Perspectives on: Chromatography as an Integrated Process Al Williams:

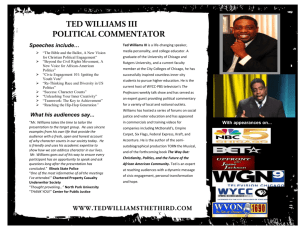

advertisement

Perspectives on: Chromatography as an Integrated Process Al Williams: Applications Manager GE Bioscience Williams; November 2006 Williams; November 2006 Large Scale Planning Plant Design Facility drawing – 3D Williams; November 2006 Suite Design General layout Buffer tank outside clean room System In-line dilution ≥ 1,5 * column diameter System In-line dilution System In-line dilution D D O O Maintenance area Column 2m Crane Column < 1m Column < 1m O R R Pack station Transfer panel Feed tank Williams; November 2006 O Pack station Detail Oriented Williams; November 2006 Ergonomics & Work Flow • • • • EHS, Safety FDA/EPA/OSHA///// compliance SOP Writing Validation Master Plan Williams; November 2006 The True Challange Williams; November 2006 Selectivity Resolution = Efficiency Williams; November 2006 Selectivity: Peak Position Williams; November 2006 Efficiency 0 0 Williams; November 2006 200 20 400 40 60 Time (min) 600 80 Efficiency: Peak Width Efficiency is a measure of the peak width - W1/2 Concentration N = 5.54 (Vr/ W1/2)2 N = Plates N/L = Plates / Meter H = HETP = Meters/Plate Hred = Beads / Plate 100% Max W1/2 50% Max Williams; November 2006 Time/Volume Vr Efficiency Asymmetry Good Asymmetry low selectivity high efficiency low efficiency high selectivity high efficiency low efficiency Williams; November 2006 Poor Asymmetry Column Edge Seal Designs Williams; November 2006 Bu The Problem in Designing Chromatography Processes Pr ? le mp Sa rs ffe nk a T Meth yo a L ? t u P ack Pu s? p m ess ure ? s? od ? w F lo + Column Williams; November 2006 = + Media ? Operator ? Result What Do We Need? • • • • • Basic Knowledge of Application Reasonable Expectation Knowledge of the Media Packing Method Test Method • Equipment Expectations Williams; November 2006 Constant Pressure or Constant Flow Packing Methods Add Slurry Compress Set Adaptor Start Flow Consolidate 3 2 1 Williams; November 2006 During the Pack • Settling • Convective Force • Viscous Drag Williams; November 2006 Determine Pressure Flow Profiles Flow Flow Flow Flow bkc Bed Height Velocity Williams; November 2006 Pressure Determine Pack & Run Regimes Determine the Compression Factor (Cf) = Vgs / Vc Vcrit Packing Velocity Packing Pressure Velocity V gs Run Run Bed Volume Gap Vc Williams; November 2006 ∆P ∆P max Facility Design Criteria From Pressure Flow Data • Pump/Drain Size • Piping/Tank Sizes • Column Specifications Williams; November 2006 • WorkFlow/Ergonomics • Weight issues • Material Handling Issues • Spare Parts Storage Optimize Compression Factor HETP Af 1.20 Velocity Williams; November 2006 1.10 1.15 Pressure 1.25 Examine Wall Effects at L • Pressure/flow curves in columns with different diameters 80 bkc I.D. cm 10 Velocity (cm/h) 70 60 20 30 40 60 80 100 50 40 30 20 10 Unstable 0 0 1 2 3 4 5 Pressure (bar) See: Stickel, J. & Fotopoulos, A., Biotechnol. Prog 2001, 17, 744 - 51. Williams; November 2006 6 Wall Effects None Large Small Williams; November 2006 Wall Effects 1000 Bead Widths Williams; November 2006 Stickel Model Stickel J. & Fotopoulos A, Biotechnol. Prog 2001, 17, 744-751 Stickel Plot for Q Sepharose Big Beads 200000 160000 µ critLo 120000 80000 40000 y = 4901.5x + 33055 Cf = 1.14 0 Williams; November 2006 0 5 10 15 Lo/D 20 25 30 Now and in the Near future Sepharose™ 4 Fast Flow (High porosity) MPa Sepharose 6 Fast Flow (Medium porosity) 8.0 7.0 6.0 5.0 4.0 3.0 2.0 1.0 0.0 Increasing flow rate Williams; November 2006 Other Facility Concerns • • • • • • Packing and or Unpacking Tanks Media; Batch Tailing & Used Storage IBC For Used resin and Tailings Cleaning IBCs, Washer Compatibility Resin Lifetime Disposal Williams; November 2006 Avoid System Effects • • • • • External Volumes Vext Gradient Delay Volume Mixing Efficiency Wall Effects System Pressures Williams; November 2006 Gradient Types %B Continuous gradient Step gradient Complex gradient Volume Williams; November 2006 Gradient Shape / Volume Effects AU %B 1 3 4 5 2 AU 7 6 %B 1 7 2 AU 3 4 5 6 %B 1 2 3+4 5+6 7 Column volume Williams; November 2006 Effects of Gradient Slope • Decreasing Slope – Increases Peak Volume – Decreases Retention Volume – Increases Resolution – Increases Time • Selectivity Increases • Efficiency Decreases Williams; November 2006 • Increasing Slope – Decreases Peak Volume – Increases Retention Volume – Decrease Resolution – Decreases Time • Selectivity Decreases • Efficiency Increases External Volume (Vext) A B Product SAMPLE Williams; November 2006 Monitors Waste External Volume Effects SP Sepharose HP I.D.= 2.6 cm, L= 17 cm 20000 18000 Pre-Column Efficincy (N/m) 16000 Plug Top Post Column Plug Bottom RTD TOP 14000 "RTD Bottom 12000 10000 8000 6000 4000 2000 0 0 2 3 4 Vext (%Vc) Williams; November 2006 5 10 15 Gradient Delay Volume A B S Williams; November 2006 Monitors System Wall Effects Step Pulse Williams; November 2006 System Effects 100 % B 100 % A Volume Williams; November 2006 Asymmetric Mixing Effects Mixer or Air Trap A F/ µ t Τ Î ∆Ρ Vext Vg B S Williams; November 2006 Monitors System Effects Symmetric Williams; November 2006 Asymmetric Well Designed Response Williams; November 2006 Other System Effects • Flow Deviations – Pulsation – Siphoning • Inlet Pressure Changes • Outlet Pressure Changes Williams; November 2006 Designing To System Effects • • • • • • • Keep Vext and Vg << Vc Properly Size Mixers and Air Traps Keep Piping Runs Short Avoid Unnecessary Plumbing Keep Post Column Pressures Low Use Proper I.D. & Keep I.D. Constant Use Pre-column Feedback Controls Williams; November 2006 Distribution Effects Wall Effect Jetting Williams; November 2006 Bubbles Even Distribution Effects Williams; November 2006 2003 Lab Visit & Dye Test MPLC1600 HP Base Matrix L=15 Amgen Methodology Williams; November 2006 2003 Lab Visit & Dye Test MPLC1600 HP Base Matrix L=15 Our Methodology Williams; November 2006 2003 Lab Visit & Dye Test MPLC1600 HP Base Matrix L=15 Wall Effect Williams; November 2006 Screen Retainer Bolts Good Distribution Systems • Asymmetry independent of Vs • Asymmetry independent of Flow / ∆P Williams; November 2006 Examine Test Conditions Distribution Analysis Van Deemter Analysis 5600 1.5 5400 7000 1.5 1.4 1.4 6500 4800 Efficiency Efficiency 5000 Asymmetry Asymmetry 5200 1.3 6000 1.2 5500 1.1 1.3 1.2 1.1 4600 5000 1 1 4400 0.9 4200 4000 0.8 5 15 25 Velocity Williams; November 2006 35 45 55 4500 0.9 4000 0.8 0 0.5 1 1.5 2 2.5 3 Sample Volume (%Vc) 3.5 Distribution Analysis 1.5 End Cell Volume 1.4 6500 1.3 6000 1.2 5500 1.1 5000 1 4500 0.9 4000 0.8 0 0.5 1 1.5 Vs (%Vc) Williams; November 2006 2 2.5 3 3.5 Asymmetry Efficiency (N/L) 7000 Distribution Effects Van Deemter Analysis 5600 1.5 1.4 5200 1.3 5000 1.2 4800 1.1 4600 1 4400 0.9 4200 4000 0.8 5 Williams; November 2006 15 25 35 Velocity (cm/h) 45 55 Asymmetry Efficiency (N/L) 5400 Distribution Analysis Sepharose HP L=15 cm w/ NaCl 7000 2.2 6000 2 5000 1.8 N/m 1.6 As 4000 1.4 3000 1.2 2000 1 0 Williams; November 2006 5 10 Sample Volume (% of Cv) 15 Af N/m 1M ID Column Distribution Effects Van Deemter Analysis 1.8 5600 Prototype 5400 1.6 5000 1.4 4800 1.2 4600 4400 1 4200 0.8 4000 5 Williams; November 2006 15 25 35 Velocity (cm/h) 45 55 Asymmetry Efficiency (N/L) 5200 Distribution Effects Williams; November 2006 Q Sepharose 6 FF, I.D. 100 cm, L=20 cm Sample Blue Dextran 1 mg/ml, Vs= 0.5L CFV 1000 Dye Test • • • • • • • • • Superdex 200 PG N/L = 10,000 Af = 1.45 CF = 1.16 L = 30 Vc= 236L Flow 16 cm/hr Sample: 1 mg/ml Phenol red in 10 mm NaOH Mobile Phase 10 mM NaOH 100 mM NaCl Vs = 1% Vc 5 injects 50 L apart via Index Column as Superloop Williams; November 2006 Harvesting The Bed 1 • Pump off Top Adaptor – Close MPb – Flow in MPt Williams; November 2006 Harvesting The Bed 2 • Suck Off Excess Liquid From Bed with Pack Station Williams; November 2006 Top of the Bed • Bed Expanded to 31.5 cm • Last inject tailing to surface • Non Specific Absorbtion on Top Williams; November 2006 Non Uniform Axial Expansion of Bed 5 4 3 2 1 Williams; November 2006 Harvesting The Bed 3 • Excavate sides • Remove Tube Williams; November 2006 Cross Section • Bed shaped about 20 cm from each outer edge Williams; November 2006 Cross Section • Bed Exposed to 28 cm from each outer edge Williams; November 2006 Harvesting the bed 4 • Bed Reflected @ 8 cm from Center • Bed Reflected @ 6 cm from Center Williams; November 2006 Harvesting The Bed 5 • 4 cm from center • 2 cm from center Williams; November 2006 Harvesting The Bed 6 • 1 cm from center • Center Williams; November 2006 Harvesting The Bed 7 • Clear Zone About 4 cm in diameter 2 cm high Williams; November 2006 Think Now; Column & System • Pulse or Breakthrough • Inline Dilution – Reduce tank or bag size Facility Space – Reduce Number of Buffers – Reduce QC QA and prep time Costs • Risks to Process – Not Precise – Not Accurate – Must Validate Williams; November 2006 Continuous Just-in-time Buffer Preparation Benefits •Eliminate buffer storage vessels -free up valuable real estate -reduce capital and equipment maintenance costs •Automated and controlled blending -reduce buffer preparation time -record and log all parameters with the production run data -reduce QC testing -scalable, consistent performance Williams; November 2006 Just-in-time Buffer Blending and Dilution Systems Set Gradient Criteria to Application Prove performance -accuracy -time to reach set point -scalable -dilution Williams; November 2006 +/- 1% <30 seconds (waste) mls/minute to hundreds of liters/min up to 20X Just-in-time Buffer Blending and Dilution Systems • • Programming Control & Operation: – Recipe built into the chromatography system -Mixing parameters are programmed as part of the chromatography run -Buffers are mixed in line and arrive at the column ‘Just-In-Time’ Williams; November 2006 Just-in-time Buffer Blending and Dilution Systems • EQUIPMENT DESIGN • -2 pumps for dilution only • -3 pumps for simultaneous gradient and/or dilution • Switch Valve Based Systems • Pressure / Flow Feed Back Controlled Metering Valves • Other mixed technologies Williams; November 2006 Just-in-time Buffer Blending and Dilution Systems • CONTROL METHOD • Flow Control OR -One flow meter per pump meters -Mixing control based on flow Williams; November 2006 Flow-Conductivity Control -One conductivity monitor and one or more flow -Mixing control based primarily on conductivity Williams; November 2006 Williams; November 2006 Dilution test Apr 19, 2006 Test 1000 l/h Ratio 5.0 4.0 UV compensated Dilution and Gradient Grad Setp Calc Read Eq % Error Read Eq % Error 5% 0.0208 0.0214 5.16% 0.16% 0.0211 0.0214 5.06% 0.06% 10% 0.0415 0.0424 10.22% 0.22% 0.0423 0.0424 10.03% 0.03% 25% 0.1038 0.1066 25.68% 0.68% 0.1057 0.1066 25.22% 0.22% 50% 0.2075 0.2123 51.15% 1.15% 0.2114 0.2123 50.22% 0.22% 75% 0.3113 0.3176 76.52% 1.52% 0.3170 0.3176 75.14% 0.14% 90% 0.3735 0.3809 91.77% 1.77% 0.3804 0.3809 90.11% 0.11% 95% 0.3943 0.4014 96.71% 1.71% 0.4016 0.4014 94.96% -0.04% 100% 0.4151 0.4227 101.84% 1.84% 0.4227 0.4227 100.00 % 0.00% UV max peak 2.07525 calculated from the 60% point got from the UV linearity test done Apr18, 2006 (60% values)/0.6 Williams; November 2006 Calc Dilution test Apr 18, 2006 Test performed 300 l/h Ratio 5.0 4.0 Dilution and Gradient Grad Setp Calc Read UV compensated Eq % Error Calc Read Eq % Error 5% 0.0208 0.0227 5.47% 0.47% 0.0210 0.0227 5.39% 0.39% 10% 0.0415 0.0442 10.65% 0.65% 0.0421 0.0442 10.50% 0.50% 25% 0.1038 0.1085 26.14% 1.14% 0.1052 0.1085 25.78% 0.78% 50% 0.2075 0.2149 51.78% 1.78% 0.2105 0.2149 51.06% 1.06% 75% 0.3113 0.3194 76.95% 1.95% 0.3157 0.3194 75.89% 0.89% 90% 0.3735 0.3805 91.68% 1.68% 0.3788 0.3805 90.40% 0.40% 95% 0.3943 0.4006 96.52% 1.52% 0.3999 0.4006 95.18% 0.18% 100% 0.4151 0.4209 101.41% 1.41% 0.4209 0.4209 100.00% 0.00% UV max peak 2.07525 calculated from the 60% point got from the UV linearity test done Apr18, 2006 (60% values)/0.6 Williams; November 2006 Variables To Consider • • • • 2 Pump Dilution System....7000 LPH Williams; November 2006 Viscosity Temperature Miscible/Gas Usable Flow Rate Range • Inlet /Outlet Pressure Effects • Stock Solution Reproducibility Just-in-time Buffer Dilution Conductivity Feedback Control Error = +/- .01% Buffer A: Buffer B: Calculated values Example: 10% solution value = (29.6)(10%) Equivalent % = Williams; November 2006 Read Value Calculated 100% DI Water NaCl at 29.6 mS/cm Large media handling Concept description 9 Media shipped either in standard pack size or in column equivalent volume 9 Tools for removing ethanol 9 Tools incl. methods for fast and easy remixing of chromatographic resin 9 Convenient transfer to feed tank 9 Easy packing of column via automated pack station Williams; November 2006 Large media handling Solutions – shipping containers Williams; November 2006 Large media handling Solutions – stirrer stand Williams; November 2006 Large media handling Solutions – media wand Williams; November 2006 Large media handling Solutions – feed tank Williams; November 2006 Ethanol Calcs for Virgin Resin • For Agarose based Media From GE – Slurry% as Supplied = 70 – % Ethanol as Supplied = 18 – 20% – Matrix Volume = 8 – 10% – Targeted Overage of Fill = 2% – Nominal Media Volume = Vgs Williams; November 2006 How Much Ethanol as supplied 5 L Container Vgs = 5 x 1.02 = 5.1L as a 70% Slurry Matrix Volume = Vgs x 0.1 = 0.51L Vt = (5.1 / .7 ) - 0.51 = 7.3 – 0.51 L = 6.8L Volume Ethanol = 6.8 L x .2 = 1.36L Gallon Proof = 1.36 L / 3.85 L/g = .35 or ca, 0.7 Gallon Proof / L media supplied Williams; November 2006 Decanting Removes ? • 5L Container Vt = 7.3 L Vgs = 5.1 L Decantation removes = 7.3 – 5.1 = 2.2 L 2.2 L @ 20% = 0.44 L @ 100% Ethanol 0.44 / 1.36 ~ 32% removed Refill with WFI to same level = 14% Ethanol Williams; November 2006