Oregon State University Utility Pole Research Cooperative 24th Annual Report September 30, 2004

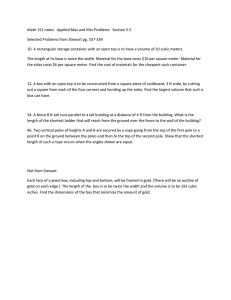

advertisement