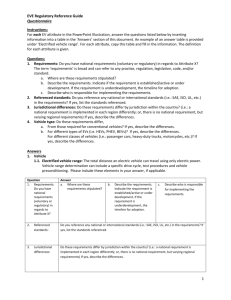

1 maximum speed of 20 mph, ... [3].

advertisement

![1 maximum speed of 20 mph, ... [3].](http://s2.studylib.net/store/data/011902209_1-2999dd5b4e89845f3c3ee3a982412912-768x994.png)

1 Electric Vehicles A. Asbury, C. Bruffey, R. Clinard, B. Bowles, L. Wu, W. Ju Electrical Engineering and Computer Science Department University of Tennessee Knoxville, USA A. 1 Abstract—The recent proliferation of electric vehicles (EVs) has been a cause for reflection and intensified research in the field. EVs have a storied history just as long as gas-powered vehicles. However, lack of innovation has caused electric vehicles to endure long periods of disuse. New state-of-the-art designs have had impacts on society and EV manufactures. These new designs present new challenges to consumers wishing to use an electric vehicles and utilities wishing to alleviate this stress on the grid. With the large-scale integration of EVs, benefits to the frequency regulation of the power grid and improvements to the distributed spinning reserve of the power grid will be observed. Index Terms—Electric vehicle, Environmental impacts, V2G, Battery Technology, Frequency Regulation E I. BASIC THEORY LECTRIC vehicles use a battery to store energy, though some designs use fuel cells or have auxiliary engines. These supplemental energy sources can be utilized to charge the battery when additional range is needed by the driver. This scheme is often referred to as a hybrid electric vehicle. The stored energy is passed through sophisticated power electronics to a motor. These motors can be either DC or 3phase AC; each configuration has its advantages. DC motors have an overdrive feature, allowing them to be driven at a higher than rated power for short periods. While AC motors lack the overdrive feature, they can incorporate a regeneration mode. In regeneration mode, the motor may convert its rotational energy into electricity to be stored in the battery [2]. Electric vehicles have evolved from simple machines of the 19th century into complex, computer-controlled supercars. II. HISTORY A. Early Innovations English inventor Thomas Parker invented one of the first practical EVs in 1884. Early electric vehicles were relatively successful in the market. According to one survey at the beginning of the 20th century, 40 percent of American automobiles were powered by steam, 38 percent by electricity, and 22 percent by gasoline [3]. Each of these nascent technologies had major flaws. The steam-powered cars were hindered by a long startup period, reaching up to 45 minutes on cold mornings. Gas powered cars were loud, dirty, and had to be started with a hand crank. Therefore, even though the electric vehicles were limited to about an 80-mile range and a maximum speed of 20 mph, they still made viable city cars [3]. By the turn of the century, some companies were using EVs to provide taxi service. These services introduced the idea of electric vehicles to the wider public. These early electric vehicles were more expensive than gas-powered cars at the time and were mainly targeted at upper class, urban households. Ironically, the invention of the electric starter and muffler for gas vehicles would sound the death knell for these early electric vehicles. Though during times of hardship and rationing, such as World War II, some countries made limited use of electric vehicles. Overall EVs fell almost entirely out of use except in some very niche roles, such as local milk delivery trucks [3]. B. Intervening Years It was not until the energy crises of the 1970s that EVs once again began to see earnest attention. The Sebring-Vanguard Citicar was introduced in 1794; it would hold the record of most units sold by a North American manufacturer until 2012 and the Tesla Model S. However as public memory of the energy crisis faded, so did development of electric vehicles [3]. C. Recent History It would not be until the 1990s, and the actions of the California Air Resources Board (CARB), that EVs would see mainstream support and success. The board mandated a shift towards zero emission vehicles, which prompted large auto companies to create limited numbers electric vehicles. Eventually, CARB’s mandate was rescinded; however, EVs retained some momentum and took on something of a cult status. From the 1990s through today, electric vehicles have seen an extended period of continuing interest and development. Unlike previous eras of the electric car, major manufacturers of traditional, gas-powered cars have invested heavily in the new electric car market [3]. They share this space with many new startup companies looking to make an impact in a rapidly developing market. III. STATE OF THE ART DESIGNS As we can see, electric automobiles are not a new technology. Some of the first vehicles were, in fact, powered by electricity. Despite the almost complete disappearance of electric vehicles from consumer markets for the better part of a century, there has been a resurgence of interest in electric vehicles that has spawned new advancements in electric vehicle design. 2 A. Detroit Electric’s SP.01 While there are many electric vehicles currently on the market, the newest and most advanced designs tend to be higher priced sports cars. Although these vehicles are cost prohibitive for the majority of consumers, they showcase the potential that electric vehicles have as the technology matures. Detroit Electric, a modern company named after an electric vehicle pioneer, has announced a limited production run of the SP.01 roadster. The vehicle has an aluminum chassis and carbon fiber body to reduce weight. Powered by a 150 KW electric motor, this two-seat all-electric vehicle boasts a 0-60 mph time of 3.7 seconds and a top speed of 155 mph. The most innovative feature is the 37 KWh lithium-ion polymer battery pack. In an effort to maximize performance, the battery backs are climate controlled by conditioned air and heat. Detroit Electric will monitor the health of all SP.01 vehicles through a telemetry link, giving the company real time information about each battery and drivetrain. The battery is also equipped with the “Powerback-360” option, which allows it to be connected to the power grid or to be used as an emergency source of power. live and die by the opinions of the consumer. The importance of customer satisfaction is growing even more important as we progress through the age of instant communication that we see in today’s society. B. Tesla’s Model S P85 D Not to be outdone by a newcomer to the performance electric vehicle market, Tesla has announced the newest version of their Model S sedan, the dual motor Model S P85 D. By using one motor for each axle, Tesla has produced an all-wheel-drive electric vehicle that has a 0-60 mph time of 3.2 sec., on par with the some of the fastest combustion engine vehicles ever made. It also boosted the vehicle’s top speed to 155 mph. The most innovative feature of this vehicle has yet to be realized at this point. Because the two motors give the onboard computer better control of the vehicle, Tesla is equipping every Model D with the ability to use an autopilot feature to be installed later. The autopilot will make use of sensors to avoid collisions, stay in its lane, and even change lanes. Future plans include radar for snowy and foggy conditions and 360-degree ultrasonic sonar. Vehicle Type MPG or MPC Gas vehicle eV (Tesla P85) eV (Nissan Leaf) C. Harley-Davidson’s Project LiveWire Not all electric vehicles are cars, however. While the majority of the innovations in electric vehicle technology are designed for the car, some innovations are occurring in the motorcycle market. Harley Davidson is touring the country to gain feedback from riders about their new all-electric Project LiveWire motorcycle. Harley Davidson, always known for having distinctive sounding motors, designed the 74 HP, 3phase AC motor to have a unique sound, which has been described as sounding like “a fighter jet taking off.” Harley Davidson has announced that it will tour Project LiveWire across the United States and Canada to determine interest before deciding whether it will enter production. IV. IMPACTS When talking about the technical and social impacts of electric vehicles we must be concerned with the impacts from a consumer’s point of view. This is important since companies A. Carbon Emissions The technical impact that is of the most concern is the emissions savings that a consumer would gain when switching from a gas-powered vehicle to an electric vehicle. The chart below shows the comparison of three vehicles: an example gas vehicle rated at 25 mpg, a Tesla Model S P85 [5], and a Nissan Leaf [6]. The chart shows the emissions per mile of each vehicle (miles per metric tons of CO2) with the Nissan Leaf being 61.1% more efficient, and the Tesla P85 being 60.7% more efficient than the gas model. Emissions savings vary by your location as well [4]. Areas with a larger supply of green energies (solar, wind, hydro, nuclear) will experience a higher efficiency than those areas that are supplied by coal fired power plants [7]. TABLE I SUMMARY OF EVNIRONMENTAL IMPACTS OF ELECTRIC VEHICLES Metric tons of CO2 per kWh 25 265 Metric tons of CO2 per gallon 8.887x10-3 - 6.89551x10-4 Miles per metric tons of CO2 2813.1 4521.3 75 - 6.89551x10-4 4531.9 B. Battery Recycling Another important technical impact would be that of battery lifetime and disposal, as that would be an extra cost to the consumer. The guaranteed battery life of both aforementioned electric vehicle models is 8 years or 100,000 miles. Tesla offers a battery exchange program that allows owners to exchange their vehicles battery after 8 years [5], but Nissan offers no such program [6]. Currently there are no major battery recycling programs, as it is not currently economical for companies to get into the market. However, it is estimated that by 2035 there will be somewhere between 1.3 million and 6.7 million depleted EV batteries in the United States alone. That will be sufficient to justify commercial recycling and reuse programs [8]. C. Cost Considerations Perhaps the largest of concerns to consumers would be the social impact of cost. The cost of buying an EV is significantly higher its gas-powered counterparts, but this may be offset some by potential reimbursements from federal, state, and local governments and savings from fuel costs over time. On average, Americans drive 13,676 miles per year or 1123 miles per month [9]. The chart below shows the cost differential between the two vehicles, with an electric vehicle saving the hypothetical consumer nearly $100 per month compared to the gas vehicle. It is important to note that price of gas is very volatile compared to the price of the kWh. 3 TABLE II COST OF OPERATION FOR ELECTRIC VEHICLES Gas Vehicle Electric Vehicle 25 mpg - $3.00 per gallon $0.11 per kWh $135 per month $39.64 per month D. Range Limitations on the Consumer Another social impact that limits the electric vehicle is the capacity of the battery and how that translates to traveling outside of the daily commute. The Tesla Model S P85 has the highest battery capacity at 85 kWh but that only allows for 265 miles, which means that a long road trip would require stopping to charge the battery. There are charging stations throughout the country and the number of those charging stations is increasing steadily, so it is possible to charge the battery and make those trips with proper planning [10]. Tesla is currently implementing the Supercharger stations throughout the country, which allows the driver to charge his or her Tesla in 30 minutes [11]. This charge gives you about 170 miles, but will still have a dramatic effect on the drive times on a long road trip. It should be noted that as more of these charging stations appear and electric vehicles enter the roadways, the strain on the power grid will increase. This strain could prove to be problematic if these chargers are not powered by a local alternative fuel source (solar or wind). V. CHALLENGES TO ELECTRIC VEHICLES To underscore the potential impact of wide scale electric vehicle adoption, multinational research and design initiatives are underway between various world powers focusing on improving efficiency, cost, safety and performance in EVs. In the United States, President Barak Obama recently issued the “EVs Everywhere Grand Challenge”. The goal of this initiative is to enable US companies to produce electronic vehicles that are as convenient and affordable for the average American family as today’s gas powered vehicles by 2020 [12]. The President’s initiative focuses on working with industry, universities, and national laboratories to set goals for cutting costs in energy storage technology and powertrain systems, increasing fast charge rates, reducing vehicle weight without sacrificing safety, and developing the supporting infrastructure. A. Battery Technology Energy storage technology is currently the central focus of research and development efforts [13]. In order to make EVs a viable alternative to gas powered vehicles, advancements in energy and power density as well as affordability and safety must be made. Battery aging is another area in electrochemical storage technology that is receiving attention. Given that factors in battery aging range from physical cell design to driver habits, research and testing can be time consuming and costly. This predicament makes multinational collaboration very important. Currently, researchers at Oak Ridge National Laboratory are in the midst of developing technologies that provide higher energy and power densities without sacrificing safety or performance. One such technology is the LithiumSulfur battery. Li-S batteries have extremely high energy density, double that of the current Lithium-Ion technology. Additionally, Li-S batteries would be cheaper and lighter. This is due to the abundance and moderately low atomic weight of the element. In fact, the density of a Lithium-Sulfur battery is roughly that of water [14]. Interestingly, one of the technologies greatest draws is also one of its major drawbacks: the incredibly high energy density the battery provides also requires additional safety features and precautions to prevent rapid discharge, such as microcontrollers and other safety circuitry as well as increased demands on enclosure design. B. Drivetrain and Auxiliary Systems While battery technology is the major focus, great strides are being made regarding safety, cost, efficiency, and performance in the areas of drivetrain and auxiliary systems, and motors. Drivetrain research and development is focused mainly on reducing friction and wear through advanced lubricants as well as increasing range, efficiency, and performance through the development of lightweight materials that do not sacrifice safety. Auxiliary systems such as climate control are being refined to reduce energy consumption for passenger comfort via advanced insulation materials and more ergonomically correct placement of vents. Motor research focuses on reducing cost, weight, and volume while maintaining or increasing performance, efficiency, and reliability. Efficient thermal management is another challenge to increasing efficiency and cost effectiveness. In order to meet the 2022 cost targets, research must reduce motor cost by 50% [15]. One way this is being addressed is by reducing the use of rare earth materials inside the rotor magnet. Not only does this reduce cost, it helps to conserve some of earth’s finite resources. C. EV Power Electronics Advancements in power electronic devices are also bringing society closer to the goal of widespread EV adoption. In fact, some of the most exciting developments have been in this area. Currently, converters and inverters face issues with subcomponents that lack sufficient tolerance to high temperatures, premature component failure due to insulators that inhibit heat transfer from electronic devices, and a mismatch in how much power electronics and their supporting structures change in response to temperature fluctuation [16]. These challenges, among others, are being address through research in the following areas: advanced power electronics subcomponents, insulating compounds, improved inverter design, device packaging, and improved onboard charger designs. Advanced PE subcomponent research is predominantly focused on wide band gap semiconductors. These new semiconductors offer significant advances in performance while reducing the cost of vehicle power electronics [17]. Additionally this new design can withstand higher temperatures, thus reducing thermal management requirements. Oak Ridge National Lab is currently 4 developing epoxy-molding compounds that conduct heat at higher rates than current materials. The implementation of these compounds could improve component longevity and operating efficiency. Researchers are also currently experimenting with new inverter designs that utilize high temperature capacitors that could reduce inverter cost and volume while improving heat tolerance and efficiency. Reengineered device packaging is currently being researched with the potential to eliminate existing interface layers and provide cooling at or very near the heat source, providing some alleviation of the temperature reaction mismatch between PE devices and their supports, as well as efficiency and weight reduction benefits. On board charging research is being conducted to potentially implement the charging function into other existing PE devices and utilize the inductance of the electric motor for recharging [17]. This is engineering ingenuity at its finest. D. EV Grid Integration The final major area of research and development for the future of electric vehicles is integration of EV technology to the grid and creation of the supporting infrastructure. The shift to wide scale adoption of EVs requires a shift to accommodate them. Governments both local and national must overcome significant challenges if the goal is to be achieved. These issues include increased transmission, distribution, and generation requirements as well as developing standards in EV charge equipment, management of shared resources including coordinating and planning access to charge stations, minimizing power spikes and managing charging demands during peak load times. Impacts on neighborhood distribution systems must be analyzed in order to minimize transformer load and phase-to-phase imbalances incurred by multiple EVs charging off the same transformer. Additionally, the logistics of installation, billing, management, and access to charging stations in dense residential and commercial areas must be addressed. Many local governments are working to facilitate EVs due to the economic and environmental benefits as well as receiving federal aid for spearheading this objective. Additional research is also being done to implement micro-grids that rely heavily on renewables instead of power from the grid at large [18]. This technology will be invaluable in mitigating strain to the United States’ already antiqued grid. VI. SUCCESS STORIES A. Tesla Motors Currently, Tesla Motors [19] is the most successful example of EV marketing; it is an American company, which designs, manufactures, and sells electric cars and electric vehicle powertrain components. Tesla gained widespread attention following its production of the first fully electric sport car. The CEO of Tesla Motor, Elon Musk, a talented entrepreneur from Silicon Valley (SV), founded Tesla Motors and several other well-known companies, such as: SolarCity, Paypal, and SpaceX. The development of Tesla is closely associated with the creative spirit of SV entrepreneurs. There are primary three cornerstones for Tesla’s success: state-of-theart technologies, unique marketing strategy, and potent government support plus sound after-sell service. Tesla is the first company that focuses on pure electric propulsion technologies. The state-of-the-art technologies are its essence in order to survive in the vehicle market, such as high energy-density battery packs, flexible power control, light and hard carbon fiber body, etc. Some of the technologies, battery pack and power control module are briefly introduced as follows. The design of battery pack [20] in Tesla’s EV is the result of innovative systems engineering and 20 years of advances in Lithium-ion battery technology. It has the most energy density in the industry, which is constructed of 69 batteries connected in parallel first, with 9 bricks connected in series, and finally 11 sheets connected in series. In total, the pack contains 6831 lithium-ion batteries for storage of 56kWh energy, being able to be charged from any 120 volts or 240 volts outlet. Tesla utilizes a power electronic module for flexible control of the DC and AC power exchange in its EV. It functions as a bridge between the charge port, battery and the motor. When charging, it converts AC from the wall into DC for energy storage in the battery; when driving, it converts DC in the battery into AC for motor to generate torque. Electric vehicle application is a high-cost business due to its high technologies, so it is difficult for the companies to gain useful profits and develop their business in the market while competing with relatively cheap gas-engine vehicles. However, Tesla survives by virtue of a unique marketing strategy. At the beginning, it targeted to the open market by selling sport cars to high-end customers. Because only these people can afford their vehicles, they utilize these substantial profits to open the EV market to normal customers. After a period of financial revenue collection, it gradually explores more markets of the middle-class customers. As a renewable and clean energy application company, Tesla obtains potent government support, such as tax deductions, low bank loan interest rates, etc. Furthermore, it provides sound after-sell service to deal with typical technical problems, like free batteries maintenance in the first 8 years, flexible products exchange policy, etc. These policies and services can effectively stimulate customers to own Tesla’s electric vehicles. A common concern for EVs is the capability of extending range, because the battery always needs to be charged, and it is not as convenient as conventional cars, which can be easily filled with fuel at a gas station. Recently Tesla released a supercharger network program to resolve this concern, cooperating with Solar City, another company Elon Musk owns for exploring solar power application. The program’s target is to build over 200 supercharger stations all over North America. By the end of 2015, it will cover over 98% of the U.S and Canada. Charging for 20 minutes, the batteries can then support a 150-mile drive, with 10 minutes more charge adding an additional 50 miles range. Tesla’s customers would easily 5 obtain battery charging and drive any additional range in North America. B. GM’s Chevrolet Volt For the same concern, there is another solution implemented by General Motor on their successful EV application: Chevrolet Volt [21]. It is the top selling plug-in hybrid electric vehicle in the USA. The Volt is named as a hybrid EV due to the creative design of its powertrain [22], a combination of an internal combustion engine and an electric motor along with a battery, which can be charged by connecting a plug to any external electric power source, normally just wall outlet. It can operate as a pure electric vehicle for the first 25 to 50 miles. When the battery energy drops down to a pre-determined threshold, the gas engine will start to work and provide additional range. With this system, customers do not have to worry about running out of battery energy. No matter electricity or gas, they can obtain the energy conveniently. Figure 1. Schematic diagram of the frequency regulation based on EV VII. RELATED RESEARCH LITERATURE ON ELECTRIC VEHICLES Vehicle-to-grid (V2G) system can provide active power support and frequency regulation services to mitigate the intermittence of renewable energy sources (RES), and balance the loads in the power grid. To perform the frequency regulation, we need a large deployment of EVs. Meanwhile, in order to manage a large number of EVs, it must have some extra equipment including [23]: a smart interface with the grid, communication with the grid operator and metering the exchange of information power flows of the grid. These requirements bring more challenges to power grid in the process of frequency regulation, such as the coordination between the RES and the EVs, battery charging strategies in different system operation, the technical and economic challenge of adaptive control algorithms in frequency regulation. In frequency regulation, there are three layers of control: primary, secondary, and tertiary frequency regulation [24]. EVs can simulate the generator droop characteristic to perform primary frequency regulation, and achieve secondary frequency regulation based on area control error (ACE). Tertiary frequency modulation can be achieved based on economic dispatch. A. Primal Frequency Regulation In micro grids, a power disturbance would result in a significant oscillation of frequency due to lack of enough generation resources and spinning reserves. EVs connected to the grid can inject power into the grid, which not only benefits to the frequency stability, but also increases robustness of operation, especially in isolation system. EVs can be considered as new resources in primary frequency control owing to their fast response to disturbances [25]. These studies make the V2G more noticeable than ever in primary frequency control. In primary frequency control, there are two loops: the droop control that reduces the traditional generators, which can cut the fossils consumption, the inertial control that simulates the behavior of conventional generator. Figure 2. Schematic diagram of primary frequency regulation Those control schemes autonomously respond to frequency deviation. Compared the EV as a regular and controllable load in primary control the effects of EVs as controllable load in primary frequency control and battery SOC could be introduced. In figure 2, the balance point will change from a to c when the system load increase without EV, however, the balance point will change from a to b with reasonable charging and discharging maneuvers. The frequency deviation will decrease. B. Secondary Frequency Regulation As a centerpiece of secondary frequency control, AGC is an important control technology for keeping frequency stability. If EVs participate in dispatching load, AGC would respond to frequency deviation both on generation and load side simultaneously, to offset response characteristic insufficiency of traditional generating unit. The feasible and potential AGC operation with EVs was analyzed in [26]. A methodology to make EV participation in AGC in bulk power system was designed in [27]. These studies make EVs have the ability to assist AGC. At present, the studies of AGC with EV are still in initial stages, and mainly focus on EV energy storage to reduce the cost of the battery [27-30]. Some scholar’s studies simulation of AGC with EV energy storage. These results showed that EVs can effectively reduce the ACE and tie-line flow deviation and lower the frequency modulation capacity. 6 Figure 3. Schematic diagram of secondary frequency regulation C. Tertiary Frequency Regulation EVs participated in tertiary control based on economic dispatch. The economic dispatch is an essential issue in smart grid operation and management. In [31], it used stochastic dynamic programming method to optimize EV charging and frequency regulation decision. The economic dispatch model was established in [32]. The results indicated that the EVs plug-in grid could reduce the gap between demand and supply in different periods of time with optimal dispatch schedule. Figure 5. Power grid model for calculating frequency of Japanese system In figure 5, it added EV1 pool and EV2 pool to the gridA, PHV1 pool to the grid-B, with the fluctuation of renewable energy source, the frequency deviation are severe from the figure 6(d) and (f). D. Related Research Paper on Frequency Regulation [33] Figure 6. Simulation results of V2G control and smart charging mode (a) V2G power output of EV1. (b) V2G power output of EV2. (c) V2G power output of PHV1. (d) Frequency deviation in grid-A. (e) Frequency deviation in grid-B. Figure 4. V2G control and smart charging with droop against frequency deviation In [33] wrote by Ota, it proposed V2G control scheme to provide a distributed spinning reserve for the fluctuation of renewable energy source and stabilize the system frequency. Meanwhile, by considering the charging service to EV driver, the paper proposed a smart charging control; this control has a charging offset of half the maximum V2G power (Pmax) and a half droop gain against the frequency deviation. It applied this method to investigate a Japanese 50 HZ system. When EV1 is plugged into the grid at 2 hours, it began to charge with SC mode, and then it compensated the frequency deviation with V2G control. Therefore, the root mean square value of the frequency deviation of grid A changed from 0.0288 to 0.0176. Then it began to charge with V2G control, the frequency deviation kept decreasing, from 0.0176 to 0.0169. Finally, EV1 began to charge with SC mode and ended at 9.8 h. In [33], the proposed V2G control is effective for a distributed spinning reserve. In addition, the proposed smart charging control satisfies the scheduled charging by the 7 vehicle user. The combined control scheme of the V2G and smart charging contribute to reduce the frequency deviation of power grid and compensate the fluctuation of the large-scale integration of intermittent renewable energy sources. VIII. REFERENCES [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] [17] [18] [19] [20] [21] [22] [23] [24] [25] [26] Wikipedia, "History of the Electric Vehicle," [Online]. Available: http://en.wikipedia.org/wiki/History_of_the_electric_vehicle. [Accessed 9 November 2014]. M. Brain, "Electric-car Motors and Batteries - HowStuffWorks," HowStuffWorks.com, 27 March 2002. [Online]. Available: http://auto.howstuffworks.com/electric-car3.htm. [Accessed 8 November 2014]. C. C. Cromer, "automobile -- Encyclopedia Britannica," Encyclopedia Britannica, 27 August 2013. [Online]. Available: http://www.britannica.com/EBchecked/topic/44957/automobile/259061/ Early-electric-automobiles#ref=ref918099. [Accessed 8 November 2014]. http://www.epa.gov/cleanenergy/energy-resources/refs.html http://www.teslamotors.com http://en.wikipedia.org/wiki/Nissan_Leaf http://en.wikipedia.org/wiki/Fossil-fuel_power_station http://www.edmunds.com/fuel-economy/what-happens-to-ev-andhybridhttps://www.fhwa.dot.gov/ohim/onh00/bar8.htmes.html http://www.afdc.energy.gov/fuels/electricity_locations.html http://www.teslamotors.com/supercharger EV Everywhere Grand Challenge. (2014). The Road to Success [online]. Available FTP: energy.gov Directory: http://energy.gov/sites/prod/files/2014/02/f8/eveverywhere_road_to_suc cess.pdf File: PDF Research and Development of Electricity as Vehicle Fuel. Alternative Fuels Data Center, [online] 9/25/13, http://www.afdc.energy.gov/fuels/electricity_research.html, (Accessed: 11/1/14) Lithium-sulfur battery. Wikipedia, [online] 10/29/14, http://en.wikipedia.org/wiki/Lithium%E2%80%93sulfur_battery, (Accessed: 11/1/14) Electrical Machines. Vehicle Technologies Office, [online], http://energy.gov/eere/vehicles/vehicle-technologies-office-electricalmachines, (Accessed: 11/1/14) Advanced Power Electronics: Components and System. National Renewable Energy Laboratory, [online] 11/14/09, http://www.nrel.gov/vehiclesandfuels/powerelectronics/components_sys tems.html, (Accessed: 11/1/14) Power Electronics. Vehicle Technologies Office, [online], http://energy.gov/eere/vehicles/vehicle-technologies-office-powerelectronics, (Accessed: 11/1/14) Plugin Electric Vehicle Infrastructure: A Foundation for Electrified Transport. National Renewable Energy Laboratory, [online] 4/8/10, http://www.nrel.gov/docs/fy10osti/47951.pdf, (Accessed: 11/1/14) http://en.wikipedia.org/wiki/Tesla_Motors http://www.teslamotors.com http://en.wikipedia.org/wiki/Chevrolet_Volt http://www.wired.com/2010/11/chevy-volt-king-of-software-cars/ C. Guille and G. Gross. “A conceptual framework for the vehicle-to-grid (V2G) implementation,”Energy Policy, vol. 37, no. 11, pp. 4379–4390, Jun. 2009. W.Q. Tian, J.H. He, L.Y. Niu, W.G. Zhang, X.J. Wang, Z.Q. Bo, “Simulation of vehicle-to-grid (V2G) on power system frequency control,” in proc. IEEE PEST Innovative Smart Grid Tech.Conf.,Tianjin, pp.1-4, Aug. 2012. P.T. Baboli, M.P. Moghaddam, F. Fallahi, “Utilizing electric vehicles on primary frequency control in smart power grids,”in proc. IPCBEE Petroleum and sustainable development Conf., Singapore, pp.6-10, May. 2011. W. Kempton, J. Tomic, S. Letendre, A. Brooks, T. Lipman. (2001, Jun.),”Vehicle to grid power: battery, hybrid, and fuel Cell vehicles as resources for distributed electric power in California,” UC Davis., California, CA (Online). Available: http://www.its.ucdavis.edu/publication.html [27] P.M.R. Almeida, J.A.P. Lopes, F.J. Soares, M.H. Vasconcelos, “Automatic generation control operation with electric vehicles,” in proc. 2010 IREP Symposium, Rio de Janeiro, pp.1-7, Apr. 2010. [28] J.A P. Lopes, P.M. Lopes, R. AlmediaˈF.J, Soares, “Using vehicle-togrid to maximize the integration of intermittent renewable energy resource in islanded electric grids,” in proc. ICCEP International conference on clean electrical power renewable energy resources impact, Trondheim, pp. 9-11, Jun. 2009. [29] S K. Mullen,“Plugin hybrid electric vehicles as a source of distributed frequency regulation,” Ph.D. dissertation, U.S., Univ. Minnesota, 2009. [30] J.R. Pillai., “Electric vehicle based battery storages for large scale wind power integration in Denmark,” Ph.D. dissertation, Denmark, Univ. Aalborg, 2010. [31] J. Donadee, M. Llic, “Stochastic co-optimization of charing and frequencyregulation by electric vehicles,” in proc. North American Power Symposium Conf., Champaign, IL. pp. 1-6, May.2012. [32] J. Donadee, M. Llic, “Stochastic cooptimization of charging and frequency regulation by electric vehicles,” in proc. North American Power Symposium Conf., Champaign, IL. pp. 1-6, May.2012. [33] Yutaka Ota, Haruhito Taniguchi, Tatsuhito Nakajima, et al, “Autonomous Distributed V2G (Vehicle-to-Grid) Satisfying Scheduled Charging,” IEEE Trans. Smart Grid, vol. 1, no. 1, pp. 559-564, Mar. 2012.