Optimum Power and Ratios for Liquefied Petroleum Gases Economy Air-fuel

advertisement

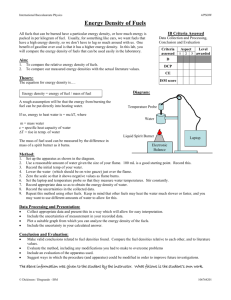

OREGON \\o. V)- OCT '-- _i COLLECThy Optimum Power and Economy Air-fuel Ratios for Liquefied Petroleum Gases By W. H. PAUL and M. N. POPOVICH Bulletin Series, June 1941 Engineering Experiment Station Oregon State System of Higher Education Oregon State College THE Oregon State Engineering Experiment Station was established by act of the Board of Regents of the College on May 4, 1927. It is the purpose of the Station to serve the state in a manner broadly outlined by the following policy: (1)To stimulate and elevate engineering education by developing the research spirit in faculty and students. (2) To serve the industries, utilities, professional engineers, public departments, and engineering teachers by making investigations of interest to them. (3) To publish and distribute by bulletins, circulars, and technical articles in periodicals the results of such studies, surveys, tests, investigations, and researches as will be of greatest benefit to the people of Oregon, and particularly to the state's industries, utilities, and professional engineers. To make available the results of the investigations con ducted by the Station three types of publications are issued. These are: (1) Bulletins covering original investigations. (2) Circulars giving compilations of useful data. (3) Reprints giving more general distribution to scientific papers or reports previously published elsewhere, as for example, in the proceedings of professional societies. Single copies of publications are sent free on request to residents of Oregon, to libraries, and to other experiment stations exchanging publications. As long as available, additional copies, or copies to others, are sent at prices covering cost of printing. The price of this bulletin is 25 cents. For copies of publications or for other information address Oregon State Engineering Experiment Station, Corvallis, Oregon Optimum Power and Economy Air-fuel Ratios for Liquefied Petroleum Gases W. H. PAUL Associate Professor of Mechanical Engineering and M. N. Por'ovlcH Graduate Assistant in Mechanical Engineering Bulletin Series, No. 14 June 1941 Engineering Experiment Station Oregon State System of Higher Education Oregon State College TABLE OF CONTENTS Page I. Acknowledgments and Summary ---------------------------------------------------------------------3 1. 2. II. Acknowledgments ------------------------------------------------------------------------------------ 3 Summary -----------------------------------------------------------------------------------------------------3 Introduction ---------------------------------------------------------------------------------------------------------- 4 1. Reasons for the Investigation ---------------------------------------------------------------- 4 2. Specific Requirements of a Fuel for Internal-Combustion Engines---------------------------------------------------------------------------------------------------- 4 3. General Requirements of a Fuel for Internal-Combustion Engines----------------------------------------------------------------------------------------------------- III. Properties of Paraffin Hydrocarbons ------------------------------------------------------------- 1. Molecular-Structure and Properties ----------------------------------------------------- 2. Octane Ratings of the Fuels Used ------------------------------------------------------ 8 IV. Method of Conducting Tests ---------------------------------------------------------------------------- 9 General Equipment ---------------------------------------------------------------------------------- 9 Procedure -------------------------------------------------------------------------------------------------Results ------------------------------------------------------------------------------------------------------------------ 11 1. 2. V. 11 1. Power and Economy Curves ---------------------------------------------------------------- 11 2. Effect of Molecular Size on Optimum Air-Fuel Ratios 3. ---------------- 11 Air-Fuel Ratio Meter Calibration Curve ------------------------------------------ 15 4. Operating Principle of Thermal-Conductivity Instrument ---------- 15 5. Discussion of Instrument Calibration -------------------------------------------------- 16 6. Explanation of Meter Inaccuracy in the Lean Range VI. VII. Conclusions References ------------------ 16 ---------------------------------------------------------------------------------------------------------- 18 ------------------------------------------------------------------------------------------------------------ 19 ILLUSTRATIONS Figure 1. Figure 2. Figure 3. Figure 4. Figure 5. General View of Apparatus ---------------------------------------------------------------------- 9 Thermal-Conductivity Type Air-Fuel Ratio Instrument ------------------ 10 Optimum Power Air-Fuel Ratios for All Fuels Investigated -------- 12 Optimum Economy Air-Fuel Ratios for All Fuels investigated 12 Optimum Air-Fuel Ratios vs. Per Cent Carbon Contained . byEach Fuel ------------------------------------------------------------------------------------------ 13 Figure 6. Calibration of Thermal Conductivity Type Air-Fuel Ratio Instrument for the Various Fuels 14 TABLES Table 1. Boiling Points and Octane Ratings of Hydrocarbons ------------------------ 6 Table 2. Constants of Liquefied Petroleum Gases ---------------------------------------------- 8 Table 3. Optimum Power and Economy Air-Fuel Ratios for Various Hydrocarbon Fuels 15 Table 4. Thermal Conductivities of Various Exhaust Gases ---------------------------- 16 Table 5. Typical Exhaust-Gas Analyses for Selected Air-Fuel Ratios ---------- 17 Optimum Power and Economy Air-fuel Ratios for Liquefied Petroleum Gases By W. H. PAUL Associate Professor of Mechanical Engineering and M. N. PoPovicH Graduate Assistant in Mechanical Engineering I. ACKNOWLEDGMENTS AND SUMMARY 1. Acknowledgments. The authors are grateful to the American Liquid Gas Corporation of Los Angeles, California, for supplying fuel conversion equipment; to the Standard Oil Company of California for furnishing the special hydrocarbon fuels used in the investigation; to the Electro-Products Company of New York for air-fuel ratio instruments; to Harold A. Marble, senior student in Mechanical Engineering, who gave valuable aid in assisting with tests; and to Professor S. H. Graf, Director of Engineering Research and Head of Mechanical Engineering, for suggestions and editorial counsel. 2. Summary. This investigation includes the determination of optimum power and economy air-fuel ratios for propane, n-butane, iso-pentane, isooctane, gasoline, and commercial mixtures of butane and propane. It also includes calibration of a commercial thermal conductivity type air-fuel ratio instrument for each of these fuels. Explanation is offered for the unreliability of such instruments in the lean-mixture range. During the past few years utilization of liquefied petroleum gases in internal-combustion engines has undergone considerable expansion. The lighter hydrocarbons, particularly propane and butane, have certain desirable characteristics that make them attractive as fuels for the carburetting engine. Among these are high resistance to detonation, uniform manifold distribution, absence of impurities, and low cost under certain favorable conditions. This study was carried out by using a single-cylinder, water-cooled engine of the four-stroke cycle type. A d-c generator formed an integral part of the unit, and power measurements were made with suitable electrical instruments. Air was metered accurately through a large "wet" type gas meter, while the fuel quantities were determined by weighing. The liquid fuels, confined under pressure in tanks, were converted to gases and reduced in pressure by means of special apparatus obtainable commercially. Air-fuel ratio readings were indicated by a thermal-conductivity type instrument connected to the engine exhaust. 4 ENGINEERING EXPERIMENT STATION BULLETIN No. 14 In addition to test results, the effect of size and shape of fuel molecules on the knock resistance of paraffinic hydrocarbons is discussed. Suggestions for the proper carburetion of the liquefied petroleum fuels are given. Calibration of the air-fuel ratio instrument for the lighter fuels is pre- sented and an explanation is offered for the difference between indicated instrument readings and the true values of air-fuel ratio. Explanation is also given for the fact that thermal-conductivity type meters swing back toward richer readings when mixtures are very lean. The investigation showed that the air-fuel ratios for maximum power and maximum economy for liquefied petroleum fuels were considerably higher than for gasoline. In general, fuels having smaller molecules yielded higher air-fuel ratios for maximum power. These air-fuel ratios more nearly approached calculated values for perfect combustion. II. INTRODUCTION 1. Reasons for the investigation. Little has been written on the subject of experimentally determined air-fuel ratios for maximum power and maximum economy for fuels other than gasoline. For gasoline, writers report values ranging from 12.5 to 13.5 pounds of air per pound of fuel; this lack of agreement depending upon the operating conditions and characteristics of the engine used. For other fuels, however, only calculated, theoretical air requirements are generally cited: The theoretical air-fuel ratio for gasoline, the formula for which is usually taken as pure octane, CH,8, is 15.2, which differs materially from the actual values cited above for maximum power. With the growing use of liquefied petroleum gases as motor fuels there is need for accurate knowledge of these specific air-fuel ratio quantities for each fuel and some of their blends. Iso-pentane, iso-octane, and gasoline were included along with butane and propane in the present investigation in order to obtain a more complete range of data for general comparison of actual with theoretical values for the paraffinic hydrocarbon series. Commercial mixtures of 60-40 butane-propane and 70-30 butane-propane were included because these fuels are sold as commercial mixtures. Along with increased use of these liquefied petroleum gases has come some demand for air-fuel ratio instruments calibrated for these fuels. If optimum conditions are determined by a test and the air-fuel meters are calibrated for these fuels, their range of use will be extended and the fuels can be utilized with greater efficiency. With this in view it was the purpose of this work to determine the air-fuel ratios for maximum power and maximum economy for a range of paraffinic hydrocarbon fuels between propane and iso-octane, together with combinations, and to calibrate a commonly used type of air-fuel ratio meter for these fuels. 2. Specific requirements of a fuel for internal combustion engines. The four most desirable characteristics of a fuel for internal combustion engines are recognized as high resistance to detonation, suitable volatility for good manifold distribution, low sulphur content, and minimum tendency toward gum formation. The liquefied petroleum fuels have a higher detonation resistance than all but the most expensive aviation fuels. In the matter of cylinder and mani- fold distribution, gaseous fuels are superior to liquid fuels because they are completely gasified rather than atomized during carburetion. Due to their gaseous nature, liquefied petroleum fuels contain little or no gum or sulphur, as they are recovered in relatively pure form in the refining process. AIR-FUEl, RATIOS FOR LIQUEFIED PETROI.EUM GASES Although these gaseous fuels contain fewer heat units per gallon, performance and economy can be augmented by increasing the compression ratio of the engine. Possible compression ratios for butane and propane have been reported as 8.5 :1 and 10:1, respectively. The authors have successfully used 9 :1 with butane-propane mixtures. Unless quite expensive or at least quite heavily leaded gasoline is used, the octane numbers of the liquid fuels will not approach those of the gaseous fuels; therefore, compression ratios used with gasoline will be limited in comparison. 3. General requirements of a fuel for internal-combustion engines. A fuel is usually considered as a material that is generally available, is sufficientiv cheap, has heating value, and can be used commercially for its thermal energy. The cost of liquefied petroleum fuels at or near refineries is quite low, being only a fraction of the cost of gasoline. Since the problem of distributing these fuels to points far removed from the source of supply has not yet been worked out to any great extent, the cost per gallon in remote territories is quite high. At present liquefied petroleum gases fail to comply completely with the availability requirement except in localities where they are being manufactured. These fuels are being used at present, however, by commercial vehicles making long trips on routes where supply stations have been established. If the utilization of liquefied petroleum gases expands, as expected, the largest immediate outlet for these fuels will likely be in the heavy-duty motor transport field. Mention may here be made of the fact that iso-butane is now being used with butylene in the alkylation process to manufacture 100 octane aviation gasoline. The amount of butane needed, at present, however, for this use is small compared to the total quantity produced. III. PROPERTIES OF PARAFFIN HYDROCARBONS 1. Molecular-structure and properties. With the exception of gasoline, fuels used in this work were of the paraffinic type, having the general This group, or family of hydrocarbons, is the sochemical formula, all called "saturated" series, and is the predominant hydrocarbon type in gasoline. By "saturated" is meant that each carbon atom in the molecule is completely satisfied with hydrogen. Methane, the first in the series, consists of one atom of carbon and four of hydrogen, and therefore has the formula CH. Following methane in order in the series are: ethane, CH; propane, CHs; butane, CH,0; pentane, CH,; liexane, CH4; heptane, CH,; octane, CH,s; and so on up. H HHHH HCCCCH HHHH I I Molecular structure of nhutane HCH H H HCCCH I III HHH Molecular structure of iso.butane Due to the characteristic structural pattern, shown at the left above, these hydrocarbons are commonly referred to as the open-chain type. Starting with ENGINEERING EXPERIMENT STATION BULLETIN No. 14 6 Table 1. BOILING POINTS AND OCTANE RATINGS OF HYDROCARBONS Hydrocarbon Pare ffins Boiling point F (760 mm) Octane number (CFR-ASTM) -259 110 n-Butane 2-Methyipropane 33 11 92 99 n.TPentane 97 82 49 61 89 83 n.Hexane 156 141 146 121 137 25 73 75 96 95 209 n-Heptane 194 2-Methyihexane 2 2-Dimethylpentane ----------------------------------------- 175 194 2 3-Dimethylpentane 177 2 4-Dimethylpentane 187 3-Dimethylpentane 3 178 3-Trimethylbutane 2 2 45 93 89 82 84 Ethane----------------------------------------------------------------- -127 2-Methylbutane Dimethyipropane 2-Methylpentane 3-Methylpentane 2 2-Dimethylbutane 2 3-Dimethylbutane : : : : 104 100 0 101 n-Octane 3-Methyiheptane 2 3-Dimethylhexane 2 5-Dimethylhexane 4-Dimethyihexane 3 2 2 3-Trimethylpentane 2 2 4-Trimethylpentane 2 3 4-Trimethylpentane 3-Methyl-3-ethylpentane 2 2 3 3-Tetramethylbutane 258 246 240 229 244 230 210 236 245 224 17 n-Nonane 303 45 -152 - 54 97 n-Pentene (-2) 154 n-Hexene (-2) 2.Methylpentene (-2) ------------------------------------------151 154 3-Methylpentene (-2) ---------------------------------------106 2 2-Dimethylbutene (-3) 172 2 2 3-Trimethylbutene 257 n-Octene (-2) 252 3-Methylheptene (-2) 217 2 4 4.Trimethylpentene (-1 and 2) 81 85 80 78 78 79 94 89 55 74 86 : : : : : : : : : Ole/ins : : : Di-O Ic/ins Hexadiene (-2:4) 35 76 52 85 102 100 97 91 103 176 77 -----------------------------------------------139 121 Cyclopentane Methylcyclopentane -------------------------------------------181 Cyclohexane --------------------------------------------------------177 Methylcyclohexane 213 68 83 82 77 71 Naphthenes Ethylcyclobutane A romatics Benzene --------------------------------------------------------------Toluene-------------------------------------------------------------- 176 231 108 104 butane the larger molecules may have different atomic arrangements, yielding compounds of the same chemical formula, but with slightly different properties. There are two butanes, shown on page 5, and three pentanes, and as the number AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES of carbon atoms increases, the number of possible combinations increases rapidly. These iso-paraffins or "isomers" do not vary a great deal from their open-chain contemporaries in the boiling point, vapor pressure, and other general physical properties, but the variation in octane number is marked. For instance in the extreme case of octane, normal-octane has an octane number of 17, but 2-2-4 trimethyl pentane, an isomer, has an octane number of 100. Below are shown the structural configurations of these two octanes. HHH HHHHH HCCCC--CCCCH HHH HHHHH I I I I I I I I I I Octane number, minus 17. Normal-octane. H H H H H HH HCC I -H 1 HC-H I 2.2-4 trimethyl pentane, or iso-octane, an isomer of n-octane. Octane number 100. The Journal of the Institute of Petroleum, June 1940, (1)* shows octane ratings (CFR-ASTM) for a number of hydrocarbons and their isomers. These are tabulated in Table 1. Hydrocarbons in the saturated or paraffinic series become more dense as the number of carbon atoms increases. Methane, CH4, is a gas and at ordinary temperatures cannot be liquefied even at extreme pressures. Ethane, C2H6, can be liquefied at ordinary temperatures, but the pressure requirement is so great that the container would be too heavy to be practical. Propane, C5H5, is a gas at atmospheric pressure, but it can be liquefied at ordinary temperatures by a pressure of about 125 pounds per square inch gage, and is safe in a container of reasonable strength. Normal-butane, C4H,0, boils at 33 F, so in order to keep it in the liquid state, it, too, must be kept under pressure. Normal-pentane, C5H,2, boils at about 97 F and is a very volatile liquid at room temperature. For that reason it is kept in pressure vessels. Normal-hexane, C6H,, is a liquid that boils at 156 F and may be stored in ordinary tanks. Isomers of hexane are a major constituent of gasoline. The lightest hydrocarbon that gasoline contains in any appreciable quantity is butane, the content being as high as 8 per cent in some winter gasolines. Table 2 lists some of the more commonly used properties of propane, normal-butane, and iso-butane. Numbers in parentheses refer to references listed in Section VII. !si7si'$ 8 5i s-vs ii.- - a - e- -. kNGINEERING LXPERIMENT STATION Buu.F-rlN No. 14 Table 2. CONSTANTS or LIQUEFIFD 1'FTROIEUM GASFS (All values not otherwise designated are at 60 F and 30 inches of mercury) Propane Characteristics Chemical formula .............. Molecular weight Percentage composition -. . Normal state at 60 F and 30 inches mercury .... Specific gravity gas (Air=1) ............................... Specific gravity liquid at 60 F/60 F Boiling point liquid: Degrees F ......................... Critical Data: (a) Temperature F pounds (b) Pressure per square inch ... C3H5 CHi.CHCHs Isohutane N-butane CH5 C4H10 CHS.CHS.CHS.CHS CH3.CH: (CH), 44.0624 58.078 58.078 H-18.2977 C-8L7023 H-17.3525 C-82.6475 (H 17.3525 Gas ) C-82.6475 Gas Gas 1.5206 2.0042 2.0042 0.5089 0.5824 0.5665 44 32.9 13.64 206.6 303.4 272.66 648.1 552.4 538.23 192.6 816.3 173.52 841.64 169.92 801.68 Latent heat of vaporization at normal boiling point: Btu per pound Btu per gallon Pounds per gallon of liquid-at 60 F 4.2383 4.718 4.8544 Btu tier cubic foot of vapor at 60 F and 30 inches mercury-dry Btu per pound ................... 2,519 3,274 3,274 21,633 21,331 21,331 Btu tier gallon 91,686 103,465 100,639 Highest useful compres- sion ratio Octane number 10 :1 100 8 :1 9 :1 92 Authority: Handbook of Butane-Propane Gases. Smittenberg, J., JI. Inst. of Pet., 26:294-303, 1940. 2. Octane ratings of the fuels used. The fuels used in this work were commercially pure propane, normal-butane, iso-pentane, iso-octane, butanepropane mixtures, and gasoline. The octane numbers as reported in Table 1 are: Propane............................................................ 100 Normal-butane ---------------------------------------------- 92 Iso-pentane ------------------------------------------------------ 89 Iso-octane -------------------------------------------------------- 100 The gasoline used had an octane rating of 74 (CFR-ASTM). - AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES IV. METHOD OF CONDUCTING TESTS 1. General equipment. The principal equipment used consisted of a Delco engine with integral direct-current generator, an "Algas" fuel converter (universal unit), a drum with rubber heads to dampen intake pulsations, a fuel-weighing system, a meter for measuring air volume, an air-fuel ratio instrument, an accurate chronometric tachometer, and an operating panel equipped with resistors for loading the engine and containing connections for electrical apparatus to measure power output. A general view of the apparatus, exclusive of the air meter and pulsation dampener, is shown in Figure 1. The engine used was a single-cylinder Delco having a bore of 2 inches, a stroke of 5 inches, and a compression ratio of 6.5. It was directly connected to a 32-volt, self-excited, direct-current generator. The cooling system was of the evaporative, water-jacket type, with a reflux condenser to precipitate the steam formed. The ignition system was the battery-distributor type. A neon ignition ring, installed permanently on the engine, indicated the spark timing with the engine operating. GENERAL VIEW OF AFPARATUS. SHOWING, FROM LEFT TO RIGHT, FUEL MEASURING SYSTEM ON TABLE, FUEL CONVERTER ON STAND, ENGINE ON BASE, AND INSTRUMENT PANEL WITH CONTROLS, AT RIGHT. AIR METER AND PULSATION SHOCK ABSORBER NOT Figure 1. SHOWN. Air volume consumed by the engine was measured by means of an American Meter Company "wet" type laboratory test meter having a capacity of one cubic foot per revolution. Between the meter and the engine was placed a 20-gallon drum with the heads removed and replaced with rubber 10 ENGINEERING EXPERIMENT STATION BULLETIN No. 14 sheeting to dampen pulsations caused by the air intake of the engine. This device proved to be very satisfactory. The fuel, in the case of the more volatile hydrocarbons, was held in a small metal cylinder adapted from an oil filter and was directly weighed on a 15pound beam-balance. In operating with butane and propane, the volume of the gasified fuel was measured by a 0.1 cubic foot Sargent wet-test meter, and these volumetric results were checked with values obtained by direct weighing. The liquefied petroleum fuels were gasified by means of an "Algas" conversion unit made by the American Liquid Gas Corporation. This unit consists of a heat exchanger and two diaphram reducing valves, which are connected in series for the purpose of reducing the gas pressure to atmospheric. Control of fuel quantity to the engine is accomplished by means of a valve at the outlet of the conversion unit. The gaseous fuels were introduced into the engine through a hole at the venturi throat of the standard gasoline carburetor. The operating panel contained resistors for loading the engine, switches for starting,, and a field rheostat for controlling generator field current. The panel also contained outlets for voltmeter and ammeter connections used to measure power. A commercial air-fuel ratio instrument of the thermal-conductivity type made by the Electro-Products Company, Figure 2, was used to indicate air-fuel relations. J Ftgure 2. THERMAL-CONDUCTIVITY TY?E AIR-FUEL RATIO INSTRUMENT. AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES 11 2. Procedure. Before each test, the engine was warmed up for a period of about 2 hours in order to establish equilibrium conditions. These equilibrium conditions involved crankcase temperature, generator winding temperature, steady conditions of air and fuel intake, and constant resistor coil temperature. A constant speed was chosen in order to bring oil temperatures to equilibrium and maintain constant engine friction. A speed of 675 revolutions per minute was selected; since, with a heavy load and throttle more than half open, good speed regulation could be maintained by means of the field rheostat. Temperature and quantity of water through the converter heat exchanger were regulated to insure complete evaporation of the fuel without excessive superheating. Prior to any run with a particular fuel the spark timing was set for maximum power with an air-fuel ratio very close to that for maximum output as determined from a short preliminary trial. Inasmuch as flame speed varies with mixture strength, the spark timing should be adjusted for each different air-fuel ratio. In this work, however, the object was to find the air-fuel ratio for maximum power; therefore, the single spark adjustment fulfilled the requirement. At the beginning of each day's operation, the fuel container was filled and tested for leaks, since, on the weight basis, even a very small leak would introduce objectionable error in the results. The beginning of a run was marked by the settling of the scale beam past the midpoint of its swing, at which time a stopwatch was started, and the initial reading on the air meter was observed. In the case where the small 'wet" type meter was used in conjunction with weighing, it was read simultaneously. Readings of power output, air temperature, oil temperature, and speed were made twice during a run. One reading of indicated air-fuel ratio was obtained after the instrument pointer had settled to a fairly constant position. After the consumption of one-tenth pound of fuel, the run was stopped, at which time final readings were taken on the air meter, and the fuel-measuring equipment. The power output, measured air-fuel ratio, and the specific fuel values were calculated and roughly plotted as the test proceeded. A sufficient range of air-fuel ratios on either side of the optimum was investigated to make certain that the optimum point had been found. V. RESULTS 1. Power and economy curves. Curves showing power and economy results have been prepared for each fuel investigated. In the case of the power curves, results for all fuels are plotted in Figure 3, in which per cent of maximum power output is plotted as ordinate, and air-fuel ratio as abscissa. Figure 4 includes the economy curves for all fuels and was constructed with per cent of minimum fuel consumption as ordinate, and air-fuel ratio as abscissa. It can be seen that the range of optimum air-fuel ratio values obtained for the fuels investigated was fairly wide. The air-fuel ratio for maximum power for propane was found to be 15.5, whereas the corresponding figure obtained for gasoline was 13.0. For maximum economy, the range was from 17.9 for propane to 16.0 for gasoline. 2. Effect of molecular size on optimum air-fuel ratios. From the maximum power and maximum economy values obtained for each fuel (Figures 3 and 4), a curve was constructed with these optimum values plotted against the respective carbon contents of the fuel molecules (Figure 5). On this plot are also shown the theoretical air-fuel ratios for the various fuels. Since the carbon content of hydrocarbons in a particular series is proportional to the size !HHH I:: PROPANE 60-40 BUTANE- PROPANE 70-33 BUTANEPROPANE GASOLINE w Q. BC SO-OCTAN ID 0. SO-PENTANE I- D 0 N-BUTANE-- Ui 9 2 4 13 Figure 3. 6 17 16 15 AIR-FUEL RATIO lB LB AIR LB FUEL OPTIMUM POWER AIR-FUEL RATIOS FOR ALL FUELS INVESTIGATED. 120 I0. 115 ______ ______ ______ PROPANE z 0 0 - ______ ______ 60-40 BUTANE-PROPANE -J _N-BUTANE 110 105 IIi CASOLINE ISO-OCTANF U. 0 1 100 _______I5O-PENT6NE z ______ ______ II w U U. 12 13 14 IS 16 AIRFUEL RATIO Figure 4. Il 8 LB AIR LB FUEL OPTIMUM ECONOMY AIR-FUEL RATIOS FOR ALL FUELS INVESTIGATED. 12 19 AIR-FUEl. RATIOS FOR LIQUEFIED PETROLEUM GASES 13 of the molecule, the curves demonstrate the effect of molecular size on optimum air-fuel ratio requirements as well as the effect of size on the relative agreement of actual air-fuel ratios with theoretical values. It can be seen that the points obtained experimentally define the curves quite well, although some deviations are evident. From Figure 5 it is apparent that with decreasing molecular size, or reduc- tion in per cent carbon, the air-fuel ratio for maximum power approaches the theoretical ratio for perfect combustion. Since the fuels showed a general trend toward higher combustion efficiency as the molecule became smaller, it would seem that the actual and theoretical values would practically coincide for ethane and methane, two lighter hydrocarbons not included in this investigation. (9 - - - - - 0 -- (8 --- ECONOMY 2 I- -j Ui - PERFECT COMBUSTION 4 (5 POWER 'IiIIIi 8182838485 PER CENT CARBON OPrIMUM ATR-FSXEL RATIOS VS PER CENT CARBON CONTAINED BY EACH FUEL. POINTS FROM LEFT TO RIGHT IN ORDER REPRESENT PROFANE, 60-40 BUTANE-PROPANE, Figure 5. 70-30 BUTANE-PROPANE, BUTANE, PENTANE, OCTANE, AND GASOLINE. .--., 14 ENGINEERING EXPERIMENT STATION BULLETIN No. 14 It is not expected that results obtained with olefines and other nonparaffinic fuels would fall on these curves, but it is probable they would form curves having the same general shape. The factor controlling the degree to which actual air-fuel ratio values approach theoretical values is likely to be the molecular size rather than per cent carbon. The general shape of the economy curve in Figure 5 is similar to that of the power curve except for being slightly flatter. It was evident that as the fuel molecules became smaller, the per cent excess air, over the theoretical amount for perfect combustion, increased. This is shown by the fact that the ordinate distances between the theoretical and economy curves increased as molecules became smaller. The maximum economy for gasoline occurred about one air-fuel ratio higher than the theoretical value. On the other hand, the maximum point for propane occurred over two air-fuel :ratios above the theoretical value, definitely indicating a greater quantity of excess air in the case of lighter fuels. This would indicate that leaner mixtures should be used with increasingly light fuels to obtain maximum economy conditions. The difference in air-fuel ratio between maximum power and maximum economy for any one fuel was greater in the case of fuels with higher molecular weight, being 3.0 air-fuel ratios for gasoline and 2.4 air-fuel ratios for propane. This increased difference is explained by the fact that gasoline is atomized during carburetion rather than gasified as is propane, and therefore mixing of gasoline and air is not as thorough as the mixing of propane and air. In going from the maximum power point to the maximum economy point, 17 - - - - - - -- - - - -- 0 -- - - GASOLI NE\ 15 2 J7 Ii Q-t77 _13 / / ISO PENTANE c - SPPOPANE 9 10 12 14 16 18 20 MEASURED AIRFUEL RATIO Figure 6. CALIBRATION OF THERMAL CONDUCTIVITY TYPE AIR-FUEL RATIO INSTRUMENT FOR THE VARIOUS FUELS. 4 AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES 15 additional air is introduced until there is an excess. This excess of air causes more turbulence and better atomization of the gasoline, resulting in greater combustion efficiency and a maximum economy point higher than might be expected. The excess air added in going from maximum power to maximum economy has less influence on the smaller molecules, such as propane and butane, since they are completely gaseous and lend themselves more readily to thorough and uniform mixing. Therefore the ordinate difference between the power and economy curves becomes less as the fuels become lighter. For convenient reference in the selection of an optimum point for a particular fuel, the values obtained from Figure 5 for maximum power and economy for the fuels investigated are shown in Table 3. Table 3. OPTIMUM POwER AND ECONOMY AIR-FUEL RATIOS FOR VARIOUS HYDROCARBON FUELS. Fuel Propane----------------------------------------------------------------------60-40 Butane-propane ------------------------------------------------70-30 Butane-propane ------------------------------------------------- n-Butane -------------------------------------------------------------------Iso-pentane ---------------------------------------------------------------Iso-octane ------------------------------------------------------------------- Gasoline--------------------------------------------------------------------- Air-fuel ratio for maximum power 15.5 15.3 15.2 15.0 14.5 13.7 13.0 Air.fuel ratio for maximum economy 17.9 17.8 17.7 17.5 17.2 16.6 16.0 The values tabulated for butane were not in complete agreement with those reported by Vogt (2) in an earlier investigation. Greatest differences from his values were in maximum economy. Maximum economy for any one fuel, however, is largely dependent upon engine characteristics. For comparable air rates in the two investigations maximum power values are in good agreement. 3. Air-fuel ratio meter calibration curve. Although points were somewhat scattered, curves of indicated air-fuel ratio plotted against measured air-fuel ratio, Figure 6, for the fuels investigated, show a definite trend in relation to percentage carbon and hydrogen in the fuel. In order to produce more accurate calibration curves for the air-fuel ratio meter, additional data were used that had been obtained from previous tests made in the Oregon State College automotive laboratory on multi-cylinder engines. Actually the curves are a result of composite runs on both single and multi-cylinder engines, using the same type and make of air-fuel ratio instrument. 4. Operating principle of thermal-conductivity instrument. In order to facilitate understanding of the discussion dealing with air-fuel ratio meter results, a brief description of the operating principle of the thermal-conductivity type of instrument will be reviewed. The fundamental principle of operation deals with the difference in thermal conductivity of the exhaust gas from that of a standard gas. The fact that the thermal conductivity of hydrogen is considerably higher and the thermal conductivity of carbon dioxide is somewhat lower than the conductivity of carbon monoxide, nitrogen, and oxygen, results in definite characteristic changes in thermal conductivity of different exhaustgas samples. The exhaust gas enters a cell containing a coil of resistance wire, which is an arm of a Wheatstone bridge circuit. A second cell, sealed and containing a standard gas, together with a coil of resistance wire, makes up another arm of the Wheatstone bridge circuit. The two remaining resistance 16 ENGINEERING EXPERIMENT STATION BULLETIN No. 14 arms are made equal. A controlled amount of current from a dry-cell battery is passed through the bridge circuit and warms it to equilibrium temperature. In passing exhaust gas of different thermal conductivity from the standard gas through the test arm, difference in cooling of the rcsistance wire in the test cell from the cooling of the resistance wire in the standard cell causes a temperature change that affects the resistance in the test cell and unbalances the bridge. Tins deflects the galvanometer over a scale graduated in air-fuel ratio. It is a known fact that rich mixtures yield exhaust gases of high hydrogen and relatively low carbon (hioxide volumetric percentages, thereby producing a gas of high thermal conductivity (7). Inasmuch as a definite correlation exists between hydrogen content and air-fuel ratio, (3) it is possible to graduate a galvanometer scale in terms of air-fuel ratio. 5. Discussion of instrument calibration. The calibration curves for the air-fuel ratio meter showed a definite trend toward richer readings as the density of the fuels decreased; i.e., the instrument indicated lower and lower readings for a given measured air-fuel ratio. As thc hydrocarbon fuel molecules become smaller (lighter fuels), the weight percentage of carbon decreases, while the proportion of hydrogen increases. Corresponding samples of exhaust gas from these successively lighter fuels will show decreasing percentages of carbon dioxide and increasing percentages of free hydrogen. Explanation of this increase in free hydrogen involves the water-gas reaction and analysis of chemical equilibrium in the combustion process (4) (5). The greater hydrogen content increases the thermal conductivity of the exhaust gas for any particular air-fuel ratio as compared with gasoline. It follows that the smaller the fuel molecule, the richer the reading would be for the given air-fuel ratio, since the smaller molecules have more hydrogen. For a measured air-fuel ratio of 14, the indicated air-fuel ratio for gasoline was 14; for iso-pentane, 12.6; for n-butane, 12.1; and for propane, 11.3, results which are in agreement with the above explanation. 6. Explanation of meter inaccuracy in the lean range. It was noticed that in the very lean ranges the air-fuel ratio instrument had a tendency to return to readings of lower air-fuel ratio. An examination of thermal conductivities of the exhaust gas constituents and typical exhaust-gas analyses explains why this occurs. The following table shows the thermal conductivities of exhaust gases as obtained from "Combustion," American Gas Association, 1939 (6). 'fable 4. THERMAL C0NDUcTIvITIEs OF VARIOUS ExHAusT GASES Gas Thermal conductivity Btu per F per in. per sec Carbondioxide --------------------------------------------------------------------------------------------Carbon monoxide ----------------------------------------------------------------------------------------- 0.000305 0.0000447 0.0000438 0.0000283 0.0000412 The thermal conductivities of oxygen, nitrogen, and carbon monoxide are about the same, but the thermal conductivity of hydrogen is approximately seven times that of oxygen, nitrogen, or carbon monoxide, and the conductivity of carbon dioxide is about 40 ver cent less than that of oxygen, nitrogen, and carbon monoxide. Ic AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES 17 The following table gives typical exhaust-gas analyses for gasoline at different air-fuel ratios Table 5. TYPICAL EXHAUST-GAS ANALYSES FOR SELECTED AIR-FUEL RATIOS A/F 13 14 15 16 17 18 19 H1 -------------------------------------------------------- 1.6 ------------------------------------------------------- 0.8 0.2 .... ... ------------------------------------------------------- . -------------------------------------------------------- . 02 0.9 0.7 1.0 1.9 3.0 3.9 4.8 N2 CO1 81.4 83.3 84.4 84.5 84.2 84.1 83.0 10.7 12.4 13.1 12.8 12.1 11.5 10.8 CO 4.8 2.3 1.1 0.6 [ 06 0.4 0.5 (Any residual percentage is methane.) It is evident that for rich mixtures the hydrogen content increases and the carbon dioxide decreases, thus increasing the thermal conductivity considerably. For lean mixtures the hydrogen content approaches zero, while the carbon dioxide remains high. Therefore the thermal conductivity is lowest at air-fuel ratios of 15-16. For very lean mixtures, excess air is introduced and the carbon dioxide content decreases. Oxygen, nitrogen, and a little carbon monoxide, in addition to the carbon dioxide, are all that remain in this very lean range. Since the conductivities of these remaining gases are the same, and the carbon-dioxide content is decreasing, the total conductivity will tend to become greater again. This, of course, causes the meter to swing back toward the lower air-fuel ratio values. curve. In Figure 6 this characteristic is plainly shown by the droop in each VI. CONCLUSIONS 1. Optimum air-fuel ratios for the hydrocarbcn fuels with which this investigation is concerned are: Air-fuel ratio Air-fuel ratio maximum power maximum economy Propane............................................................ 15.5 17.9 n-Butane .......................................................... 15.0 17.5 Iso-pentane ...................................................... 14.6 17.2 Iso-octane ........................................................ 13.7 16.6 Gasoline ............................................................ 13.0 16.0 Fuel 2. As the number of carbon atoms in the paraffinic hydrocarbon fuels becomes smaller, the air-fuel ratio for maximum power approaches the theoretical air-fuel ratio for perfect combustion. In the case of propane, which contains only three carbon atoms, maximum power occurred at an air-fuel ratio of 15.5, whereas the theoretical air-fuel ratio for perfect combustion is 15.7. 3. Air-fuel ratio for maximum economy in fuels having larger molecules is not greatly in excess of the theoretical air-fuel ratio for perfect combustion. The maximum economy air-fuel ratio for gasoline was found to be 16.0. The theoretical air-fuel ratio for perfect combustion is 15.0. 4. Maximum economy air-fuel ratio for the liquefied petroleum fuels is considerably higher than for gasoline, showing that leaner mixtures should be used with the very light fuels in order to obtain maximum economy conditions. 5. When the thermal-conductivity type air-fuel ratio meter is used for determining air-fuel ratios for the lighter fuels, indicated air-fuel ratios are lower than the true air-fuel ratio. The difference between the indicated and actual air-fuel ratio becomes greater as the molecule becomes smaller, due to the fact that the smaller molecules in a given hydroca:rbon series contain a lower percentage of carbon and a higher percentage of hydrogen. 6. The pointer of the thermal-conductivity type air-fuel ratio meter has a tendency to swing back toward lower air-fuel ratio readings when air-fuel ratios are very high. This is explained by the fact that there is an absence of hydrogen and a decreasing amount of carbon dioxide in the very lean range, resulting in a net increase in thermal conductivity. 18 VII. REFERENCES 1. SMITTENBERG, J. Octane ratings of a number of pure hydrocarbons and of some of their binary mixtures; CFR-ASTM Motor Method. Ji. Inst. of PetI, 26 :294-303, 1940. 2. VOGT, C. J. Some characteristics of internal-combustion engines when operating with butane-air mixtures. Oil and Gas JI., 34 :52-56, 1935. 3. GRAF, S. H., GLEaSON, G. W., and PAUL, W. H. Interpretation of exhaust gas analyses. Bull. 4, Engr. Expt. Station, Oregon State College, 1934. 4. GLEESON, G. W., and PAUL, W. H. Water gas reaction apparently controls engine exhaust gas composition. Nat. Pet. News, 28 :25-6, 1936. 5. GLEESON, G. W., and W000FIELD, F. W. Stoichiometric calculations of exhaust gas. Nat. Pet. News, 31 :R401-2, 1939. 6. AMERICAN GAS ASSOCIATION. Combustion, 3rd ed. Easton, Pa., Mack Printing Co., 1939. 7. DILWORTIT, J. L. Characteristics of exhaust gas analyzers. 48:234-239, 1941. 19 S.A.E. Jl., OREGON STATE COLLEGE ENGINEERING EXPERIMENT STATION CORVALLIS, OREGON LIST OF PUBLICATIONS BulletinsNo. 1. Preliminary Report on the Control of Stream Pollution in Oregon, by C. V. Langton and H. S. Rogers. 1929. None available. No. 2. A Sanitary Survey of the Willamette Valley, by H. S. Rogers, C. A. Mockmore, and C. B. Adams. 1930. Forty Cents. No. 3. The Properties of Cement.Sawdust Mortars, Plain, and with Various Admixtures, by S. H. Graf and R. H. Johnson. 1930. Twenty Cents. No. 4. Interpretation of Exhaust Gas Analyses, by S. H. Graf, G. W. Gleeson, and W. H. Paul. 1934. Twenty.five cents. No. 5. Boiler.Water Troubles and Treatments with Special Reference to Problems in Western Oregon, by R. E. Summers. 1935. Twenty.five Cents. No. 6. A Sanitary Survey of the Willamette River from Sellwood Bridge to the Columbia, by G. W. Gleeson. 1936. Twenty-five cents. No. 7. Industrial and Domestic Wastes of the Willamette Valley, by G. W. Gleeson and F. Merryfield. Fifty cents. No. 8. 1936. Ati Investigation of Some Oregon Sands with a Statistical Study of the Pre- dictive Values of Tests, by C. E. Thomas and S. H. Graf. 1937. Fifty Cents. No. 9. Preservative Treatments of Fence Posts. 1938 Progress Report on the Post Farm, by T. J. Starker, 1938. Twenty.five cents. No. 10. Precipitation-Static Radio Interference Phenomena Originating on Aircraft, by E. C. Starr, 1939. Seventy-five Cents. No. 11. Electric Fence Controllers with Special Reference to Equipment Developed for Measuring Their Characteristics, by F. A. Everest. Forty cents. No. 12. 1939. Mathematics of Alignment Chart Construction without the Use of Determinants, by J. R. Griffith. Twenty-five Cents. 1940. No. 13. Oil Tar Creosote for Wood Preservation, by Glenn Voorhies, 1940. Twenty-five Cents. No. 14. Optimum Power and Economy Air-Fuel Ratios for Liquefied Petroleum Gases, by W. H. Paul and M. N. Popovich. Twenty-five cents. No. 15. 1941. Rating and Care of Domestic Sawdust Burners, by E. C. Willey. Twenty-five Cents. 1941. CircularsNo. 1. A Discussion of the Properties and Economics of Fuels Used in Oregon, by C. E. Thomas and G. D. Keerins. 1929. Twenty-five cents. No. 2. Adjustment of Automotive Carburetors for Economy, by S. H. Graf and G. W. Gleeson. 1930. None available. No. 3. Elements of Refrigeration for Small Commercial Plants, by W. H. Martin. 1935. None available. No. 4. Some Engineering Aspects of Locker and Home Cold-Storage Plants, by W. H. No. 5. Martin. 1938. Twenty cents. Refrigeration Applications to Certain Oregon Industries, by W. H. Martin, 1940. Twenty-five cents. 20 AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES 21 Reprints No. 1. Methods of Live Line Insulator Testing and Results of Tests with Different Instruments, by F. 0. McMillan. Reprinted from 1927 Proc. N. W. Elec. Lt. and Power Assoc. Twenty Cents. No. 2. Some Anomalies of Siliceous Matter in Boiler Water Chemistry, by R. E. Summers. Reprinted from Jan. 1935, Combustion. Ten Cents. No. 3. Asphalt Emulsion Treatment Prevents Radio Interference, by F. 0. McMillan. Reprinted from Jan. 1935, Electrical West. None available. No. 4. Some Characteristics of A:C Conductor Corona, by F. 0. McMillan. from Mar. 1935, Electrical Engineering. None available. Reprinted No. S. A Radio Interference Measuring Instrument, by F. 0. McMillan and H. G. Reprinted from Aug. 1935, Electrical Engineering. Ten cents. Barnett. No. 6. Water.Gas Reaction Apparently Controls Engine Exhaust Gas Composition, by G. W. Gleeson and W. H. Paul. Reprinted from Feb. 1936, National Petro. leum News. Ten cents. No. 7. Steam Generation by Burning Wood, by R. E. Summers. Reprinted from April 1936, Heating and Ventilating. Ten cents. No. 8. The Piezo Electric Engine Indicator, by W. H. Paul and K. R. Eldredge. Reprinted from Nov. 1935, Oregon State Technical Record. Ten cents. No. 9. Humidity and Low Temperatures, by W. H. Martin and E. C. Willey. Reprinted from Feb. 1937, Power Plant Engineering. None available. No. 10. Heat Transfer Efficiency of Range Units, by W. J. Walsh. Aug. 1937, Electrical Engineering. None available. No. 11. Design of Concrete Mixtures, by I. F. Waterman. Concrete. Reprinted from Reprinted from Nov. 1937, None available. No. 12. Water.wise Refrigeration, by W. H. Martin and R. E. Summers. from July 1938, Power. None available. No. 13. Polarity Limits of the Sphere Gap, by F. 0. McMillan. 58, A.I.E.E. Transactions, Mar. 1939. Ten cents. Reprinted Reprinted from Vol. Influence of Utensils on Heat Transfer, by W. G. Short. Reprinted from Nov. 1938, Electrical Engineering. Ten cents. No. 15. Corrosion and Self-Protection of Metals, by R. E. Summers. Reprinted from Sept. and Oct. 1938, Industrial Power. Ten cents. No. 16. Monocoque Fuselage Circular Ring Analysis, by B. F. Ruffner. Reprinted from Jan. 1939, Journal of the Aeronautical Sciences. Ten Cents. No. 14. - No. 17. The Photoelastic Method as an Aid in Stress Analysis and Structural Design, by B. F. Ruffner. Reprinted from Apr. 1939, Aero Digest. Ten cents. No. 18. Fuel Value of Old.Growth vs. Second-Growth Douglas Fir, by Lee Gabie. Reprinted from June 1939, The Timberman. Ten cents. No. 19. Stoichiometric Calculations of Exhaust Gas, by G. W. Gleeson and F. W. Woodfield, Jr. Reprinted from November 1, 1939, National Petroleum News. Ten Cents. No. 20. The Application of Feedback to \Vide-Band Output Amplifiers, by F. A. Everest and H. R. Johnston. Reprinted from February 1940, Proc. of the Institute of Radio Engineers. Ten Cents. No. 21. Stresses Due to Secondary Bending, by B. F. Ruffner. Reprinted from Proc. of First Northwest Photoelasticity Conference, University of Washington, March 30, 1940. Ten cents. No. 22. Wall Heat Loss Back of Radiators, by E. C. Willey. Reprinted from November 1940, Heating and Ventilating. Ten cents. 22 ENGINEERING ExrERIIIENT STATION BULLETIN No. 14 Research Papers (Published as indicated. Not available from the Station.) No. 1. Electric Fish Screens, by F. 0. McMillan. Bulletin of the U. S. Bureau of Fisheries, vol. 44, 1928. Also in pamphlet form, U. S. Bureau of Fisheries, Document No. 1042. No. 2. Water Control of Dry Mixed Concrete, by G. W. Gleeson. Concrete Products, December 1929. No. 3. High.voltage Gaseous Conductor Lamps, by F. 0. McMillan and E. C. Starr. Trans. American Institute of Electrical Engineers, vol. 48, no. 1, pp. 11-18, 1929. No. 4. The Influence of Polarity in High.voltage Discharges, by F. 0. McMillan and E. C. Starr. Trans. American Institute of Electrical Engineers, vol. 50, no. 1, pp. 23-35, 1931. No. 5. Progress Report on Radio Interference from High.voltage Transmission Lines Pin and Pedestal Type Insulators, by F. 0. McMillan. Trans. 8th annual general meeting, Engineering Section, Northwest Electric Light and Power Assoc., 1931. No. 6. Aggregate Grading for Tamped Concrete Pipe, by G. W. Gleeson. Concrete, June 1932. Rock Products, 1932. Concrete Products, June 1932 and MayJune 1934. No. 7. Water Control of Dry Mixed Concrete, by G. \V. Gleeson. Concrete Products, September 1932, and Rock Products, November 1932. No. 8. Litharge and Glycerine Mortars, by G. W. Gleeson. October 13, 1932. No. 9. Radio Interference from Insulator Corona, by F. 0. Paper Trade Journal, Trans. American Institute of Electrical Engineers, vol. 51, no. 2, pp. 385-391, 1932. No. 10. The Coordination of High-voltage Transmission Lines with Radio, by F. 0. McMillan. Trans. 9th annual general meeting, Engineering Section, Northwest Electric Light and Power Assoc., 1932. McMillan. No. 11. Asphalt Emulsion Reduces Insulator Radio Troubles, by F. Electrical World, vol. 102, no. 6, August 5, 1933. No. 12. 0. McMillan. Silicon, a Major Constituent of Boiler Scales in Western Oregon, by R. E. Summers and C. S. Keevil. Paper presented at annual meeting, American Society of Mechanical Engineers, 1933. Abstracts published in Mechanical Engineering, vol. 55, p. 720, November 1933; Power, vol. 77, p. 687, midDec. 1933; and Power Plant Engineering, vol. 37, p. 519, December 1933, and vol. 38, p. 219, May 1934. No. 13. Study of the Frequency of Fuel Knock Noises, by P1. H. Paul and A. L. Albert. National Petroleum News, August 9, 1933. No. 14. The Pollutional Character of Flax Retting Wastes, by G. W. Gleeson, F. Merryfield, and E. F. Howard. Sewage \Vorks Journal, May 1934. No. 15. Siliceous Scales in Boilers of Western Oregon and Washington, by R. E. Summers and C. S. Keevil. The Timberman. vol. 35, p. 30, May 1934. No. 16. How Much Phosphate? by R. E. Summers. Power, vol. 78, p. 452, August 1934. No. 17. The Carbon Dioxide-Hydrogen Ratio in the Products of Combustion from Automotive Engines, by G. \V. Gleeson and W. H. Paul. National Petroleum News, September 15, 1934. Exhaust Gas Analysis, by G. W. Gleeson and W. H. Paul. Parts I, II, and III. National Petroleum News, September 26, October 3 and 10, 1934. No. 19. Simplified Measurements of Sound Absorption, by A. L. Albert and T. B. No. 18. Wagner. Electrical Engineering, vol. 53, no. 8, P. 1160, August 1934. No. 20. Treatment and Recovery of Sulfite Waste, by F. Merryfield. Civil Engineering, June 1936. No. 21. Industrial Wastes in the Willamette Valley, by F. Merryfield. Civil Engineer. ing, October 1936. No. 22. Flow Characteristics in Elbow Draft-Tubes, by C. A. Mockmore. Proc. American Society of Civil Engineers, vol. 63, no. 2, pp. 251-286, Feb. 1937. No. 23. Some Simple Experiments Dealing with Rates of Solution, by G. W. Gleeson. Journal of Chemical Education, vol. 15, no. 4, April 1938. No. 24. Heat Transfer Coefficient in Boiling Refrigerant, by W. H. Martin. Refrigerating Engineering, vol. 36, no. 3, September 1938. No. 25. Kiln Drying Guaranteed Moisture Content Spruce Lumber, by Glenn Voorlmies. West Coast Lumberman, vol. 66, no. 1. January 1939. No. 26. Steam Demand in Drying Douglas Fir Lumber, by Glenn Voorhies. The Timberman, vol. 40, no- 4, February 1939. No. 27. Aircraft Precipitation-Static Radio Interference, by E. C. Starr. American Institute of Electrical Engineers, Preprint, May 1940. AIR-FUEL RATIOS FOR LIQUEFIED PETROLEUM GASES No. 28. High-Voltage D.0 Point Discharges, by E. C. Starr. Electrical Engineers, Preprint, May 1940. 23 American Institute of No. 29. Humidity in the Freezing Chamber, by W. H. Martin. Western Frozen Foods, voi. 1, no. 7, May 1940. 2Jan'42 THE ENGINEERING EXPERIMENT STATION STAFF R. H. DEARBORN, Dean and Director of Engineering. S. H. GRAF, Director of Engineering Research. A. L. ALBERT, Commimication Engineering. F. A. EVEREST, Radio Engineering. G. W. GLEESON, Chemical Engineering. BURDETTE GLENN, Highway Engineering. J. R. GRIFFITH, Structural Engineering. F. 0. McMILLAN, Electrical Engineering. W. H. MARTIN, Mechanical Engineering. E. G. MASON, Forestry. FRED MERKYFIELD, Sanitary Engineering. C. A. MOCKMORE, Civil and Hydraulic Engineering. W. H. PAUL, Automotive Engineering. B. F. RUFFNER, Aeronautical Engineering. E. C. STARR, Electrical Engineering. C. E. THOMAS, Engineering Materials. GLENN VooRHIEs, Wood Products. Technical Counselors R. H. BALDOCK, State Highway Engineer, Salem. R. R. CLARK, Designing Engineer, Corps of Engineers, Portland District, Portland. R. G. DIECK, Consulting Civil Engineer, Portland. C. V. LANGTON, Professor of Hygiene, Oregon State College. C. B. MCCULLOUGH, Assistant State Highway Engineer, Salem. PAUL B. MCKEE, President, Portland Gas and Coke Company, Portland. J. H. POLHEMUS, President, Portland General Electric Company. J. C. STEVENS, Consulting Civil and Hydraulic Engineer, Portland. C. E. STRICKLIN, State Engineer, Salem. Oregon State College Corvallis RESIDENT INSTRUCTION Liberal Arts and Sciences THE LOWER DIVISION (Junior Certificate) SCHOOL OF SCIENCE (B.A., B.S., MA., MS., Ph.D. degrees) The Professional and Technical Schools SCHOOL OF AGRICULTURE (B.S., B.Agr., M.S., Ph.D. degrees) SCHOOL OF EDUCATION (B.A., B.S., BEd., M.A., M.S., Ed.M., Ed.D. degrees) SCHOOL OF ENGINEERING AND INDUSTRIAL ARTS (B.A., B.S., M.A., M.S., OLE., C.E., E.E., M.E. degrees) SCHOOL OF FORESTRY (B.S., B.F., M.S., M.F., F.E. degrees) SCHOOL OF HOME ECONOMICS (B.A., B.S., M.A., M.S. degrees) SCHOOL OF PHARMACY (B.A., B.S., M.A., M.S. degrees) DEPARTMENT OF SECRETARIAL SCIENCE (B.A., B.S., B.S.S. degrees) The Graduate Division (M.A., M.S., ELM., M.F., Ch.E., C.E., E.E., F.E., M.E., Ed.D., Ph.D. degrees) The Summer Sessions The Short Courses RESEARCH AND EXPERIMENTATION The General Research Council The Agricultural Experiment St.tion The Central Station, Corvallis The Union, Moro, Hermiston, Talent, Burns, Astoria, Hood River, Pendleton, Medford, and Squaw Butte Branch Stations The Engineering Experiment Station, Corvallis EXTENSION Federal Cooperative Extension (Agriculture and Home Economics) General Extension Division