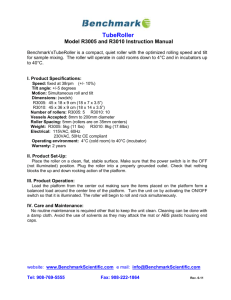

J.D. Neuhaus Vertical Roller Mill Maintenance Hoists Features and Benefits

advertisement

J.D. Neuhaus Vertical Roller Mill Maintenance Hoists Features and Benefits Capacities up to 200 tons Low Headroom Reliable in Dusty Environments JDN Quality Low Air Consumption Industry Group: Hoist Manufacturers Institute (HMI) JDN Roller Pair Handling Systems allow the plant operator to safely and conveniently remove and replace the roller pair without the need for mobile cranes or other external lifting equipment. This can reduce plant downtime and eliminate the costs associated with using a mobile crane. Systems are available in capacities to 200 metric ton (2 X 100t). All systems are air powered and require standard operating air pressure of 85-90 psi. The rugged JDN design is ideal in the rough environment of most cement plants. 16 of the 32 trolley wheels are powered to provide positive horizontal travel in the dustiest conditions. A powerful vane motor is self lubricating, uses very little air and requires a minimum of maintenance. Custom design clevises or other attachment are available to connect to the roller pair to minimize headroom requirement. The pneumatic hoists are not affected by the dusty environment of cement plants and can be equipped with an automatic shutoff device to prevent overloads. A transfer beam is extended into the kiln and the air powered monorails are run in over the rollers. Both hoists and trolleys are operated from a single pendant control located below the hoists which allows the operator to see the progress of the job and be able to react quickly and safely as the rollers are removed. J.D. Neuhaus L.P. 9 Loveton Circle Sparks, Maryland 21152 Phone: 410-472-0500 j.mcgarry@jdneuhaus.com www.jdneuhaus.com