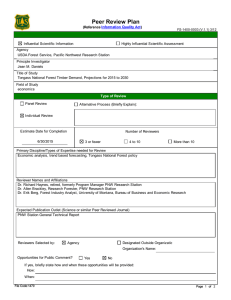

Document 11914548

advertisement