Regional Workforce Development Center

advertisement

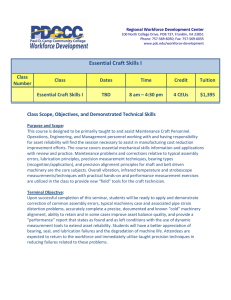

Regional Workforce Development Center 100 North College Drive, POB 737, Franklin, VA 23851 Phone: 757-569-6050; Fax: 757-569-6055 www.pdc.edu/workforce-development Essential Craft Skills II Class Number Class Dates Time Credit Tuition Essential Craft Skills II TBD TBD 4 CEUs $1,395 Class Scope, Objectives, and Demonstrated Technical Skills Building on the lessons taught in Essential Craft Skills I which created a precision approach to the required essentials of machine assembly and installation, Essential Craft Skills II, provides craft technicians with an analytical, application based approach to maintenance activities to better recognize and significantly reduce common machinery problems and failures. This session focuses on specific issues that surround the practices and components that commonly fail in plants - namely bearings, lubrication, couplings and sealing systems. This unique approach continues to raise the bar and help place the “craft” back in craftsman. The class begins with learning correct ways to disassemble failed machines to effectively and efficiently document failure symptoms and use those symptoms to assist in determining the root cause of failure. Having correctly identified the source of failure, this seminar moves forward to provide attendees with a real and working practical knowledge of various bearing applications, identification, removal/installation techniques and tips, and interpretation of correct fit charts with exercises. Focus then continues on the correct application of proven, essential lubrication best practice skills (selection, properties, types, housing, delivery systems), with a particular emphasis on the smaller “everyday” balance of plant machines that represent the majority of the asset base. In the power transmission section, attendees are introduced to the correct selection, installation, inspection and lubrication of commonly found couplings. The session finishes with an introduction to various shaft sealing systems allowing attendees to better recognize and field correct typical failure modes. Key elements of this seminar provide attendees with real, practical, and immediately applicable knowledge and, best of all, “hands on”, “performance based” class exercises. Where appropriate, these class exercises use “working” and “dynamically running” demonstrators. System “performance” measurements are completed in the classroom and provide technicians with an immediate feedback on the results and application value of applied techniques. These hands-on exercises comprise approximately 50% of the class. The seminar is designed as a continuation of knowledge for past ECS I attendees including craft technicians, maintenance and operations first line supervision, engineers, reliability team leaders, and any others who have responsibility to improve site reliability and manufacturing profitability.