Biomechanical Analysis of Grubbing Technique in the Use of Fire Hand Tools

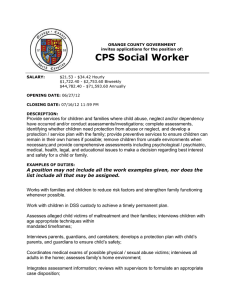

advertisement