8 = 174 watts. To determine the loss due to Foucalt currents Pf, we make use of an empirical formula, Pf = 108V(y7X f X Bm) where y is the thickness of one plate. 2 This was taken as .01 in. Then Pf equals 10-8 X 3,120(.01 X 60 X 14,000)2 = 22.2 watts. Since the o pacity of this transformer is 3 K.W. then the full load primary current will be 3000/110 or 27.25 amperes, and the secondary current will be, disregarding losses 27.25/550 or .05 amperes. The primary is designed to be wound with 2 No.8 wires in 7arallel and its 82 turns will have a resistance of .03138 ohms. The secondary is to be wound with No.35 and it will have a resistance of 24,087 ohms. Letting Es, be the secondary E.H.F. Is, be the secondary current. Rp, be the primary resistance, and Rs, be the secondary resistance, we have the following equation to give the efficiency in per cent e, at any load. Es X Is e= (Fe X Is) t Ph t Pf f 102 Rs t T550 ITY2TRT-- Substituting the values in the equation we find the efficiency to be, 601000 X .05 e _§01000 X .05 t 174 t 22.2 rf (24,00027-4---tt tzra-rwmge Solving e equals .934 X 100 or 95.4 la Introduction to Drawings. The following drawings show the actual construction of the transformer and are intended for a working set. Plate A. shows the general construction of the ooze which is built up of soft electrical iron. It will be noticed that the core limbs are held together by wrought iron platew en either side through which pass stove bolts. The limbs are firmly clamped to the yokes by two steel bolts passing through angle irons which hold the yokes together. The connections between the yokes and limbs must be plane and smooth in order to make a perfect joint. Plata 7A. also shows the method of securing the transformer to the case cover by means of four holders. This is again shown in Plate D. plate B. shows the details of the core, the plates for holding the limbs together, the angle irons, and the necessary bolts. Plate C. is a general view of the coils. It willbe noticed that the secondary is to be wound in 36 sections and that the terminals are to be led through heavy rubber tubes to avoid short circuiting on the case. Plate D. is a general drawing showing dimensions of the case and the method of holding the transformer in the case. This plate also shows the sheet iron tank for containing transformer oil in which the transformer is submerged. This tank is to be an exact fit for the outer case Plate E. is ageneral view of the spark gauge and also shows tte details of the parts. It will be noticed that the gauge is mounted on convoluted. hard rubber standard . It is de- signed that the spark pass between needle points which must be kept sharp. The micrometer reads to .001 in thus giving very accurate results. Plate F. is an oblique projection of the complete transformer, and Plate G. is a diagram of the connections show ing the manner of connecting the transformer up to make a test. Drawings for- TESTING 300o (1' 6o Naffs Cycles Volts Sec. o,o o o TRANSFORMER Type Volts °AC. ELECTRICAL *-.-lialse,w1/4-44i41.,,LhavoKeisrge,,NAT44~,/,earit-e,f3,40 r °P:57 " Drill / /75: 7 -1-WJPc9s. some. the Both Mater-y(7i suitable o/her tubes fiber 4,1i/r/i //26-uloted be to Bolts thick mils /0 iron trah,5-forr7er laminated or made be to e Cor Ho/es . 11111111111 r 11111111MMM -1. Make ) W.I. HOLDER5. ( NMI , , 1.) _ .... :=-.... (.1103 . _ -. 0 I - i li=2 ==1 i--- i - 1 . IN ..... i.....m . . g==. ==1 0.. -...... . - a" 4 "Ns I- ^ icr r1/4--/g co Taps le Drill for v. countersunk heads Ism PLATES FOR LIMBS Two of each W. /. 5 / 3" 6 8 T 411q) 71 CO YOKE PLATES Four. W I PI CD JOINT PEGS Eight WI. AL SCREW FO Ten of these. L/M8,5 Stariotaraf. Couni Ne ads CLAMP/NG BOL/ Two. St. Standard 771 read. " Ord C)/Et-s 0 l` //-7 tor- 3t 60 ti SIN -ta Fiber /re Pop Pe bf Lin seed dory) /6 3 I rl I I 1 3 /z I I I T I, III Al it it I N , vi 3, h °le Fiber. The secondary co/7 is composed o There w,// b /,'ors Each sec 1-9- 70 0 tu of f./77/.2/r- e. Po/0 e r A42. E. th/ch of Ng 35 O.cc. vvi.r-e. /6 a foto/ of a//3. c /.7-, ode c.f./0 of two No. 8 wires. The 10,--/./77 ory ho.6.6/./7 iS the Sara e a The /or/n7 ary coil /5 not wo and of /./7 s /bs. of /11(2, 8 °cc, wire 5 Strap d The ,Secondary Sect/ohs ore to be insula With Pore briseco, 0./ oS wound, and then c fully baked 9" 3/6 m fit post used /lard rubber ;61. or fiber M -J_ n;l task. co gr 4 00/yd/7/zed iron. Te ICI -' 7* Fi /"'s tabN)2 1110111M111 im oi ,----/"Fiffthead 0m Stet./ Steel 0-0 PA 0. 00 (4) A- 01/. 31' 4- 1,4 4 LINE /2' 4-9 Case to be /77 aa'e of ?tic/trier sowed ook, RHEOS TA T 11 7 -' well seasoned, and /Yr, shed in /7 0' t1//Nond/es to be /co o / /shed kva/riut. Se cop. dory covered M N 6 ter- /77 ;1'7 /ate oi ono/ .screw s est for c o se to be C t-c./ 66,6er- by heavy t b /Qs, flathead brass wood Screws. I!* I / conk to he r ode oof i6 galvanized ee o a /7 o' of 31 z to fit case be A// e/ e c fr c so/der ed. connections must CAS E 3 K.VV TES-TING TRANS/T 0 C DepY. WEE, ca/e -3'. /' Mar 2/,b di) wog ,3);4+-4±4-+.4 Knurled head fl,lister--he ad ,/ C/a%77A3ing scre I6 OK, : #finitIMPRIVIIir*, d,o,iiIMUliinglinnaltahnnifijahltsUULIUrbiltal 1111 itgligkeL ma. "/////111/////, y el Br ass, ra ncia 1- cis f-far-d-r- \a\ I I il -.7. \ I=I I I Eai \ IC C=I 14 0\ z.0 I S PARK GAUGE KW TE T/NG T RA N,5" R. OA C Dept ofd' ca/e-6V:6' feb z3 b7 0 TEST I NG Type v.in -Set .E.511 TRANSFORME Ps,on ea Cy 4.2111 DE OA C ELECTRIC G 0 O S CONNECT I OM IV TEST/NG T RANS'R. OA C Dept of March ?2, 07 Method of Making Tests. the 2ample to be In making tests with the transformer, surfaces, which are cell tested is placed flat between two metallic. A water netted with the high tension side of the transformer. the purpose of regulating rheostat is put in the primary circuit for the impressed voltage. at a minimum distano 0 The needle points are then adjusted material under test, and apart, depending of course upon the passes between the the impressed voltage raised until a spark and the operThe air gap is then increased in length, points. down and the spark passes ation repeated until the sample breaks voltage is then through it instead of the air.. The break -down last position taken from a table or curve corresponding to the of the needle points. beyond the edges The sample should project considerably Owing to the surface leakage a of the compressing surfaces. of the surface of spark will pass over a much greater distance an insulator than it will in air. whether a given The apparatus may be used to determine impressed electro motive sample of insulation will withstand an The air gap is set so as to repforce without breaking down. voltage, and the sample subresent the value of the prescribed spark aorcias the jected to the pressure which maintains the In case of a break down the spark will cease. gap. be desired, Should the temperature of the dielectric be used so that the some suitable means of heating it should temperature may be measured. SPARKING DISTANCES IN AIR et we Cr? en sharp Ne ecile Points for- //, clie sinusoidal Voltages eco,77.-776,-,,,,,,<,,/ by /Ca/ Er,yin e ers. The Amer/car, 15 40 30 KILO 70 60 50 *00 90 80 1 , Kdo volts /o /5 0.225/u i 0.57 cm, 0.4-7 I. /9 0,727 Zo 1. 0 25 I.3 1 625 2.0 2.45 30 35 40 2.95 45 50 . 114° 3.55 DAr "Ca flC e Of /VC.' 017:7 °I $ .71C' e S 0 EA'N SQUARE -VOLTS, 5471/ARE R007' OF MEAN ., 18+ ' z,543.3 4./ 70 6,2 75 5:85" " 7/ //, 8 Crn, /9;9 h /49.9 If 212 244 /, 8.35 . .1/ 0 /0.75 27.3 /1.55 /2.95 /3.95 3 6.4- /40 . 4,65 /r7, 80 90 /co /20 /30 S./ 9.0 60 /So .9.6 /5.0 " h 304 32.9 38. / Results of Tests in The following results were obtained from tests made small transformer of about the manner described, and by means of a voltage of 10,000. 1 K.V.A. capacity, giving a maximum secondary Several sambles of each material were testeo and an computed for each average puncture voltage per mil thickness was Although lack of time and the small. capacity of the dielectric. tests, we belie,!e apparatus did not permit an extended series of that the results below are some practical value. Perrino, in his work "Electrical Conductors", says;"It the protection offered by is not possible to state distinctly that trials an insulation varies directly with its thickness, indeed, their involving the piercing of dielectrics seem to inJ'ioate that to the suare than to resisting power is proportional more nearly though in insulating wires the first power of their thickness; is unsafe to assume used for transmitting alternating currents it than the first that the resisting power increases more rapidly account of a general uncertainty conpower ofthe thickness on motive force to the cernin6 the relation of the maximum electro in the forms of average value on account of great variations different electro motive force curves generated by commercial machines". To give the break down voltage per mil has therefore been demed suficient. Trade Name. Break Down Voltage. Per Mil. Fiberoid. Remarks. Manufacturer. Color - Gray Wilmington Fibre Specialty Co. Wilmington, Del. 142 1 & 2. 188 1 & 2. 42 1 & 2. 129 1 & 2. nnnn tt White Fibre. Red Fibre. It Red Fibre. n 11 140 ft it If it 4. 74 Extra Flexible Micanite Cloth. ft IT From O.A.C. Stock. Oiled Linen. Extra Flexible Micanite Paper. II Partly 4. n Mica Insulator Co. Chicago, Ill. Ty it it It It ft it it It tt It II It n it It ft It It it it it n It ft It ft " " " " " it 132 tt Micanite Paper. ft 148 Empire Cloth No.5. 858 4. 925 4, 512 4. Empire Cloth No.7. Empire Cloth Nb.8. Empire Paper No.D. 870 Dark Amber Mica Brantford, Ont. North Carolina White Mica. Somewhat 3. 4 The Cawood Mica Co. Buffalo, N.Y. 1560 2. n 1290 'I n n n 2. 1. Absorbs moisture slightly. 3. Mechanically weak. 2. Fire resisting. 4. Combustible. The above tests were all made at ordinary room temperature. Cloth and Paper Some of the heavier grades of Empire were beyond the capacity of our transformer. All the material from the Cawood tested was from commercial samples, the mica North Carolina. Mica Co. was taken from mines in Ontario and Brantford, Ont. The first piece coming from Hughes' Mine near Shelby, N.C. and the second from the Hefner Mine near