Equipment Suitable for Steeper Slopes

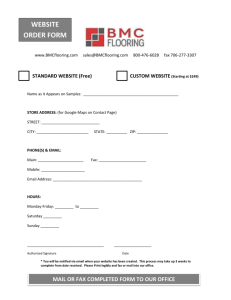

advertisement