2nd International Conference on Operations Research and Enterprise Systems (ICORES) 2013

advertisement

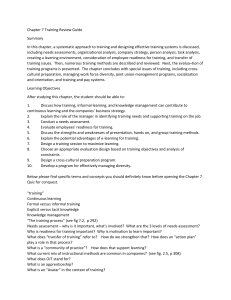

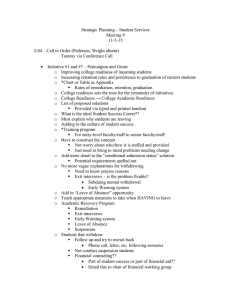

2nd International Conference on Operations Research and Enterprise Systems (ICORES) 2013 Barcelona, Spain ―Transforming a Complex, Global Organization: Operations Research and Management Innovation for the US Army‘s Materiel Enterprise‖ Greg H. Parlier, PhD, PE Colonel, US Army, Ret gparlier@knology.net 18 February 2013 1 Motivating Conditions • The changed geopolitical landscape resulting in the Army‘s transition to an expeditionary, globally deployable organization supported by a new force management concept (ARFORGEN); • The opportunity to consider, adapt, and extend integrating supply chain design concepts and management principles, and to apply ―advanced analytics‖ methods; • A clear understanding of the enabling potential offered by information technology (so-called ―IT solutions‖) and analytically-based decision support systems (DSS); • The DoD mandate for Performance Based Logistics (PBL), a major change in defense logistics management philosophy; • And, an obvious and compelling need driven by current fiscal realities, inevitable budget cuts, and the search for “efficiencies” . . . along with the ongoing quest for solvency in US public policy. A unique opportunity to develop and implement an ―analytical architecture,‖ in conjunction with a newly emerging management innovation paradigm, to guide Materiel Transformation toward a ―resources to readiness‖ framework 3 ―Formulas‖ 4 Transforming US Army Logistics: Project Phases What Happened? What Could Happen? A C B Concept Refinement 2002 Make it Happen! System Engineering & Development Technology Development 2003 Phase 2 Phase 3 • Segment the Logistics Structure & Processes for Analysis • Adapt Enterprise Supply Chain Framework for Integration • Identify "Readiness Production Function" • Develop "Mission Based Forecasting" • Validate "Readiness Based Sparing" • Incorporate Multi-Echelon Optimization & "Synchronized Retrograde Operations" • DDSN & LEWS • Provide COTS RBS Solutions for PSI • Develop Large-Scale MOD & SIM Capacity for SC Enterprise • Implement CILS Organizational Design • Strategic outreach & Research Partnerships for Continuous Improvement Task [$1.0M] O&S 2005 Phase 1 [~$200K] Production Expanded Market Opportunities [$2.2M] CILS Provides: • Product Support Integration • Supply Chain Optimization • Logistics System Readiness • AMSAA (RBS) • MCA Organization for Research and Analysis Acquisition Wholesale • SNL (RECAP) • IDA ( Reliability Design to Readiness) • UAH (OEM Supplier Analysis) • LMI (Peak Policy & ICAAPS) • PNNL (VLD) • USMC (TOC) • IDA Retail Unit Demand • LMI • AMSAA • PMs Reverse Logistics • RAND • LOGSA • SAIC • RAND (EDA) 5 Reasons for the Book (from Preface): 1. Resurrect traditional Operations Research (OR) for the US Army. 2. Apply ―advanced analytics‖ to our materiel enterprise challenges. 3. Link operational, technical, educational, scientific, and analytical communities. 4. Demonstrate ―Management Innovation as a Strategic Technology‖. 5. Document a case study for: analytically-driven, transformational change; a comprehensive, collaborative effort by many contributors. 6 Transforming US Army Supply Chains: Strategies for Management Innovation I. Project Overview 1. Background 2. The Immediate Problem 3. Current Logistics Structure 4. Supply Chain Concepts - Analytical Foundations for Improving Logistics System Effectiveness II. Multi-stage Analysis of Systemic Challenges 5. Readiness Production Stage 6. Operational Mission and Training Demand Stage 7. Retail Stage 8. Reverse Logistics Stage 9. Wholesale Stage 10. Acquisition Stage 11. Summary III. Multi-stage Integration for Efficiency, Resilience, and Effectiveness 12. Achieving Efficiency: An Integrated Multi-Echelon Inventory Solution 13. Designing for Resilience: Adaptive Logistics Network Concepts 14. Improving Effectiveness: Pushing the Logistics Performance Envelope IV. Design and Evaluation: An ―Analytical Architecture‖ to Guide Logistics Transformation 15. Multi-Stage Supply Chain Optimization 16. System Dynamics Modeling and Dynamic Strategic Planning 17. Operational and Organizational Risk Evaluation 18. Logistics System Readiness and Program Development 19. Accelerating Transformation: An ―Engine for Innovation‖ V. Management Concepts for Transformation 20. Organizational Redesign for Army Force Generation 21. Contributions of Information Systems Technology and Operations Research 22. Strategic Management Concepts for a Learning Organization 23. PBL and Capabilities Based Planning for an Expeditionary Army 24. Financial Management Challenges to ―Business Modernization‖ 25. Human Capital Investment for a Collaborative Organization 26. Final Thoughts 7 Transforming US Army Supply Chains: Strategies for Management Innovation ―Advanced Analytics‖ = Descriptive + Predictive + Prescriptive Analytics I. Project Overview 1. Background 2. The Immediate Problem 3. Current Logistics Structure 4. Supply Chain Concepts - Analytical Foundations for Improving Logistics System Effectiveness II. Multi-stage Analysis of Systemic Challenges 5. Readiness Production Stage 6. Operational Mission and Training Demand Stage 7. Retail Stage 8. Reverse Logistics Stage 9. Wholesale Stage 10. Acquisition Stage 11. Summary III. Multi-stage Integration for Efficiency, Resilience, and Effectiveness 12. Achieving Efficiency: An Integrated Multi-Echelon Inventory Solution 13. Designing for Resilience: Adaptive Logistics Network Concepts 14. Improving Effectiveness: Pushing the Logistics Performance Envelope IV. Design and Evaluation: An ―Analytical Architecture‖ to Guide Logistics Transformation 15. Multi-Stage Supply Chain Optimization 16. System Dynamics Modeling and Dynamic Strategic Planning 17. Operational and Organizational Risk Evaluation 18. Logistics System Readiness and Program Development 19. Accelerating Transformation: An ―Engine for Innovation‖ Descriptive Analytics: Where are we now? Prescriptive Analytics; Where do we want to go? Predictive Analytics: How can we get there? V. Management Concepts for Transformation 20. Organizational Redesign for Army Force Generation 21. Contributions of Information Systems Technology and Operations Research Managing Enterprise 22. Strategic Management Concepts for a Learning Organization 23. PBL and Capabilities Based Planning for an Expeditionary Army Transformation: 24. Financial Management Challenges to ―Business Modernization‖ What will it take? 25. Human Capital Investment for a Collaborative Organization 26. Final Thoughts 8 Transforming US Army Supply Chains: Strategies for Management Innovation Management Innovation as a Strategic Technology (MIST): OR + BI[MIS + DSS] + TSP[EfI + STAAMP] + IMS = MIST I. Project Overview 1. Background 2. The Immediate Problem 3. Current Logistics Structure 4. Supply Chain Concepts - Analytical Foundations for Improving Logistics System Effectiveness II. Multi-stage Analysis of Systemic Challenges 5. Readiness Production Stage 6. Operational Mission and Training Demand Stage 7. Retail Stage BI = Business Intelligence 8. Reverse Logistics Stage DSS = Decision Support Systems 9. Wholesale Stage 10. Acquisition Stage TSP = Transformational Strategic Planning 11. Summary Operations Research ―Advanced Analytics‖ EfI = Engine for Innovation STAAMP Strategic Architectures for III. Multi-stage Integration for Efficiency, Resilience,=and Effectiveness 12. Achieving Efficiency: An Integrated Multi-Echelon Inventory Solution Analysis, Management, and Planning 13. Designing for Resilience: Adaptive Logistics Network Concepts IMS Pushing = Integrated Management Science 14. Improving Effectiveness: the Logistics Performance Envelope TSP[EfI + STAAMP] BI[MIS + DSS] IMS IV. Design and Evaluation: An ―Analytical Architecture‖ to Guide Logistics Transformation 15. Multi-Stage Supply Chain Optimization 16. System Dynamics Modeling and Dynamic Strategic Planning 17. Operational and Organizational Risk Evaluation 18. Logistics System Readiness and Program Development 19. Accelerating Transformation: An ―Engine for Innovation‖ V. Management Concepts for Transformation 20. Organizational Redesign for Army Force Generation 21. Contributions of Information Systems Technology and Operations Research 22. Strategic Management Concepts for a Learning Organization 23. PBL and Capabilities Based Planning for an Expeditionary Army 24. Financial Management Challenges to ―Business Modernization‖ 25. Human Capital Investment for a Collaborative Organization 26. Final Thoughts 9 Part I: Project Overview 1. Background 2. The Immediate Problem 3. Current Logistics Structure 4. Supply Chain Concepts - Analytical Foundations for Improving Logistics System Effectiveness 10 The Immediate Problem: Circa 2002 3000 2800 Requirement 2600 2400 Funded 2200 UFR 200,000 2000 181,047 71% of NMCS Requisitions were for parts under $50 150,000 1800 112,946 1600 1400 100,000 1200 54,397 1000 38,202 800 50,000 600 11,212 12,042 2,491 400 200 -400 415 0 <$10 0 -200 2,491 97 98 99 00 01 02 <$50 <$100 <$500 <$1K <$5K <$10K <$50K >$50K 03 Cost of Part Requisitioned 11 Assessment: Circa 2002 • Investment is increasing, yet back orders are growing and UFRs are increasing • ―Workarounds‖ are increasing, readiness is slowly declining • Readiness reporting appears suspicious, lacks credibility • Systems are non-operational for relatively inexpensive parts ―Efficient Frontier‖ Ao ? $ Situation: Selected (Anonymous) Comments Following the Cold-War drawdown, as of late 2002 . . . ―All signs are bad‖ ―Huge disconnect between Log & Ops‖ ―Wholesale and retail are not integrated‖ ―There is growing fear that we do not have enough to ensure readiness; that fear is accompanied with perceptions of tremendous inefficiencies in our system‖ ―We could spend $100M on spares and see no readiness improvement, or we could spend $10M on spares (differently) and see it improve!‖ ―Why am I still throwing billions down this black hole called Spares?‖ ―We don‘t believe the aviation spares requirements numbers‖ ―The financial system is undermining our ability to do things smart‖ ―Our incentives are all in the wrong places…‖ But then . . . . ―The attacks of September, 11th, 2001, opened a gusher of spending that nearly doubled the base budget over the last decade, not counting the supplemental appropriations for the wars in Iraq and Afghanistan. . .‖ And now . . . . Situation: Selected (Anonymous) Comments And now (2012), a decade later . . . ―. . . today we face a very different set of American economic and fiscal realities . . . The gusher has been turned off and will stay off for a good period of time . . . The culture of endless money that has taken hold must be replaced by a culture of savings and restraint‖ ―[DoD must] . . . maximize value across the defense enterprise . . . [make] better use of information technology and inventory management‖ ―An era of blank-check defense spending is over . . .‖ Yet . . . ―. . . DoD does not do a world-class job with logistics by any measure . . . [there] is little cost visibility or performance accountability [and] weapon system readiness is not linked to supply chain responsibility.‖ ―DoD‘s supply chain system has remained stuck in a 20th Century model because of . . . resistance to change.‖ 14 Design of Enterprise Systems: Theory, Architecture, and Methods takes a system-theoretical perspective of the enterprise, and describes a systematic approach, called the enterprise design method, to design the enterprise. The enterprise design method demonstrates the principles, models, methods, and tools needed to design enterprise systems. Contact: Ronald Giachetti Professor, Systems Engineering Naval Postgraduate School Monterey, CA 93943 regiache@nps.edu Enterprise (Engineering) Systems • Some Definitions: – An emerging way to think about how to model, analyze, and design large-scale, complex, socio-technical systems. – An effort to better integrate engineering with management science, the social sciences, and the humanities. – A class of systems characterized by a high degree of technical complexity, social intricacy, and elaborate processes, aimed at fulfilling important functions in society. – Enterprise engineering is the body of knowledge, principles, and practices to design an enterprise. – An Enterprise is a complex, socio-technical system that comprises interdependent resources of people, information, and technology that must interact with each other and their environment in support of a common mission. An emerging field at the intersection of engineering, management, and the social sciences. 16 Enterprise (Engineering) Systems • Evolutionary ―Epochs‖: Structural elements and interactions – Great inventions and artifacts cause system attributes, functions, & – Complex systems behaviors. Architecture drives behavior, and governs systems performance and – Engineering systems value – both short and long term. • Characteristics: system “architecture” • Modeling and Analysis • Design ―levels‖ (project; enterprise; societal) • Systems Perspectives: – abstraction - decomposition for understanding – “viewing angles” - multidisciplinary views – perspectives - scale/scope, function, structure, temporality – properties - the “ilities”: quality; reliability; flexibility; adaptability; agility; modularity ….. sustainability …..affordability ….. “reversibility” ―Enterprise engineers specialize in integration: the process of making subsystems work together harmoniously in a way that optimizes the performance of the entire enterprise.‖ Ron Giachetti 17 II. Multi-stage Approach Analysis Systemic Part II: Multistage Analysis–of Systemic of Challenges Abstracting/Decomposition for Descriptive Analytics Challenges Acquisition Wholesale Retail Unit Demand Reverse Logistics 5. Readiness Production Stage 6. Operational Mission and Training Demand Stage 7. Retail Stage 8. Reverse Logistics Stage 9. Wholesale Stage 10. Acquisition Stage 11. Summary 18 Supply Chain Framework: Organization, Process, Supply Chain Framework and Information ―Views‖ of the Materiel Enterprise ReCap & ReSet Demand Inventory Vendors Orders to Vendors MATERIAL FLOWS Inventory Wholesale Inventory Retail Orders to Wholesale Inventory Unit Demand Orders to Retail INFORMATION FLOWS OMA Funding Available AWCF Payments to Vendors and Depots ReCap & ReSet Funding Obligation Authority OMA Funding FUNDING FLOWS 19 Supply Variability and Demand Uncertainty: Army Supply Chain Model Demand Uncertainty Supply Sources of Variability Acquisition Stage Wholesale Stage • Supply Depots • OEM‘s • SSAs • Repair Depots • Suppliers Unit Stage Retail Stage ―Readiness Production‖ • ASLs • OEM‘s • Training • Operations • Retrograde Operations Reverse Logistics Stage σ2 = LσD2+ D2σL2 …the ―bullwhip effect‖ qk Lk Suppliers Demand Stage q2 L2 q1 L1 Wholesale Retail q0 = D Unit Customer 25 s2 (qk) s2 (D) ―Decentralized ‖―Centralized ‖ 20 15 10 5 0 0 1 2 3 4 5 K = # of stages Summary of Systemic Challenges: Identifying Fundamental Cause-Effect Relationships To summarize generally, these causal disorders and their respective effects include: (1) lack of an aviation readiness production function which induces both uncertainty and variability at the point of consumption in the supply chain resulting in inappropriate planning, improper budgeting, and inadequate management to achieve readiness objectives; (2) limited understanding of mission-based, operational demands and associated spares consumption patterns which contribute to poor operational and tactical support planning and cost-ineffective retail stock policy; (3) failure to optimize retail stock policy to achieve cost-efficient readiness (customer) objectives which results in inefficient procurement and reduced readiness; (4) failure to proactively synchronize and manage reverse logistics which contributes significantly to increased DLR RO, excess inventory, increased delay times (order fulfillment), and reduced readiness while simultaneously precluding the enormous potential benefits of a synchronized, closed-loop supply chain for DLRs; (5) inability to ―see‖ – and to adapt to and anticipate changes in – actual customer demand, causing inefficient procurement actions within an unresponsive wholesale stage characterized by abysmal demand plan forecast accuracy thereby precluding enterprise-wide ―cost-wise readiness‖; (6) limited visibility into and management control over disjointed and disconnected OEM and key supplier procurement programs which are vulnerable to boom and bust cycles with extremely long lead times, high price volatility for aerospace steels and alloys, and increasing business risk to crucial, unique vendors in the industrial base resulting in diminishing manufacturing sources of materiel supplies, and growing obsolescence challenges for aging aircraft fleets; (7) independently operating, uncoordinated and unsynchronized stages within the supply chain creating pernicious ―bullwhip‖ effects including large RO, long lead times, and declining readiness; (8) fragmented data processes and inappropriate supply chain MOEs focusing on interface metrics which mask the effects of efficient and effective alternatives, and further preclude an ability to determine ―readiness return on net assets‖ or to relate resource investment levels to readiness outcomes; (9) lack of central supply chain management and supporting analytical capacity results in multi-agency, consensusdriven, bureaucratic workarounds hindered by lack of an Army supply chain management science and an enabling ―analytical architecture‖ to guide Logistics Transformation; and (10) lack of an ―engine for innovation‖ to accelerate then sustain continual improvement for a learning organization. 21 Officer ORSA (FA49) Strength in AMC History of FA49 Authorizations in AMC 60 COL LTC MAJ CPT 50 Authorizations 40 30 20 10 0 FY88 FY89 FY90 FY91 FY92 FY93 FY94 FY95 FY96 FY97 FY98 FY99 FY00 FY01 FY02 FY03 COL 5 5 3 3 3 2 2 2 2 1 1 1 0 0 0 0 LTC 9 9 6 6 6 5 5 3 3 1 2 1 0 0 0 0 MAJ 12 15 11 11 11 14 8 5 6 2 1 2 0 0 0 0 CPT 25 24 28 28 28 7 4 4 4 0 0 0 0 0 0 0 Analyzing Root Causes and Prescribing Innovation Catalysts Across the Supply ChainTowards Working ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (1) lack of an aviation readiness production function which induces both uncertainty and variability at the point of consumption in the supply chain resulting in inappropriate planning, improper budgeting, and inadequate management to achieve readiness objectives; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 23 ―Production Function‖: Components of Readiness Demand Requirements Supply Availability Weapon System Reliability • Deployment Missions (DEPTEMPO) - Patterns of Operation Duration Profile - Environmental Conditions and Locations MTBF - NMCS Supply Support Capability MLDT - NMCM Operational Availability (Ao) [ER] MTTR Personnel Manning and Skill Levels Training Resources (OPTEMPO $) [AS] • Training Requirements (OPTEMPO) - MC - FMC - PMC [TS] Readiness – related Measures / Metrics [ER] – Equipment Readiness (Ao) • FMC • NMCS • MC (PMC) • NMCM [AS] – Assigned Strength [TS] – Trained Strength Cost of Part vs Percent of Not Mission Capable Supply/ Anticipated Not Mission Capable Supply Requisitions (All Army LIF Records Nov00 to Oct01) Percent 50 NMCS 45 43.6 Low $ Parts Are Causing Army Weapon Systems to Be NMC 40 35 27.2 30 25 20 15 13.1 9.2 10 2.7 5 2.9 0.6 0.6 0.1 0 $ <10 <50 <100 <500 <1K <5K <10K <50K >50K 80% of NMCS/ANMCS Requisitions at Wholesale Were for Items <$100 Source: AMSAA Innovation Catalyst: Analyzing the Readiness Equation Innovation Catalyst: Analyzing Readiness Equation and Measuring True ―Customer the Demand‖ AO = Labor = Uptime Total Time MTBF MTBF + MTTR + MLDT Where 90% MC 80% MC MTBF = Mean Time Between Failures (Reliability) MTTR = Mean Time To Repair (Maintainability) MLDT = Mean Logistics Delay Time (Supportability) Research Goals: - Define and empirically measure the ―readiness equation‖ for Ao - Determine readiness ―driver‖ marginal values, and evaluate contributions and costs for potential solutions. Capital Extract from research results: - The longer the delay, the more likely a workaround . . .15% of deadline requisitions for wholesale backorders were satisfied by workarounds. - ―Labor‖ (MMH) increasingly substituting for ―Capital‖ . . . If workarounds were eliminated, readiness would decline by 33%. - ―Consumption‖ data is not systematically collected by current MIS 26 Center for Systems Reliability Readiness & Sustainment Department Sandia National Laboratories (SNL) Albuquerque, NM 87185 Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy under contract DE-AC04-94AL85000. Integration Opportunity: Connecting CBM to the Supply Chain ―Connecting‖ CBM to the Supply Chain: A Conceptual View ACQUISITION WHOLESALE RETAIL UNIT DEMAND RETROGRADE GCSS-A CBM Data Warehouse PLM+ LMP In Theater Maintenance Platform PMs Usage & Operations Condition & Health Environment Prognostics Logistics Req’s Failure Analysis Regime Recog Fleet Managers IMMC Historical Supply Chain Data LOGSA OEMs 29 ―Connecting‖ CBM to the Supply Chain: A Mathematical View Reactive Repair Proactive Replacement Reactive Repair vs. Proactive Replacement Downtime MTBF Xf Xf t2 W A OST1 MTBR Xr MLDT t3 Down time MTBR MTTR OST MTTR t1 R OST2 t3 A U OST3 ? t2 W OST1 t1 R OST2 U Xr 30 Volatility the Army Multi-Stage Logistics Model Supply in Chain Improvement Opportunities: Reducing Demand Uncertainty in the Army Supply Chain Model Demand Uncertainty Supply Sources of Variability Acquisition Stage • OEM‘s • Suppliers Wholesale Stage • Supply Depots • Repair Depots • OEM‘s Retail Stage • SSAs • ASLs Reverse Logistics Stage • Retrograde Operations Unit Stage Demand Stage ―Readiness Production‖ • Training • Combat Missions • Stability Operations How can we drive down demand? 1. Improve reliability to extend useful life 2. Use CBM to create demand signal 3. Improve demand forecast accuracy Connect CBM to the supply chain – Anticipatory Demand 31 Connecting CBM to the Supply Chain: A Six Month Pilot Project Purpose: Analyze and link existing Army logistics and CBM datasets to a new forecasting method/model to better predict DLR replacement Benefits: • Improves Forecast Accuracy - Enables ―right-sizing‖ component inventory levels • Reduces Operation & Support Costs and Facilitates Efficiencies - Improve visibility of the reliability state of aircraft components, giving advance warning of demand - Reduces inventory footprint and operating costs versus personnel • Increases Component Availability/Readiness Levels - Reduction in NMCS results in improved readiness and cost avoidance (premium purchases, shipping, etc.) Connecting CBM to the Supply Chain Project Process Develop Prognostic Simulation Project/Process Flow: Analyze Existing, Actual Data Validate Algorithm Baseline Metrics DA Form DSC 2410 Develop Predictive Algorithm ASAP Data RIMFIRE LMP SSA Inventory Prognostic Simulation Tool Failure Rate Curve: Component Health Connecting CBM to the Supply Chain Prognostic Algorithms Engineering and Logistics Components • Reliability State Algorithms – Predicting Supply Chain Performance – Velocity of Supply (VoS) – Based on supply chain history Supply Response • Logistics Side Algorithm E (T f ± d f ) E (Td ± dd ) Goal: Component arrives before actual failure Component Condition – Identifying current reliability state (Rvs) to predict time to failure – Predicting Failures (DSC data) – Associating to maintenance events (2410 data) Time Connecting CBM to the Supply Chain Remaining Useful Life CBM “Alert”(Ta) (Ta) Prognostic Normal Distribution Component Replacement (T (Tr) r) density From Prognostic Algorithm = Time to Replacement Failure Rate Curve 1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 λ0.1 0 Early demand signal can drive down retail stockage Available ost Tr Ta Tf Tr – Ta > OST Time -10 -8 -6 -4 -2 0 Reliability improvements & Time on Wing Extensions x 2 4 6 Connecting CBM to the Supply Chain CBM Prognostics Simulation Model - Initial Results Expected Results Based on Improved Predictive Ordering # of Times an Aircraft was Down for More Than One Day Days Ordered Early (compared to historical requisition times) Inventory Reduction 0% 2% 5% 10% 15% 20% 25% 0 110.7 130.1 150.7 196.4 230.7 256.2 287.4 2 4 6 8 77.4 99.6 120.5 155.6 196.4 232.8 265.4 48.1 66.3 81.9 113.4 166.4 201.8 244.1 34.9 45.8 52.0 89.2 134.8 180.2 223.7 22.8 27.1 36.6 61.1 105.4 147.7 180.6 12 7.4 12.0 13.1 27.3 51.9 78.7 128.0 16 1.6 2.9 5.6 9.2 22.3 44.9 59.2 Actual Inventory Level 37 36 35 33 31 29 27 Inventory Cost Savings $0 $51,801 $103,602 $207,204 $310,806 $414,408 $518,010 Calibrated using actual 2410 data for AH-64D Nose Gear Box • 2 Variables, 7 levels each, 49 options, 90 simulation runs per option = 4410 total runs Analyzing Root Causes and Prescribing Innovation Working Catalysts Across the Supply Chain Towards ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (2) limited understanding of mission-based, operational demands and associated spares consumption patterns which contribute to poor operational and tactical support planning and cost-ineffective retail stock policy; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 37 Continuous front Front Continuous Analyzing Operational Forms and Empirical Patterns Main attack Secondary attack Effects-based operational forms: Fix Fix 3 observed force-on-force forms Secondary attack Main attack Continuous fronts Disruptions Fix Disruption Disruption (high-order)(high-order) Disintegrations Fix Main attack Fix + Stability operations Main attack Fix Fix Secondary attack Disintegration Disintegration Main attack Fix Fix Main attack Fix Secondary attack Fix Fix Fix Secondary attack Main attack Fix P A G E 38 Stability Opn STRATIFIED SAMPLING POPULATION OF SIZE N DIVIDED INTO K STRATA RANDOM SAMPLING: x Pˆ RSM n STRATIFIED SAMPLING: xk Pk n k 1 THEN: k N k Pk i 1 Pˆ STRAT N 1 USUALLY: Var ˆ STRAT VarPOP Var ˆ RSM Innovation Catalyst: Mission-Based Forecasting (MBF) Innovation Catalyst: Mission Based Forecasting (MBF) Research Goal: Our major hypothesis states: ―If empirically-derived Class IX usage patterns, profiles and/or trends can be associated with various operational mission types and environmental conditions, then operational planning, demand forecasting, and budget requirements can be significantly improved to support a capabilities based force‖. 111 84 111 CONUS vs IraqStab CONUS vs IraqMCO 2833 2833 88% Note: original Views (2005 data) 29% IraqMCO CONUS AH-64D AH-64D 73% 12% 71% 6 5 4 3 2 1 0 1.0 87 27% 59% IraqStab CONUS 6 5 4.4 x CONUS 3.9 x CONUS 4 3 2 Ratios 1 RatiosofofDemands: Demands:Common CommonParts Parts 0 41% 1.0 40 Note: New (2006) data Note: New (2006) data Note: New (2006) data Tested MBF Method Using Real Data from Four Operational Cases Operation (OpTempo) Duration AH-64D UH-60 Case 1 Stability Ops (high threat ) 6 months 24 tails 22 tails Case 2 Stability Ops (mid-level) 6 months 79 tails 10 tails Case 3 Case 4 Stability Ops (mid-level) 12 months 104 tails Garrison (Training, CONUS) 12 months 54 tails 40 tails MBF compared to MBF uses maintenance data A B C D Current forecast methods use requisition data Comparing Forecast Approaches: Accuracy versus over- and under-forecast Accurate Found Error Actual NSNs Used (over-forecast) Error (under-forecast) Forecasted NSNs The Analysis addresses two perspectives Actual Forecast Part Analysis Quantity Analysis Errors Found (over-forecast) Forecasted Quantity Errors (under-forecast) Forecasted Quantity Actual Quantity Actual Quantity NSN lines [―breadth‖] Cost Quantity [―depth‖] 45 AH-64D Parts Count Forecast (Breadth of NSNs): MBF Compared to(Lines) Current Methods Phase 2 Membership - Case 3 JLAT (3 hr) Case 3, Stability Ops without (mid-level threat), 12 months, 104 tails 2,500 MBF reduces part over-forecast, and under-forecast & improves forecast part-accuracy 2,000 Part Count % ―Found‖ out of total forecast parts (breadth) 1,500 Over-forecast Found (correctly forecast) Under-forecast 1,000 500 0 ODDP MBF G4 A B OSRAP C CIF D JLAT (1 hr) Method These current methods (A, B, C, D) use supply requisitions data AH-64D Parts Quantity Forecast (Depth of NSNs): Phase 2 Apache Quantity (Parts) - Case 3 Methods MBF Compared to Current without JLAT (3 hr) Case 3, Stability Ops (mid-level threat), 12 months, 104 tails 90,000 MBF improves forecast parts quantity-accuracy 80,000 Total Part Quantity 70,000 60,000 Over-forecast Found (predicted qty) Found (actual qty) Under-forecast 50,000 40,000 30,000 20,000 10,000 0 ODDP MBF A G4 B OSRAP C CIF D JLAT (1 hr) Method These current methods (A, B, C, D) use supply requisitions data AH-64D Parts Quantity Forecast (Depth of NSNs): MBF Compared to Actual On-Hand Stocks Phase 2 Cost (Parts) - Case 3 $250,000,000 Savings: for 1 year $200M $200,000,000 (breadth & depth) Excess $ for incorrectly predicted parts Excess $ for correctly predicted parts = $62M Shortage of $ for missed parts Shortage of $ for correctly predicted parts Correctly predicted actual $ $150,000,000 $138M $100,000,000 $50,000,000 Subset: 4 Bn PLLs (Bn-level stocks) $0 ODDP Combo PLL+ASL Actual ODDPOn-hand Forecasted Parts rollup Rollup for for 4Bn‘s 104 tails (96 tails) Combo PLL PLL1 PLL Rollup for 4Bn‘s Bn (24 tails) (96 tails) PLL2 Bn (24 tails) PLL3 Bn (24 tails) PLL4 Bn (24 tails) 48 Analyzing Root Causes and Prescribing Innovation Working Catalysts Across the Supply Chain Towards ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (3) failure to optimize retail stock policy to achieve cost-efficient readiness (customer) objectives which results in inefficient procurement and reduced readiness; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 49 Supply Variability and Demand Uncertainty: Army Supply Chain Model Demand Uncertainty Supply Sources of Variability Acquisition Stage Wholesale Stage • Supply Depots • OEM‘s • SSAs • Repair Depots • Suppliers Unit Stage Retail Stage ―Readiness Production‖ • ASLs • OEM‘s • Training • Operations • Retrograde Operations Reverse Logistics Stage σ2 = LσD2+ D2σL2 …the ―bullwhip effect‖ qk Lk Suppliers Demand Stage q2 L2 q1 L1 Wholesale Retail q0 = D Unit Customer 25 s2 (qk) s2 (D) ―Decentralized ‖―Centralized ‖ 20 15 10 5 0 0 1 2 3 4 5 K = # of stages Adopting Mission Based Forecasting (MBF): Key enabler for a ―readiness-driven‖ supply network (RDSN) Advanced Commercial Supply Chain Focus: Bottom-up, POS based approach geared toward meeting customer demands Commodity flow Distribution Center Supplier Data flow Store Room Army Supply Chain Focus: Top-down approach geared toward meeting inventory level targets Current Forecast Data Source Current Forecast Data Source Point of Sale (POS) Recommended Forecast Data Source Parts flow Data flow Supplier Data flow ―Wholesale‖ supply, aggregated orders (requisitions) ―Retail‖ supply (inventory across multi-echelons) Consumption (parts in aircraft maintenance) 51 Army Consumption Data=Commercial POS Data Guiding Principles for Readiness-Driven Demand 1. The purpose of the materiel enterprise is to sustain current readiness and generate future capability. 2. Since readiness is ―produced‖ by tactical (and training) units, these tactical ―consumers‖ represent the ultimate ―customer‖. 3. Actual consumer demand needed to produce ―readiness‖ for training and operational missions should drive the materiel enterprise - these are customer ―requirements‖ . 4. These requirements must be systematically measured and accurately forecasted at the ―point of sale‖ where readiness is produced by the consumer. 5. Demand planning across the enterprise must focus on meeting these requirements (for effective performance) while reducing forecast error (efficient performance). Align the Class IX supply chain to ―real‖ customer demand, then pursue Continuous Performance Improvement efforts and initiatives focusing on ―Cost-Wise Readiness‖ for Army Materiel Transformation 52 Readiness Based Sparing (RBS) Item Ao $ Spares Marginal Analysis Includes: • Cost of Parts • Frequency of Use/Need • Part Impact on Readiness Shopping List Unit Added Total Cost Aircraft/ Cost ($) $10K ($) Availability Rate (%) - - - - - - - - - - - - - - - 6th A 1,600 0.388 101.600 66.67 11th B 2,300 0.352 103.900 66.69 2nd C 10, 400 0.312 114.300 66.74 12th B 2,300 0.283 116.600 66.76 1st D 13,800 0.154 130.400 66.78 7th A 1,600 0.144 132.000 66.79 - - - - - - - - - - - - - - - Analytical Demonstration: Readiness Based Sparing: 101st ABN DIV UH-60 Readiness Target Results 100 $4.8M 95 $2.2M 90 ? RBS Curve: ―The Efficient Frontier‖ $1.2M x 85 $.8M 80 $.6M 75 $.5M 70 65 0 1 2 3 4 5 ASL Investment in $M Source: AMSAA Ft. Rucker Readiness Based Sparing RBS ASL Fill Rate vs ILAP RAND EDCB • Provided first RBS ASL in 2003 (MG Dodgen) and continue to provide yearly updates • Ft. Rucker winner of 2006 and 2009 Supply Excellence Award for CAT IV (Large Group) SSA Ft. Rucker consistently has the highest fill rates in the Army Fill Rates 2002-2009 Initial Implementation 70% 2005 Update 2006 Update 2007 Update 2008 Update Fill Rate 80% 2004 Update 60% 1 81%-90% 0 71%-80% Ft. Rucker 25 41%-50% 30% Rucker (W0H) fill_rate Knox (AXB) fill_rate 10% 10 51%-60% DA Goal of 30% Fill 20% number of RICs 2 61%-70% 50% 40% 91%-100% Sill (AY5) fill_rate 37 31%-40% 45 21%-30% 44 11%-20% 22 1%-10% 17 Bragg (WAU) fill_rate 0% 0 ILAP performance rates as of March 20, 2009 20 40 number of RICs 60 ILAP performance for June 2009 12 Dec 2011 55 Analyzing Root Causes and Prescribing Innovation Working Towards Catalysts Across the Supply Chain ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (4) failure to proactively synchronize and manage reverse logistics which contributes significantly to increased DLR RO, excess inventory, increased delay times (order fulfillment), and reduced readiness while simultaneously precluding the enormous potential benefits of a synchronized, closed-loop supply chain for DLRs; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 56 Retrograde Challenge: Depot LevelLevel Reparables (DLRs) TheThe Retrograde Challenge: Depot Reparables • Represents the Army’s “Value Recovery Effort” – the “Feedback Loop” • Accounts for 13% of customer orders, but 88% of Sales Value Wholesale Retail Unit Demand ―Reverse Logistics‖ • The FY00 average reverse pipeline delay was 80 Days • AMCOM shortfall for DLR maintenance was $1.4B in 02 • Increasing obsolescence challenges will further stress RL and illuminate RCT inefficiencies, e.g. PATRIOT TWTs during OIF 57 Innovation Catalyst: Readiness ResponsiveBased Retrograde Innovation Catalyst: Readiness Retrograde Conditions: Represents ―Value Recovery Effort‖ – the ―Feedback Loop‖. Accounts for 13% of customer orders, but 88% of sales value. Research Results: Tremendous potential for reducing retrograde delay: DLR RO can then be reduced, or used for other purposes, and readiness improved. However, TRANSCOM metrics focus on transportations costs, not readiness outcomes. January 2003 – June 2004 Days N 350 12,000 FY00 study 300 250 OIF return data still truncated, and many measured from the GS base rather than from the originating unit 95% 10,000 75% 50% mean 8,000 N 200 6,000 150 4,000 100 2,000 50 0 0 EUROPE KOREA USARPAC END OUT OF OIF THEATER 58 Evaluating Retrograde Efficiency: Readiness Return on Net Assets Retrograde Efficiency Measures for management focus: Minimize: transportation costs? DLR inventory cost per aircraft? Maximize: materiel availability? DLR turnover ratio? 59 Example of IntermittentlyDemanded Service Part Compact Pneumatic Assembly M7 60 © Smart Software, Inc. 2013, All Rights Reserved Evolution of Intermittent Demand (ID) Forecasting Methods • 1st Generation: Subjective (still most used) • 2nd Generation: ID-ignorant stat methods (USAF D200) – Exponential smoothing, Moving average • 3rd Generation: ID-aware stat methods (USA LMP) – Croston’s method, Poisson and extensions • 4th Generation: State of the art ID-aware stat methods – Markov bootstrap • 5th Generation (future): Advanced ID statistical methods – Mining large sets of stochastic process data © Smart Software, Inc. 2013, All Rights Reserved 61 4th Gen – ID State of the Art: Markov Bootstrap • US Patent 6205431 B1 to Smart Software, Inc. • Positives – Highly accurate on real-world data – Explicitly accounts for key data features • Integer nature of demand • Large % of zero values • High variability in nonzero demand values • Autocorrelation of successive demands • Negatives – Assumes no trend or seasonality – … but an even better version is coming (patent pending) 62 © Smart Software, Inc. 2013, All Rights Reserved Markov Bootstrap Methodology 63 © Smart Software, Inc. 2013, All Rights Reserved ID Demand Forecast Over Lead Time 64 © Smart Software, Inc. 2013, All Rights Reserved Analyzing Root Causes and Prescribing Innovation Working Towards Catalysts Across the Supply Chain ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (5) inability to ―see‖ – and to adapt to and anticipate changes in – actual customer demand, causing inefficient procurement actions within an unresponsive wholesale stage characterized by abysmal demand plan forecast accuracy thereby precluding enterprise-wide ―cost-wise readiness‖; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 65 Innovation Catalyst: Multi-Echelon Readiness Based Sparing Innovation Catalyst: Readiness Based Sparing Conditions: Analytical Demo 101st ABN DIV UH-60 Results 100 Readiness Target $4.8M 95 90 $1.2M 85 RBS Curve: ―The Efficient Frontier‖ $2.2M x $.8M 80 $.5M 70 65 0 Research Results: - Analytical Demo revealed significant potential to reduce costs and relate investment levels to Ao. . . RBS later adopted at Fort Rucker. $.6M 75 - Low $ parts were causing Army weapon systems NMC - ―Readiness Based Sparing‖ (RBS), developed at RAND and LMI, had not been tested for Army Aviation 1 2 3 ASL Investment in $M 4 5 Source: AMSAA - Multi-Echelon RBS exhibits tremendous potential for cost savings and relating resources to Ao fleetwide. Impact of Increased Investment at Wholesale on Blackhawk Equipment Readiness at 101st Airborne Percent Increase In Readiness 5 RBS Impact? 4 3 Baseline: 2 1 Fill Rate Safety Level Readiness 70 189M 84.7% 75 210M 85.9% 80 256M 86.7% 85 340M 87.3% 90 505M 87.7% 95 857M 88% 0 0 50 100 150 200 250 300 350 400 Percent Increase in Investment at Wholesale Source: AMSAA 66 ICAAPS: Intelligent Collaborative Aging Aircraft Parts Support (LMI) SIX SIGMA, LEAN, AND THEORY OF CONSTRAINTS: CONTRIBUTIONS IN THE COST-PERFORMANCE TRADESPACE Six Sigma – improving product quality (fewer defects) by reducing process variation (variation reduction) Lean – synchronizing process flow (―takt‖ time) by removing excess WIP (inventory reduction) Theory of Constraints – improving cost effectiveness by strengthening weak links (constraint reduction) “Performance” - Availability 3 2 Improving Effectiveness 1 Lean Improving Efficiency “Investment Costs” – $ “TOC” Six Sigma 1 2 3 IMPACT of SIX SIGMA, LEAN & THEORY OF CONSTRAINTS USMC Maintenance Depot, Albany, GA Analyzing Root Causes and Prescribing WorkingInnovation Towards Catalysts Across the Supply Chain ACQUISITION WHOLESALE RETAIL UNIT Solutions DEMAND RETROGRADE (6) limited visibility into and management control over disjointed and disconnected OEM and key supplier procurement programs which are vulnerable to boom and bust cycles with extremely long lead times, high price volatility for aerospace steels and alloys, and increasing business risk to crucial, unique vendors in the industrial base resulting in diminishing manufacturing sources of materiel supplies, and growing obsolescence challenges for aging aircraft fleets; Innovation Catalysts: • Defining the Readiness Equation • Connect CBM to the Supply Chain • Mission Based Forecasting • Readiness Based Sparing • Readiness Responsive Retrograde • Leveraging Lessons Learned & Best Practices 71 CH-47 Sync Shaft Assembly Monthly Capacity Chicago Mag Finishing, coating and paint (15) (casting) 80 (M) 15 (M) Alcoa Fast120 (M) Ruscomb (studs) Timken 135 (M) (material)10 (M) w/LTA Bolt (114D3053-1) 40 (M) N/A Carpenter 10 (M) Ruscomb (material) 50 (BA) N/A Support Assembly (114D3058-8) 30 (M) 50 (BA) Bearing (145DS301-3) Subcontract 20 (M) Machining N/A 200 60 (M) 265 50 (BA) 150/mo MRC Tube (145D3400-34) AMI (material) 150 (M) Service Steel100 (M) (material) Outside processing Outside processing 30 (M) 260 50 (BA) 100-150/mo Washer (114D3044-1) 40 (M) Fluid Mech 10 (M) Jamco 22 (M) 197 15 (A) 50 (BA) N/A Mount (234DS301-2) Awaiting data (material) Notes: Purple denotes monthly capacity without impact to normal through put (M) 10 (A) 150 Lord Corp 90 (M) 50 (BA) N/A Plate Assembly (114DS344-1) Rexnord 110 (M) 160 50 (BA) N/A Boeing Findings and Concerns • Supply chain plagued by extremely long and growing lead times • Companies in the supply chain are averse to risk and investment resulting in little or no inventories • There are very few long term contracts • Essentially no visibility of downstream demand in supply chain • Suppliers are very concerned about demand uncertainties and financial viability over the next 5 years. • Continuous improvement programs are limited to localized manufacturing processes • Specific vulnerabilities: – raw material price escalation – union contract negotiations – sole suppliers for many parts and required specialty steels • Common issues across multiple aviation platforms “Instead of protecting the 20th Century defense industrial base , government and industry need to transform it into a 21st Century industrial base that can justify its existence by providing needed military equipment at an affordable price. This requires an across-the-board transformation – including infrastructure, equipment, workforce, and the defense industry at large.” From Democracy’s Arsenal: Creating a 21st Century Defense Industry, by Jacques S. Gansler, former Under Secretary of Defense for Acquisition, Technology, and Logistics 1997-2001 Part III. Enterprise Integration: Prescriptive Analytics for Efficiency, Resilience, and Effectiveness 12. Achieving Efficiency: An Integrated Multi-Echelon Inventory Solution 13. Designing for Resilience: Adaptive Logistics Network Concepts 14. Improving Effectiveness: Pushing the Logistics Performance Envelope Increasing “Effectiveness” in the Cost -Availability Tradespace Achieving “Efficiency” in the Cost Availability Trade Space Cost Benefits Alternatives: 2 3 ―Efficient Frontier‖ 4 Ao Gain in ―Efficiency‖ Ao 1 1. Improved effectiveness with increased costs 2. Improved effectiveness at same costs ―Efficient Frontier‖ 3. Improved effectiveness at reduced costs 4. Same effectiveness at significantly reduced costs … however, magnitude of each depends upon where you are on the current efficient frontier! … and the expansion trace of the improved frontier $ $ (7) independently operating, uncoordinated and unsynchronized stages within the supply chain creating pernicious ―bullwhip‖ effects including large RO, long lead times, and declining readiness; (8) fragmented data processes and inappropriate supply chain MOEs focusing on interface metrics which mask the effects of efficient and effective alternatives, and further preclude an ability to determine ―readiness return on net assets‖ or to relate resource investment levels to readiness outcomes; 74 Achieving Multi-Echelon Integration Achieving MaterielEfficiency: Enterprise Efficiency: Multi-echelon Integration SingleEchelon Supplier MultiEchelon Supplier Lead Time Lead Time Supplier Wholesale Wholesale Inventory Drivers Inventory Drivers Lead Time Retail Supplier Lead Time Lead Time Wholesale Replenishment Optimization Wholesale Inventory Drivers Lead Time Lead Time Inventory Drivers Demand Retail Retail Inventory Drivers Inventory Drivers Demand Customer Customer Inventory Drivers Retail Replenishment Optimization Demand Customer Sequential Approach Network Replenishment Optimization Retail Inventory Drivers Demand Customer Multi-Echelon Approach 75 Current Vertical Supply ―Chain‖ Structure Design for Resilience: Demand Driven Supply Design for Structural Resilience: Readiness Driven Supply Network Network (DDSN) SSA SSA ASL ASL SSA DDOC SSA NICP ASL SSA DDOC DDOC SSA SSA SSA RBS Cost/Item List • RBS reduces cost • Inventory pooling reduces both A cost and risk • Lateral supply decreases requisition delay time & increases Ao SSA RBS Stock List $ Hi CostLow Demand DLRs • Low Cost Consumables • Hi Demand Parts 77 Pursuing Cost-Effective Readiness: Pushing the Performance Envelope Increasing “Effectiveness” in the Cost -Availability Tradespace Cost Benefits Alternatives: 2 3 1 4 ―Efficient Frontier‖ Ao 1. Improved effectiveness with increased costs 2. Improved effectiveness at same costs 3. Improved effectiveness at reduced costs 4. Same effectiveness at significantly reduced costs … however, magnitude of each depends upon where you are on the current efficient frontier! … and the expansion trace of the improved frontier $ 78 Part IV. Predictive Analytics for Design and Evaluation: An ―Analytical Architecture‖ to Guide Materiel Enterprise Transformation 15. Multi-Stage Supply Chain Optimization 16. System Dynamics Modeling and Dynamic Strategic Planning 17. Operational and Organizational Risk Evaluation 18. Logistics System Readiness and Program Development 19. Accelerating Transformation: An ―Engine for Innovation‖ Capacity (What we can do) Knowledge (What we know) Inventory (What we have) (9) lack of central supply chain management and supporting analytical capacity results in multiagency, consensus-driven, bureaucratic workarounds hindered by lack of an Army supply chain management science and an enabling ―analytical architecture‖ to guide Logistics Transformation; (10) lack of an ―engine for innovation‖ to accelerate then sustain continual improvement for a learning organization. 79 Improving System Efficiency: Across the System of Stages and within each Stage Acquisition Wholesale Retail Unit Demand 10 1.1 Numeric Stockage Objective 1.0 Repair Cycle Stock Due Out 8 3.4 6 Procurement Cycle Production Lead Time Administrative Lead Time 4 2 2.1 Safety Level 0.5 Below Depot SSF RO 0.8 0.3 1.4 0 War Reserve $160,000 Reverse Logistics $140,000 Safety Stock AMC Requirements Objective ($ in Billions) 12 Because inventories are managed to the computed RO, reducing the value of the RO calculated by AMC’ AMC’s models is a critical first step to reducing inventories. Baseline Cost Optimized Cost $120,000 $100,000 $80,000 $60,000 $40,000 $20,000 $0 50% 60% 70% 80% Service Level 90% 100% 80 ―Optimizing‖ the System: Applying a Dynamic (Multi-Stage) Programming Model N $ 2 $ Wholesale Stage 1 $ Retail Stage 5 Unit Production Stage Ao 100 $4.8M 95 4 $2.2M 90 $1.2M 2 85 $.8M 80 $.6M 75 $.5M 1 80% MC 70 0 90% MC Labor 3 Readiness Target Acquisition Design Stage Percent Increase In Readiness $ 3 65 0 50 100 150 200 250 Percent Increase in Investment at Wholesale 300 350 400 0 1 2 3 Investment in $M 4 5 Capital 81 Supply Chain Framework Supply Chain Framework ReCap & ReSet Demand Inventory Vendors Orders to Vendors MATERIAL FLOWS Inventory Wholesale Inventory Retail Orders to Wholesale Inventory Unit Demand Orders to Retail INFORMATION FLOWS OMA Funding Available AWCF Payments to Vendors and Depots ReCap & ReSet Funding Obligation Authority OMA Funding FUNDING FLOWS 82 Logistics Readiness and Early Warning System Logistics Readiness Early Warning System Feedback Automated Monitoring - Readiness trends and forecasts - Supply chain metrics - Logistics system readiness parameters Alert Policy Response - HQDA reviews - Analyze and implement cost-effective options - Minimize recognition and response bags - PPBES implications (resources-to-readiness) Management Assessment Warning - Corroborate and validate alerts - Assess near and long-term implications - Integrate empirical evidence with human judgment The regression relating Mission Capable rates (MC) to age lagged 5 months, shown in the equation below, indicates that a one-month increase in backorder average age leads to a reduction of 2.8 percentage points in MC rate 5-months hence. The coefficient is highly significant (at the one percent level), and the R2 is 63 percent. MC = 0.97 – 0.028 (Age lagged 5 months) 83 An ―Engine for Innovation‖: The Center for Innovation in Logistics Systems (CILS) FFRDC‘s Non-Profits Academia (1) Magnet, Filter and ―Repository‖ for ―Good Ideas‖ Corporate Research • • • • • Tactical Units Organizational Design Supply/Value Chain Workforce Development Technology Implications Innovation & Productivity Gain • R&D DoD Organizations Professional Societies: INFORMS (2) Modeling, Simulation & Analysis of Complex Systems Academic Institutions Commercial Sector • System Dynamics Modeling • Large Scale System Design, Analysis, and Evaluation • Systems Simulation, Modeling and Analysis • Repository for validated models & analytical tools Public (3) Transforming Organizations & Managing Change Private • Cost Benefit Analyses • Risk Reduction & Mitigation • Research, Studies, and Analysis • Education & Training • Technical Support • Change Management 84 Part V. Management Concepts for Materiel Enterprise Transformation 20. Organizational Redesign for Army Force Generation 21. Contributions of Information Systems Technology and Operations Research 22. PBL and Capabilities Based Planning for an Expeditionary Army 23. Financial Management Challenges to ―Business Modernization‖ 24. Human Capital Investment for a Collaborative Organization 25. Strategic Management Concepts for a Learning Organization 26. Final Thoughts Civilian ―ORSA‖ (1515) Strength in AMC Officer ORSA (FA49) Strength in AMC History of FA49 Authorizations in AMC 60 2,500 COL LTC MAJ CPT 50 ALL ARMY 2,000 AMC 30 1,500 20 10 FY98 FY99 FY00 FY01 FY02 FY03 1 1 1 0 0 0 0 LTC 9 9 6 6 6 5 5 3 3 1 2 1 0 0 0 0 MAJ 12 15 11 11 11 14 8 5 6 2 1 2 0 0 0 0 CPT 25 24 28 28 28 7 4 4 4 0 0 0 0 0 0 0 500 31.84% FY97 2 32.61% FY96 2 33.66% FY95 2 34.29% FY94 2 37.02% FY93 3 37.75% FY92 3 37.21% FY91 3 40.41% FY90 5 39.92% FY89 5 41.00% FY88 42.81% 0 COL 44.10% 1,000 41.99% Authorizations 40 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 0 85 Integration Opportunity: ARFORGEN Synchronization - RBS Integration Opportunity – RBS for ARFORGEN 3 2 90% MC Labor Ao 60% MC Capital 1 Available Ready Reset 80% MC $ 86 Integration Opportunity: ARFORGEN Synchronization Integration Opportunity: RBS and MBF for the Army‘s new Regionally Aligned Force Concept MBF and RBS Europe CONUS 111 84 111 87 CONUS vs IraqStab CONUS vs IraqMCO 2833 2833 PMO Apache 88% 71% Pacific 29% RBS Curve: ―The Efficient Frontier‖ 27% 59% SWA CONUS IraqMCO CONUS 41% IraqStab Available Ready 90% MC Labor Ao 73% 12% Reset 80% MC 60% MC 87 $ Capital Integration Opportunity: Logistics Support for Integration Opportunity: ―Advanced Analytics‖ for a Capabilities Based Force Capabilities Based Planning CONUS vs Iraq Stab 73% 27% 59% CONUS Defense Planning Guidance Scenarios 41% IraqStab MISSION SCENARIOS Readiness Equation REVISED CLASS IX STOCKAGE POLICY *EG: IDEEAS, JANUS, JCATS CASTFOREM, JTLS 88 Integration Opportunity: Product Integration Integration Opportunity: ProductSupport Support Integration for (PSI) for PBL Performance Based Logistics (PBL) Aligning PBL Incentives to Readiness Outcomes The Fallacy of ‗Fill Rate‘ as an Incentive for SC Performance Maximum difference between Total Revenue and Total Cost or Maximum Profit Total Cost Function Value of Cost or Output (Return) Ao/FR/Score Production Function (A0 * VPC) Tangents of equal slope Avg. Delay 1.0 100 .9 Steep here means shallow here Decision or Stopping Points (Iterations) PBL Contract Scoring Regime Results .8 90 What the customer wanted 80 .7 70 .6 60 .5 50 .4 40 ($ 000,000s) 10 .3 Legend Award Fee Cost Profit Max Profit 9 8 Legend What the customer got .2 Ao Fill Rate Avg. Delay Max Profit Score 7 .1 6 30 20 10 0 0 5 0 5 10 15 20 25 30 35 40 45 50 4 Inventory Value* ($ 000,000s) 3 2 1 0 0 5 10 15 20 25 30 35 40 45 50 Inventory Value* ($ 000,000s) 89 Management Innovation as a Strategic Technology Management Innovation: Technology Innovation: Customer Needs •MERBS1 •CBM6 •MBF2 •RFID7 •R33 •TAV8 •DSLP4 •LREWS5 1Multi Methodology Advancement Technology Enablers •ERP9 Echelon Readiness Based Sparing 2Mission Based Forecasting 3Readiness Responsive Retrograde 4Dynamic Strategic Logistics Planning 5Logistics Readiness and Early Warning System 6Condition 7Radio 8Total Based Maintenance Frequency Identification Asset Visibility 9Enterprise Resource Planning 90 Contributions of Information Systems Technology and Operations Research: ―Advanced Analytics‖ for Enterprise Strategy and Integration Vision & Strategy Programs & Resources Vision Quantitative & Qualitative "Analysis" Strategy Decision Support System ERP (SALE) Databases "Readiness" • Traditional Weapon System "A 0" • Program Sustainment • Capability to Meet Operational Needs 91 Linking Processes and Systems with Operational and Financial Performance Mature Immature Business Processes Lack of System Support Planning Practices and Systems Aligned Improved bottom line profitability 27% improvement potential B Significant improvement on operational performance 75% higher profitability for BIC C Single Site, Informal and Manual Planning Processes Below average business performance Systems are not Complemented by Planning Practices Significant Inefficiencies A Immature D IT Systems Mature As of FY 2011: GAO found DoD ERP implementation delays ranging from 2-12 years with cost increases of nearly $7 billion; for the Army, LMP reported more than $10.6 billion in ―abnormal balances‖ within the Procure-to-Pay general ledger accounts. 89 Common Expectations and the Reality of Change Performance Anticipated Performance C? B? Historical Performance A The Reality of Change Disruption D? Source: Professor Rebecca Henderson MIT Sloan Time Mature Immature Business Processes Linking Business Processes and IT Systems with Operational and Financial Performance Advanced planning practices Immature IT Systems Advanced planning practices & advanced IT systems—aligned B C Single sites, Informal and Manual Planning Processes Advanced IT Systems — not complemented by advanced planning practices A D Immature Mature IT Systems Performance Common expectations and the reality of change Anticipated Performance C B Historical performance The Reality of Change A Disruption Time D Sustaining Innovation While Linking Execution to Strategy A.D. 80 A Keystone in Time: The voussoir arch in the Roman Empire A.D. 2012 Current Global ―Tectonic Stresses‖ & ―Grand Challenges‖ for Engineering Systems: Population Energy Environmental Climate Economic • Operations Research • ―Advanced Analytics‖ • MIST ― . . .the organizational ‗glue‘ needed to coordinate, orchestrate, and pull the enterprise together to keep it focused and continuously learning, precluding chaos during a period of transformational change.‖ Confronting the ―Engenuity Gap‖: Operations Research and Management Innovation for Enterprise Systems 96 2nd International Conference on Operations Research and Enterprise Systems (ICORES) 2013 Barcelona, Spain ―Transforming a Complex, Global Organization: Operations Research and Management Innovation for the US Army‘s Materiel Enterprise‖ Greg H. Parlier, PhD, PE Colonel, US Army, Ret gparlier@knology.net 18 February 2013 97 ―Formulas‖ 1. ―Advanced Analytics‖ = Descriptive + Predictive + Prescriptive Analytics 2. Management Innovation as a Strategic Technology (MIST): MIST = OR[MIS + DSS] + TSP[EfI + STAAMP] + IMS where: (see handout) 3. f(D x VL x F) > R where: f = ―forcing‖ function (for organizational change) D = dissatisfaction VL = visionary leadership F = first steps -- the compelling analytical argument for change R = resistance -- bureaucratic and/or organizational 98 ―Literature Search‖ – A Few Suggestions • MIT Series on Engineering Systems: – Engineering Systems: Meeting Human Needs in a Complex Technological World; deWeck, Roos, and Magee – Flexibility in Engineering Design; deNeufville and Scholtes – Design Structure Matrix Methodology and Applications; Eppinger and Browning • Design of Enterprise Systems: Theory, Architecture, and Methods; Giachetti • Transforming US Army Supply Chains; Parlier • The Engenuity Gap: How can we solve the problems of the future? Homer-Dixon • Consilience: The Unity of Knowledge; EO Wilson • Operational Research in the RAF; Her Majesty’s Stationery Office, 1963 • Democracy‘s Arsenal: Creating a 21st Century Defense Industry; Gansler 99 Traditional (Incremental) vs. Transformational Strategic Planning Transformational Vision Imagineering Back to Present Business Growth Horizon 3 See & „Architect‟ Architect‟ Options for Future Business Growth Horizon 2 Drive Growth in Emerging New Businesses Horizon 1 Defend and Extend Existing Business Time Leading from the Present Leading from the Future 100 The Aggregate Impact of Both Uncertain Demand and Variable Supply Impact of Variable Supply Lead Times RO Impact of Variable Demand Rates RO L1 ROP L2 L3 D3 ROP D2 D1 Time Time RO =LxD ROP ºº F(x) = y(x/t)g(t)dt º σ2 = LσD2+ D2σL2