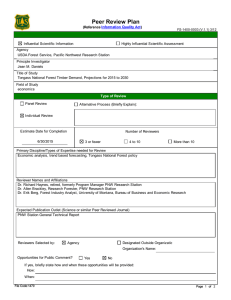

Sawmilling Technology Application in Commodity Products Abstract

advertisement