In this issue Professor Peter Dunnill remembered The Automation Partnership

advertisement

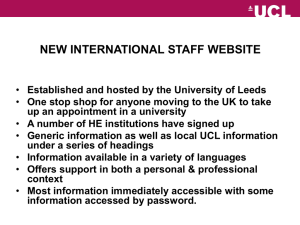

UCL ADVANCED CENTRE FOR Biochemical Engineering In this issue Professor Peter Dunnill remembered The Automation Partnership Economic Challenge Investment Fund New Vaccines MBI® Module IMRC Annual Briefing Future training needs ISSUE FOUR | FEBRUARY 2010 Contents Editorial Editorial 2 Foreword by Professor Nigel Titchener-Hooker Departmental news 3 Welcome to this fourth edition of BioProcessing Matters. UCL and the Advanced Centre for Biochemical Engineering have always driven research excellence, and this newsletter provides a snapshot of some of the bioprocess leadership activities currently being undertaken with industrial partners. This issue of BioProcessing Matters marks a significant event in bioprocessing globally. The passing away of Professor Peter Dunnill obe freng ficheme on 12 August 2009 has been met with much sadness expressed by individuals worldwide. Peter was an inspiration to us all, a true leader and motivator. He was proud of the Department and of what it had achieved. His charm, modesty, wit and, above all, his passion and generosity will endure. I hope that in time we can identify some appropriate actions to take in order to set in perpetuity a fitting testament to his rare skills and insight. We are all the better for having had the privilege to work with Peter and to benefit from the fruits of his labours. The reach of Peter’s efforts cannot be understated; they were truly global. The sense of loss is all the more acute given Peter’s front-line involvement with international issues such as pandemic flu, on which he spoke on BBC Radio 4 just before he passed away. Peter gave his total commitment to his work and to his colleagues; our challenge now is to celebrate his achievements and to build upon that legacy. In that spirit I note the latest Advanced Centre research event (24 September) was a fantastic success. A series of presentations which demonstrated the breadth of our research vision were given to a packed auditorium of industrialists and academics from across the UK. These events are powerful opportunities to network and to build relationships. It is particularly exciting to see how well new researchers become involved in this kind of high-level activity. The buzz is quite infectious! Finally, Peter had a number of quite diverse passions. One of which many are aware was his desire to see vaccine production gain the same degree of rigorous bioprocess attention as biopharmaceutical proteins. Against that backdrop I am delighted to be able to announce that in 2010 we will be adding a Vaccine Bioprocessing module to our list of post-experience MBI® modules. New MBI® Vaccines Module in development for 2010 8 The Automation Partnership Professor Peter Dunnill obe freng ficheme remembered 9 10 Innovative Manufacturing Research Centre (IMRC) Annual Briefing 12 MBI® course dates 2010–11 16 2 Departmental news Wellcome Trust and Merck create a joint venture to develop affordable vaccines for low-income countries. We are delighted that one of our distinguished alumni and Visiting Professor, Barry Buckland, has been a key player in establishing the India-based Hilleman Laboratories. Professor Buckland, who built a world-class Bioprocessing R&D Group in his two decades at Merck, is acting as a Consultant to the new joint venture. The Laboratories will operate on a not-for-profit basis and will extend the legacy of Maurice Hilleman, PhD (the creator of more than 30 vaccines) by developing new vaccines and optimising existing ones. A pump-priming investment of $130m over the next seven years will mean that a significant programme to reduce the burden of infectious diseases in low-income countries can be undertaken. Altaf Lal, PhD, has been appointed Chief Executive Officer, and says “If we are successful at building new partnerships and collaborations with governments, other companies and NGOs, I am confident that we will be successful in delivering vaccines to the people who need them.” This initiative is particularly timely as UCL Biochemical Engineering will be launching a new Vaccines module to its highly successful Masters-level Modular Training for the Bioprocess Industries (MBI®) Programme in 2010. For further information about the MBI® Programme, or the Vaccine module in particular, please contact Dr Karen Smith, Director of Bioprocess Leadership, at karen.smith@ucl.ac.uk or telephone (0)20 7679 4411. To read the UCL Biochemical Engineering Press Release see www.ucl.ac.uk/biochemeng/about/news Knowledge Transfer Masterclass On 22 October Professor Nigel Titchener-Hooker and Professor Gary Lye delivered a one-hour Masterclass around UCL Biochemical Engineering’s Knowledge Exchange Continuum to a ‘standing room only’ audience composed of high-level government, academic and industry delegates at the Public Service Events Biotech 2009 – The Future Knowledge Economy at Central Hall, Westminster, London. Their key messages were: • The fast-moving bioprocess sector needs a plurality of knowledge transfer mechanisms to span graduate through to post-experience opportunities • UCL has a long-established track record of linking cutting-edge engineering science to real industrial application. This makes knowledge transfer both relevant and exciting. Also highlighted were several MBI® case-study examples of how companies use the Programme for continuing professional development and up-skilling of their workforce. Dr Karen Smith was on hand in the exhibition area to cover the dozens of enquiries made by interested visitors following the talk. 3 New Staff Dr Darren Nesbeth joined the staff of the Department in October 2009 as a Lecturer in Synthetic and Molecular Biology. He graduated in Molecular Biology at UCL before completing a PhD in Molecular Cell Biology at Imperial College. Darren’s postdoctoral posts included work on bioprocessing of lentiviral gene therapy vectors at King’s College London and Cambridge University, and biochemical studies of antigen presentation at Imperial College. Darren first joined the Department as a postdoctoral researcher within the Innovative Manufacturing Research Centre (IMRC) programme. His research interests include re-engineering mammalian and microbial cells to efficiently host novel biosynthetic pathways and for improved bioprocessing. Please feel free to contact him on 0207 679 7031 or at d.nesbeth@ucl.ac.uk. Mr Nicholas Cameron joined the department in September 2009 as Industrial Doctorate training Centre (IDTC) Manager. He has lived in London since 2005, having moved from Winchester where he graduated. In this new role, Nicholas will provide oversight of all EngD students from application to graduation as well as the Doctoral Training Centre’s academic leaders. As a member of the Department’s Doctoral Training Management Committee, he will also contribute to the promotion of the EngD course and its future development. Please feel free to contact him on 0207 679 2032 or at nicholas.cameron@ucl.ac.uk. Senior Executive Programme This is a time of change and uncertainty, but also one of great opportunities if we can identify and rise to the challenges we face. The qualities of leadership, sound business judgement and the ability to think innovatively are the essential prerequisites for success. Unparalleled linkages and partnerships between UCL and high-level industrialists and academics in other institutions prepared to share their vast wealth of knowledge and experience provide UCL with a unique proposition to engage senior executives in the bio industries. The VISION programme combines innovative management thinking with cuttingedge research to ensure your high flyers perform optimally. The programme comprises an intensive three-day core course supported by a series of business and technology briefings and workshops. Delegates select these shorter events following the core course in order to gain valuable insights into new areas and fresh approaches. The Programme will launch on 19 May 2010 and will be held on our Bloomsbury Campus in the heart of London. An impressive array of experts including Dr Neil Weir (Senior Vice-President, Global Research, UCB), Prof. John Birch (Chief Scientific Officer, Lonza Biologics), Dr Steve Arlington (Partner and Leader of Pharmaceutical & Life Sciences Advisory, PriceWaterhouseCoopers) and Dr Aileen Allsop (Vice President for Science Policy, R&D, AstraZeneca) will join our staff delivering sectorspecific case studies and workshop facilitation. If you are interested in attending, please contact Dr Karen Smith, Director of Bioprocess Leadership at karen.smith@ucl.ac.uk or telephone (0)20 7679 4411. 4 UCL Department of Biochemical Engineering This is a time of change and uncertainty, but also one of great opportunities if we can identify and rise to the challenges we face. The qualities of leadership, sound business judgement and the ability to think innovatively are the essential pre-requisites for success. UCL Biochemical Engineering has an international reputation for its research and teaching. Unparalleled lin kages and partnerships with high level industrialists and academics in other ins titutions prepared to share their vast wealth of knowledge and experience, pro vides UCL with a unique proposition to engage senior executives in the bio ind ustries. The VISION programme combines inn ovative management thinking with cutting edge research to ensure you r high flyers perform optimally. The programme comprises of an intensive thr ee day core course supported by a series of business and technology briefin gs and workshops. Delegates select these shorter events following the core course in order to gain valuable insights into new areas and fresh approaches. See www.ucl.ac.uk/biochemeng/vision for more information. We look for ward to welcoming you to UCL. Kind regards, Dr Karen Smith Director of Bioprocess Leadership iGEM silver medal success The first UCL team participating in the International Genetically Engineered Machine (iGEM) Competition (a world-renowned synthetic biology competition held yearly at MIT) was initiated by two very enthusiastic second-year biochemical engineers, Axel Nystrom and Anike Akinrinlade, in collaboration with one equally motivated second year biochemistry student, Xiang Chen. They were supported in their efforts by several members of staff from the Department, including Prof. Nigel Titchener-Hooker, Dr Eli Keshavarz-Moore, Dr Darren Nesbeth and Dr Karen Smith, and by Prof John Ward from the Department of Structural and Molecular Biology. Competing against over 110 teams, this small band of three (naming themselves ‘Stress Busters’) had to hold their own against a range of teams from across the globe, all comprising around ten to twenty members. Undeterred, they came away triumphant with a silver medal. They are hoping to have set the first stone in building a truly multidisciplinary team from UCL for future years and we warmly congratulate them on their efforts. If you are interested in sponsoring the UCL iGEM team next year please let us know. A range of packages is available. Department’s HEFCE Economic Challenge Investment Fund (ECIF) successes As highlighted in our previous newsletter, UCL has unveiled a radical, £3.8m package of activity designed to prepare UCL students for entry into an unprecedentedly difficult employment market, and to support businesses during the economic downturn. A number of measures have been devised to provide extensive support to students graduating this summer: the first part of the package follows a successful bid to the Higher Education Funding Council for England’s ‘Economic Challenge Investment Fund’. Our Department’s activity revolves around providing support to graduates to help them access skills training in a wide range of biotechnology and pharmaceutical companies. It also facilitates access to MBI® modules for employees in companies whose posts may be at risk due to the recession. Amongst the first companies to make use of the scheme for their employees are GSK and the Bio Products Laboratory. One of our new graduates, Jai Patel, impressed GSK so much at his ECIF interview that they offered him a full-time permanent position. The graduates on the scheme not only benefit from working with companies for between ten and 50 weeks, but also gain access to our high-quality MBI® postexperience modules, and acquire the kind of bioprocessing and business skills that will be invaluable to them in their future careers. For further information about the scheme please contact Dr Karen Smith, Director of Bioprocess Leadership, at karen.smith@ucl.ac.uk or telephone (0)20 7679 4411. 7 Future Training Needs in Bioprocessing: IChemE Symposium and EFB Networking Meeting In November the Department hosted two meetings which addressed future training needs in bioprocessing. The first was organised by Prof Gary Lye and Glen Robinson of Sartorius Stedim Biotech on behalf of the UK Institution of Chemical Engineers. It attracted 56 delegates from across the UK and Europe. The focus of the meeting was on Disposable Bioprocessing, the range of disposable equipment now available and the possibilities for running whole processes based on disposable technologies. The training discussion focused on the needs of students from undergraduate to Masters and doctoral level and the balance of knowledge and practical skills required to better equip students for industry where the use of disposables is increasingly widespread. The outcomes of the discussion were useful in helping the Department understand how to embed disposable technologies in the curriculum. The second, a workshop on education and training for measurement, monitoring, modelling and control in biochemical engineering organised by the M3C working group of the European Section of Biochemical Engineering Science in the European Federation of Biotechnology was hosted by Prof. Nigel Titchener-Hooker. The aim of the workshop was to provide an update on the present status of the subject and to identify critical issues for the furthering of successful education and training according to the needs in industry and public sector. Academic leaders attended from DTU in Denmark, Bremen and Saarland Universities in Germany, Linköping University in Sweden and the University of Newcastle and UCL in the UK. While industrial context was provided by experts from, Umetrics of Sweden, Lonza Biologics in the UK and Novo-Nordisk, Denmark. The Department continually evaluates the training received by all students in order to keep the various degree programmes and short courses up to date. The Industrial Training Advisory Board (ITAB) meets annually to ensure the relevance of the training programmes to industry. If you would like to find out more about ITAB please contact Dr Karen Smith, Director of Bioprocess Leadership, at karen.smith@ucl.ac.uk or telephone (0)20 7679 4411. 7 New MBI Vaccines Module in development for 2010 ® Vaccines make headlines. From cervical cancer to pandemic influenza, it is vaccines that the world relies on for protection. The use of vaccines has already been well established, but twenty years ago vaccines remained the purview of national healthcare providers or government research. This was because the price of vaccines had to fall between Dr Tarit Mukhopadhyay a historic average of $1–3 a dose, which resulted in limited research budgets. Today however, both healthcare providers and individuals are willing to pay more per dose and consequently this has lead to a renaissance in vaccine research and development. A precedent has been set with vaccines such as Prevnar and Gardasil, which cost $50 per dose. Western healthcare providers are willing to spend more per capita on medical treatment. This makes these new vaccines a viable alternative and also attracts more investment. Indeed, the vaccine market is set to grow by 12% per annum. However, there are still challenges, especially in reducing the cost barrier so that vaccines are affordable for all. While this could include various stakeholders, it is less economically developed countries that have yet to benefit from this vaccine renaissance. Part of the cost can be countered through localised manufacture, but a skills base also needs to be developed. At UCL, we believe we have a role to play as a centre of learning and a responsibility to take leadership on issues of global healthcare. This is why the department of Biochemical Engineering is putting together a new MBI course on Vaccine Bioprocess Development. The purpose of this course is to cover a broad range of topics from technologies to intellectual property that will facilitate vaccine development. The course is envisaged to be a three day event. Day 1 begins with an overview of the different technologies that have been implemented into vaccines. It then moves onto upstream development and focuses on the Quality by Design issues related to vaccines. Day 2 starts with an insight into Design of Experiments, allowing delegates to put into practice the material they learnt on day 1. It is followed by a look into new expression systems and rounded off with an insight into disposables for vaccine development and their application into emergency vaccines, where the challenge is to provide doses in the shortest time possible. The final day will focus on downstream processing and regulation. 9 The MBI Training Programme is run by the Department and comprises a series of UCL-accredited short courses in bioprocessing, designed specifically for industrialists. They can be taken as standalong modules or can be combined for certificate, diploma or Masters qualifications. To date 1,000 modules have been taught to over 700 international delegates, and more than 200 companies have participated. Regulation is key to defining the product, but vaccines are unique; the product defines the process – which in turn defines the critical process parameters and quality attributes defined in the regulations. Delegates will be exposed to the interplay of process development and regulation using real life examples. Woven through the three days will be other issues such as assay and analytics development and intellectual property law. This course is envisaged to run in December 2010 and will be suitable to those who wish to increase their knowledge of vaccine development or who are part of strategic planning of projects. The course will be taught by a mixture of both academics and industrialist to provide a balance of both the theoretical with industrial case studies. Vaccines are an important component of the healthcare sector and we believe that this course will help to facilitate knowledge transfer through the research community. For further information about the module please contact Dr Tarit Mukhopadhyay at t.mukhopadhyay@ucl.ac.uk or telephone (0)20 7679 2762. The Automation Partnership The Automation Partnership (TAP), is a world leading supplier for the design and operation of automated systems for life sciences applications. The company provides platforms for use by the biopharmaceutical sector, for example the controlled growth of microbial and mammalian cell line variations to evaluate ways in which proteins may be prepared. With the IMRC Programme, TAP provides vision and expertise for how the new ultra scale-down methods may be addressed in an automated fashion so as to allow the study of wide ranges of bioprocessing conditions. They are also involved with understanding how best to interface the ultra scale-down tools with automated analytical data collection describing process performance. In October, TAP announced its Advanced Projects Group has successfully collaborated with Cellectricon, the Swedish provider of innovative screening solutions for drug discovery, to produce fully automated high throughput patch clamp equipment known as the Dynaflow®HT System. If you would like further information about this, please email Richard Wales at richard.wales@ automationpartnership.com. For further information about membership of the IMRC please email Prof Nigel TitchenerDynaflow®HT fully automated high throughput patch clamp system Hooker at nigelth@ucl.ac.uk. 10 Professor Peter Dunnill OBE FREng FIChemE remembered Professor Peter Dunnill, who has died aged 71, was a British pioneer of biochemical engineering, the discipline that studies the power of biological science to produce valuable material such as vaccines and protein therapeutics. As a vaccines expert, he frequently advised journalists on pandemics including avian and swine flu, and was still being consulted within two weeks of his death. Born in Harrow, he received a technical school education in Willesden, northwest London. A BSc in chemistry from University College London in 1961 was followed by a PhD in protein crystallography at the Royal Institution, which he completed in two years, working with Sir Lawrence Bragg and David Phillips (later Lord Phillips). Appointment at UCL as a lecturer in physical methods in the Department of Biology followed in 1964. Five years later, he moved to the Department of Chemical Engineering. A remarkable academic career ensued which began with studies on the large-scale isolation of enzymes and their deployment as industrial catalysts. In a partnership with Professor Malcolm Lilly FRS, Peter devised the basis for the commercial production of semi-synthetic penicillins. At one point, over 80% of the world’s production of this vital class of antibiotic used the technology. A further breakthrough was the first large-scale isolations of the key enzyme now used as the basis for all routine blood cholesterol tests. Peter and his team produced an analysis of the unit operations needed to manufacture bio – pharmaceuticals on a commercial basis. These studies provided the basis for a global industry now worth £30bn. Towards the end of the 1980s, Peter saw there was a need for pilot-scale facilities capable of processing recombinant materials and in which to verify the predictive models then being devised by his academic team. Successive provosts of UCL, Sir James Lighthill and Sir Derek Roberts, shared this vision. The outcome was the college’s Advanced Centre for Biochemical Engineering. Opened in 1991, this unique resource continues to enable researchers to tackle industrially relevant targets. Integral to the centre’s vision was the establishment of a wide network of collaborations, academic and industrial, where Peter’s capacity to grasp the main issues from both science and engineering perspectives proved crucial. British bioscience research strategy was shaped by input from Peter over three decades, especially in his role as a specialist on successive government inquiries (the Reece inquiry, 1985; the Blundell inquiry, 1988). Elected to the Biotechnology and Biological Sciences Research Council in 1994, he also served on the Office of Science and Technology’s foresight panel on health and life sciences and the 2002–03 Bioscience Innovation and Growth Team. Awarded a DSc in biochemical engineering by the University of London in 1978, Peter was made a Fellow of University College London in 1981. His work was recognised by the Royal Society of Chemistry, of which he became a Fellow in 1979, 11 and then by Fellowship of the Institution of Chemical Engineers in 1981, and in 1985 he was elected as a Fellow of the Royal Academy of Engineering. His work was recognised by the Institution of Chemical Engineers in 1995 with the presentation of the Donald medal and by the Biochemistry Society with the presentation of the Heatly Medal in 1998. He was also appointed OBE in 1999. Peter was passionate about global health issues, including the debate on swine flu. His contributions were always lucid and thought-provoking. A consummate communicator, he relished the challenges of explaining the importance of biochemical engineering and its relevance on a global scale. A chronic spinal problem severely incapacitated Peter: however, despite this he was a steadfastly positive individual. He had a deep love of music and at one time even re-imagined his research activities in terms of leitmotifs, after Wagner. His most constant source of pleasure, though, was his work. He will be missed for his insight, his generosity of spirit, charm and acerbic wit. (Written by Prof Nigel Titchener-Hooker; first published in The Guardian on 28 September 2009) 12 Innovative Manufacturing Research Centre (IMRC) Annual Briefing We held our 2009 IMRC Briefing on 24 September and were joined by a large group of industrialists from member companies that included Avecia, Intercell, TAP and Tecan. In the morning there were fascinating research presentations by students – • James Galman ‘Molecular engineering of transketolase and adventures in pharmaceutical synthesis’ • Bala Bangaru ‘Cell engineering for manufacturability; the use of ultra scale-down experimentation’ • Andrew Tait ‘Understanding the interface between cell culture and primary recovery: An ultra scale-down approach for early insight in the biopharmaceutical discovery stage ‘ • Naveraj Gill ‘Application of Microwell and DoE Technologies for the Creation of Therapeutic Fusion Protein Processes’ • Mike Hughson ‘Vaccine Bioprocessing and Microscale Technology’ • Arjun Dhanoya ‘The characterisation of plasmid DNA complexes for application in genetic immunisation’ • Adam Stonier ‘Rapid prediction of facility fit issues and risk hotspots in downstream processing ’ This session was followed by a lunchtime poster session presenting the IMRC related research work of our students. The Microwell Special Interest Group (SIG) took place in the afternoon and focused on filtration techniques that have been developed as part of the IMRC for the collection of bioprocess data using low material volumes and automation platforms. The title for the afternoon session was ‘The Micro Agenda – what are the limits?’. Dr Simyee Kong spoke on automated flux determination in depth and sterile filtration studies and Guijun Ma discussed work around a mimic of a large-scale diafiltration process using an ultra-scale-down rotating disc filter. There was a talk on filtration optimisation in bioprocess development and the Tecan representative gave a presentation on new developments in automation. This was followed by an open discussion and a demonstration of IMRC low-volume filtration techniques. An evening Reception with cheese and wine concluded a very interesting and informative day. We are planning our next briefing for September 2010. Please join us to hear about our latest research and to meet the students and staff involved. For more information, contact t.woods@ucl.ac.uk 13 Top: Tracy Hanlon, EPSRC. Middle: Paul Dalby with Nigel Allison (HPA) and Morrey Atkinson (Eli Lilly, Ireland) reviewing the posters. Bottom: Sa Ho, Pfizer, reviewing the posters. Top: Nigel Titchener-Hooker and John Liddell, Avecia Biologics, discussing the talks at lunch. Middle: Gary Lye presenting information on the IDTC. Bottom: Students discussing their posters and networking 15 Contacts Research Sponsors: Dr Karen Smith Director of Bioprocess Leadership +44 (0)20 7679 4411 karen.smith@ucl.ac.uk MBI®: Miss Liz Barrett MBI® Manager +44 (0)20 7679 1316 mbi-training@ucl.ac.uk IMRC in Bioprocessing and Industrial Doctoral Training Centre for Bioprocess Leadership (IDTC) Professor Nigel Titchener-Hooker +44 (0)20 7679 3796 nigelth@ucl.ac.uk BiCE and Engineering Doctorate in Bioprocess Leadership Professor Gary Lye +44 (0)20 7679 7942 g.lye@ucl.ac.uk Professor Chris Mason RegenMed +44 (0)20 7679 0140 chris.mason@ucl.ac.uk MBI® course dates 2010–11 Mammalian Cell Processes: 1 – 3 February 2010 Stem Cell and Regenerative Medicine Bioprocessing: 22 – 24 February 2010 Quality by Design for Effective Bioprocess Characterisation and Validation: 1 – 4 March 2010 Design of Experiments for Bioprocess Optimisation: 15 – 17 March 2010 Effective Biopharmaceutical Development & Manufacture: 10 – 12 May 2010 Bioprocess Design & Economic Evaluation: 7 – 10 June 2010 Bioprocess Facility Design: 21 – 24 June 2010 Principles of Fermentation Processes: 4 – 6 October 2010 Rapid Fermentation Process Design: From Development to Manufacture: 18 – 20 October 2010 Challenges & Opportunities in Biocatalysis: 1 – 3 November 2010 Primary Recovery: 15 – 18 November 2010 Chromatography: 29 November – 2 December 2010 Vaccines: 8 – 10 December 2010 Mammalian Cell Processes: 31 January – 2 February 2011 Stem Cell and Regenerative Medicine Bioprocessing: 21 – 23 February 2011 Quality by Design: 28 February – 3 March 2011 Design of Experiments for Bioprocess Optimisation: 14 – 16 March 2011 Effective Biopharmaceutical Development & Manufacture: 9 – 11 May 2011 Bioprocess Design & Economic Evaluation: 6 – 9 June 2011 Bioprocess Facility Design: 20 – 23 June 2011 For more information, email mbi-training@ucl.ac.uk Work with us The UCL Advanced Centre for Biochemical Engineering actively encourages and fosters long-term research partnerships between its academics and sponsors for mutual benefit. We facilitate interaction in a range of ways, such as sponsor visits, industrial advisory boards, Bioprocess Briefings, industrial placements for graduate students and the MBI® Programme. Over 60 industrial and academic experts contribute to our MBI® activities. If you would like further information, please contact the appropriate member of staff listed to the left. 16