The Effects of pH Variation on Whisker Growth on Tin

advertisement

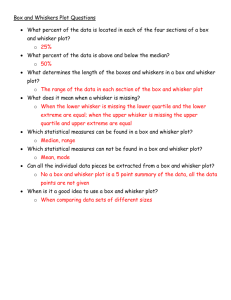

The Effects of pH Variation on Whisker Growth on Tin Plated Copper Jeffrey Wu Advisors: Uttara Sahaym, M. Grant Norton Materials Science and Engineering REU, Department of Mechanical and Materials Engineering Introduction: 1 2 The grain structure of the base layer of sample 1 is the roughest. It contains the highest number of pores among the three samples. The grain mutation smoothes out for sample 2. For sample 3, the base layer becomes a little more porous but remains less severe compared to sample 1. 3 Whisker Density: Increasing NaOH concentration From left to right, samples 1, 2, and 3 showing the Same matte surface finish Field Failure Caused by Tin Whisker Short 20 YEARS after System Fielded Whiskers Growing Inside of Hermetically Sealed Relays (Photos from http://nepp.nasa.gov/whisker/photos/pom/index.htm) Tin is an element commonly desired to plate on electrical components because of it’s corrosion resistance, conductivity, and its ease in soldering applications. Tin whiskers are single crystals that spontaneously grow from plated surface due to compressive stresses within the material, which can cause short circuits and failures in electronics. Traditionally lead has been used as an alloying element to suppress the growth of tin whiskers. However, the recent move to eliminate lead from consumer electronics has renewed interest in developing methods for minimizing whisker growths in tin. This research investigated the effects of changing the pH levels in the electroplating solution on tin whisker growths. Diagram of the electroplating apparatus Sample 1 Sample 2 Sample 3 Ideal Conditions Total NaOH added 0.97g 1.99g 3.03g 1.00g/2.00g/3.00g Bath Temperature 55°C 55°C 56°C 55°C Electrolyte Temperature 55°C 56°C 56°C 55°C Voltage 1.16V 1.14V 1.09V - Current 0.05A 0.05A 0.05A 0.05A Area ~1.2cm2 ~1.1cm2 ~1.05cm2 1cm2 Current Density 0.042 A/cm2 0.045 A/cm2 0.048 A/cm2 0.05 A/cm2 Weight Before Plating 1.625g 1.194g 1.215g - Weight After Plating 1.629g 1.196g 1.216g - Time Prior to Plating ~8s ~6s ~8s 0s Table of experimental conditions versus intended conditions Results: Surface Feature Density: Copper sample preparation: Plating solution setup: 28.5g of sodium tin(IV) oxide hydrate and 1.00g of sodium hydroxide were added to 200mL of deionized water for the first plating solution. It was then placed in a 1.5L water bath and stirred at a constant rate of 320rpm. Both, the water bath and plating solution, were heated and maintained at 55°C. For each subsequent sample, 1.00g of sodium was added to the plating solution. Plating process: The copper sample was attached to the power source as the cathode while a Sn anode of similar size was attached to the other end. Once the cathode and anode was dipped into the plating solution, the power source was kept at 0.05A for 3 minutes and 56 seconds. 2 mm Sample 1 Sample 2 2 mm Sample 3 The density of the crystals is highest in sample 1. The density decreases significantly for sample 2 but rises again for sample 3. Surface Feature Size: 500 nm Sample 1 500 nm 500 nm Sample 2 Sample 2 100 mm Sample 3 Conclusions: •At the lowest concentration of NaOH, the high density large, well-defined, pyramid-shaped crystals seem to correlate with the least amount of whisker growth. •When the NaOH concentration was raised to 10g/L, the smaller crystals and smoother base layer resulted in a higher density of whiskers, though the average lengths were relatively short. •At 15g/L of NaOH, the surface became less uniform with varying sizes of pyramid-shaped features and a rougher base layer than sample 2. This morphology resulted in the densest and longest whisker growths. Acknowledgements: Sample 3 Sample 1 has large, relatively uniform crystals. For sample 2, the crystals became noticeably smaller. For sample 3, the crystal sizes became uneven. Some crystals became larger while others remained relatively small. Base Layer Morphology: Special thanks to Hi-Rel Laboratories Spokane for their support SEM Observations: The three plated samples were observed under the scanning electron microscope within 24 hours of plating to observe the morphology of the Sn films. The samples were observed again after 16 days of aging for tin whisker growth. 2 mm Sample 1 100 mm On all three samples, whiskers generally grow larger and in higher densities on parts farther to the right side. Sample 1 has the least number of whiskers overall. The whiskers on sample 1 ranged anywhere between 16-75 microns in length and 1-3 microns in thickness. Sample 2 has a higher whisker count compared to sample 1, but the whiskers appear to be shorter. Whiskers on sample 2 range between 8-40 microns in length and 1-1.5 microns in thickness. Sample 3 appear to have the highest whisker growth concentrations compared to samples 1 and 2. Whiskers on sample 3 have been measured to be as long as 80 microns long and 1.6 microns thick. Procedures: Three copper samples were cut into 1cm x 2.54cm pieces. Each were grinded and polished with standard metallographic procedures up to 0.05 microns. Prior to plating, each sample was first cleaned in a sodium hydroxide solution, then in sulfuric acid. 100 mm 500 nm 500 nm Sample 1 Sample 2 500 nm Sample 3 This work was supported by the National Science Foundation’s REU program under grant number DMR-0755055