Wood Use in Colorado at the Turn of the

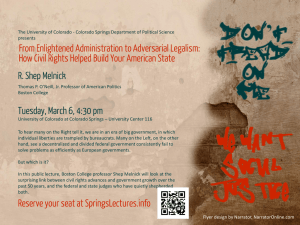

advertisement