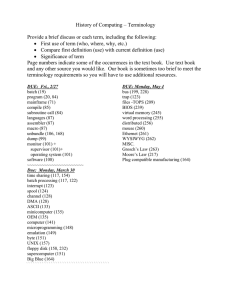

Order Picking: Pick Sequencing and Batching

advertisement

Order Picking:

Pick Sequencing and Batching

The Pick Sequencing Problem

Given a picking list, sequence the visits to the picking

locations so that the overall traveling effort (time) is

minimized.

x

x

x

x

x

x

x

x

x

Docking station

x

Problem Abstraction:

The Traveling Salesman Problem (TSP)

Given a complete TSP graph:

2

c_ij

3

1

5

4

find a tour that visits all cities, with minimal total (traveling) cost;

2

e.g.:

3

1

5

4

<1, 2, 5, 3, 4>

Analytical Problem Formulation

Parameters:

– N : graph size (number of graph nodes)

– c_ij : cost associated with arc (i,j)

Decision Variables:

– x_ij : binary variable indicating whether arc (i,j) is in the optimal

tour

– u_i : auxiliary (real) variable for the formulation of the “no

subtour” constraints

min _i _j c_ij x_ij

s.t.

_j x_ij = 1 i

_i x_ij = 1 j

(No subtours:

u_i - u_j + N x_ij N-1 i,j {2,…,N} and ij )

x_ij {0, 1} i,j

Some remarks on the TSP problem and

its application in pick sequencing

• The TSP problem is an NP-complete problem: It can be solved

optimally for small instances, but in general, it will be solved through

heuristics.

• There is a vast literature on TSP and the development of heuristic

algorithms for it (e.g., Lawler, Lenstra, Rinnooy Kan and Shmoys,

“The Traveling Salesman Problem: A guided tour of combinatorial

optimization”, John Wiley and Sons, 1985).

• When the “no subtour” constraint is removed, the remaining

formulation defines a Linear Assignment Problem (LAP) (which is an

easy one; e.g., the “Hungarian Algorithm”) => Solving the

corresponding LAP can provide lower bounds for assessing the suboptimality of the solutions provided by the applied heuristics.

• In the considered application context, the distances c_ij should be

computed based on the appropriate distance metric; i.e., rectilinear,

Tchebychev, “shortest path”

The closest insertion algorithm:

A TSP heuristic (symmetric version)

Initialization:

S_p = <1>; S_a = {2,…,N}; c(j) = 1, j {2,…,N}; n=1;

While n < N do

n = n+1;

Selection step:

j* = argmin_{j S_a}

S_a = S_a \ {j*};

Insertion step:

{c_{j,c(j)}};

i* = argmin_{i =1}^|S_p| {c_{[i],j*} + c_{j*,[i mod |S_p|+1]}

- c_{[i],[i mod |S_p|+1]}};

S_p = < [1],…,[i*], j*, [i*+1],…,[n]>;

j S_a, if c_{j,j*} < c_{j,c(j)} then c(j) = j*;

Remarks: 1. [i] denotes the node at i-th position of the constructed sub-tour.

2. If the distances are symmetric and satisfy the triangular inequality, the cost of

the solution provided by this heuristic is no worse than twice the optimal cost.

k-STRIP: A computationally simple

heuristic for rectangular areas

x

x

x

x

x

x

x

x

x

x

x

x

I/O point

• When A is the unit square, an optimized k = (n/2) , and for this value, the worstcase tour length generated by the heuristic is between 1.075n and 1.414 n, for large n.

• The computational complexity is O(n logn).

• Supowit, Reingold and Plaisted, “The traveling salesman problem and minimum

matching in the unit square”, SIAM J. Computing, 12(1): 144-156, 1983.

The bin-numbering heuristic

(Bartholdi and Platzman, Material Flow, 4: 247-254, 1988)

• Basic idea: Number bins / storage locations in a way that

filling the orders by visiting the associated bins in

increasing numbers will lead to efficient routings.

• Advantages:

– Once the numbering is established, developing the order routes

becomes extremely simple.

– Easy to adjust routes dynamically upon the arrival of new orders.

• Basic underlying problem:

How do you establish good bin-numbering schemes?

Example of a numbering scheme

(Is it a good one?)

25

27

28

26

30

2

2

42

29

15 4 58

14

13

1

1

43

2

5

64

47

4

8

48

44

31

32

33

3

19

11

20

21

41

12

18

45

4 46

7

9

6

16

50

52

51

36

57

35

7

37

53

7

49

56

60

38

34

59

54

61

55

11

22

6

24

17

23

10

62

39

63

40

Order: {1, 10, 13, 28, 30, 44, 50, 62}

Resulting route length: 44 (using rectilinear distances of the cell

centroids)

An alternative numbering scheme

16

13

15

2

12

9

8

4

5

17

18

20

4 19

11

21

22

44

10

24

23

41

42

7

25

26

40

39

57

58

6

28

27

37

38

60

59

14

2

48

45

4

3

29

30

36

1 1

2

32

31

33

1

7

Order: {1,4,12,14,21,48,58,64}

Resulting route length: 32

47

46

49

50

52

51

43 7 53

54

35

34

56

61

64

55

4

62

63

Key concept: Space-filling curves

(see also http://www.isye.gatech.edu/faculty/John_Bartholdi/mow/mow.html)

• Closed curves that sweep the entire region while preserving nearness.

• Technically, they define a continuous mapping of the unit interval on the unit

square.

• Typical example: Sierpinski’s space-filling curve:

The Sierpinski space-filling curve

Applying the Sierpinski space-filling curve

in the previous bin-numbering example

20

21

23

19

18

22

17

2

14

6

5

2

1

1

1

6

13

32

33

35

36

25

31

30

34

37

28

297

38

39

27

42

41

40

15

12

26

11

7

9

10

43

44

45

46

4

8

61

60

59

48

47

2

16

4

24

3

62

57

58

53

64

63

56

55

54

7

Order: {1,2,13,17,18,32,46,52}

Resulting route length: 34

49

52

4

50

51

Some properties of the bin-numbering

schemes based on the Sierpinski

space-filling curve

• If n locations are to be visited throughout a warehouse of

area A, then the length of the retrieval route is at most

(2nA).

• If every location is equally likely to be visited, then on

average, the retrieval route produced by the corresponding

bin-numbering heuristic will be 25% longer than the

shortest possible route length.

• The above results have been derived using the Euclidean

metric for measuring the traveling distances, but they are

robust with respect to other metrics that preserve

“closeness” according to the Euclidean metric.

Characterizing the best bin-numbering

scheme...

• …is computationally very hard.

• Some good schemes can be obtained through interchange

techniques (e.g., 2 or 3-opt), where the efficiency of each of

the considered schemes is evaluated through simulation.

• The optimal bin-numbering scheme depends on:

– the underlying geometry of the picking facility

– the frequency with which the various storage locations are visited

(and therefore, the applying storage policy)

• In general, the logic underlying the utilization of the spacefilling curves is more useful / pertinent for storage areas with

small visitation frequencies for their locations.

• For areas with high visitation frequencies, numbering

schemes suggesting an exhaustive sweeping of the region

tend to perform better (c.f., Bartholdi & Platzman, pg. 252).

Bin-numbering in structures with

complicated geometry

When the considered area has a structure too complex to

measure traveling effort by Euclidean or a relative metric,

the logic underlying the application of space-filling curves

to bin-numbering can be applied in a hierarchical fashion:

• separate the entire area under consideration to smaller

areas of simpler geometry;

• design a numbering sequence for each of these areas using

the space-filling curve logic;

• develop a visiting sequence for the areas developed in step

1, by passing a space-filling curve among their I/O points.

Order Batching

(based on De Koster et. al., “Efficient

orderbatching methods in warehouses”, Inlt.

Jrnl of Prod. Res., Vol. 37, No. 7, pgs 14791504, 1999)

Problem Description

• Given a set of orders, cluster them into batches - i.e.,

subsets of orders that are to be picked simultaneously by

one picker at a single trip – such that

– the total traveling distance / time is minimized

– while each batch does not exceed some measure of the

picker capacity (e.g., number of items / volume of the

resulting batch, number of distinct orders in a batch)

• Theoretically, the problem can be solved by:

– enumerating all feasible partitions of the given order set into

batches;

– evaluating the total traveling distance / time for each partition;

– picking the partition with the smallest traveling distance / time.

• However, combinatorial explosion of partitions =>

heuristics

Order-Batching Heuristics

Naive

FCFS

Intelligent

Seed Algorithms

(Orders are clustered (Batches are built

based on the sequence sequentially, one at

a time)

of their appearance)

Savings Algorithms

(All batches are built

simultaneously, by

merging partially

developed batches)

The generic structure for seed algorithms

• While there are unprocessed orders,

– Pick a new seed order according to some seed selection

rule;

– while there are unprocessed orders and the batch has

not reached the imposed capacity limit

• pick a new order to be added to the batch according

to an order addition rule;

• add the selected order to the batch, provided that the

imposed capacity limit is not violated;

• (update the batch seed to the union of the previous

batch seed and the new order)

Typical seed selection rules

•

•

•

•

Random selection

the order with the farthest item (w.r.t. the shipping station)

the order with the largest number of aisles to be visited

the order with the largest aisle range (absolute difference

between the most left aisle number and the most right aisle

number to be visited)

• the order with the largest number of items

• the order with the longest travel time

• Remark: If the batch seed is updated after every order

addition, the algorithm is characterized as dynamic or

cumulative mode; ow., it is said to be static or single mode.

Typical order addition rules

• Time saving: choose the order that, together with the batch

seed, ensures the largest time saving compared with the

individual picking of the two orders.

• Choose the order that minimizes the number of additional

aisles, compared to the seed order, that have to be visited

by the resulting batch route.

• Choose the order for which the absolute difference

between the order’s center of gravity (COG) and the COG

of the batch seed is the smallest; COG is the weighted

average aisle number of the order, with the aisle weights

defined by the number of items in the aisle.

• Choose the order with the property that the sum of

distances* between every item of the seed and the closest

item in the order is minimized.

• * distances must be measured by an appropriately selected

metric

The (standard) savings algorithm

• Initialization: B: = order set (each order defines its own

batch)

• Repeat

– For each pair (i,j) in the current batch set B

• compute the time savings s_ij = t_i + t_j - t_ij,

where t_i (resp., t_j) is the time required for picking

batch I (resp., j) and t_ij is the time required for

picking the batch resulting from the merging of

batches i and j.

– Rank batch pairs (i,j) in decreasing s_ij.

– Pick the first batch pair (i,j) in the ranked list, for which

the merging of its constituent batches does not violate

the imposed capacity limit, and merge batches i and j: B

:= (B-{i,j}) U {i+j}

until no further batch merging is possible.

• Remark: The algorithm result depends on the adopted pick

sequencing rule.

Some findings regarding the (relative)

performance of the presented batch

algorithms (De Koster et. al.)

• Intelligent batching leads to significant improvements compared to

single-order picking and naïve batching schemes.

• In seed algorithms, dynamic seed definition leads to better

performance than static seed definition.

• The best seed selection rules are focusing on orders dispersed over a

large number of aisles and involving long travel times.

• The best order addition rules (c.f. corresponding slide) tend also to be

the most robust (i.e., they yield the best results in all warehouse

configurations considered in the simulation).

• Savings algorithms have good performance, in general, but they tend

to be computationally more expensive than seed algorithms.

• The performance of the applied batching algorithm has a significant

dependence on the adopted pick sequencing rule.

• The largest the number of orders per batch (the batch capacity limit),

the smaller the savings from intelligent batching (and therefore,

simpler batching schemes become more eligible candidates)

Addendum:

A special case admitting

polynomial solution

(Ratliff and Rosenthal, Operations Research,

31(3): 507-521, 1983)

The considered warehouse layout

Crossover Aisles

x

x

x

x

x

x

x

x

x

x

Items

to be

picked

x

x

Picking Aisles

Docking station

A graph-based representation of the

underlying topology

a2

a3

2

a4

2

a5

2

a6

2

2

3

4

v3

3

v2

v5

v4

3

v7

v11

15

v9

x

7

6

x

7

v1

5

v6

3

b1

8

6

x

3

2

b2

v12

x

3

x

x

5

x

v8

x

2

x

v10

x

x

4

3

x

a1

b3

0

2

b4

v0

2

2

b5

2

b6

A picking tour

a2

a3

2

a4

2

a5

2

a6

2

2

3

4

v3

3

v2

v5

v4

3

v7

v11

15

v9

x

7

6

x

7

v1

5

v6

3

b1

8

6

x

b2

2

x

v10

v0

3

2

v12

x

3

x

x

5

x

v8

x

x

x

4

3

x

a1

b3

2

b4

2

2

b5

2

b6

Lj-, Aj and Lj+ sub-graphs, j=1,2,…,n

a2

a3

2

a4

2

a5

2

a6

2

2

3

4

v3

3

v2

v5

v4

3

v7

v11

15

v9

x

7

6

x

7

v1

5

v6

3

b1

8

6

x

b2

2

x

v10

v0

3

2

v12

x

3

x

x

5

x

v8

x

x

x

4

3

x

a1

b3

2

b4

Lj+ = Lj- Aj

2

2

b5

2

b6

Lj(- or +) PTS (partial tour sub-graph)

a2

a3

2

a4

2

a5

2

a6

2

2

3

4

v3

3

v2

v5

v4

3

v7

v11

15

v9

x

7

6

x

7

v1

5

v6

3

b1

8

6

x

b2

2

x

v10

v0

3

2

v12

x

3

x

x

5

x

v8

x

x

x

4

3

x

a1

b3

2

b4

L3- PTS : (E, E, 2C)

L3+PTS: (U, U, 1C)

2

2

b5

2

b6

A key observation

The only possible characterizations for an Lj (- or +) PTS are the

following:

• (U, U, 1C)

• (0, E, 1C)

• (E, 0, 1C)

• (E, E, 1C)

• (E, E, 2C)

• (0, 0, 0C)

• (0, 0, 1C)

where the triplet (X, Y, Z) should be interpreted as follows:

• X (Y): degree parity for node a_j (b_j) - 0, Even, Uneven (odd)

• Z: number of connected components in Lj PTS, excluding the

vertices with zero degree

Going from Lj- to Lj+…

a_j

b_j

(I-i)

a_j

a_j

a_j

a_j

b_j

b_j

b_j

b_j

(I-ii)

(I-iii)

(I-iv)

(I-v)

a_j

b_j

(I-vi)

Going from Lj- to Lj+…(cont.)

TABLE I

Lj- class

(U,U,1C)

(E,0,1C)

(0,E,1C)

(E,E,1C)

(E,E,2C)

(0,0,0C)b

(0,0,1C)c

(I-i)

(E,E,1C)

(U,U,1C)

(U,U,1C)

(U,U,1C)

(U,U,1C)

(U,U,1C)

d

(I-ii)

(U,U,1C)

(E,0,1C)

(E,E,2C)

(E,E,1C)

(E,E,2C)

(E,0,1C)

(I-iii)

(U,U,1C)

(E,E,2C)

(0,E,1C)

(E,E,1C)

(E,E,2C)

(0,E,1C)

(I-iv)

(U,U,1C)

(E,E,2C)

(E,E,2C)

(E,E,1C)

(E,E,2C)

(E,E,2C)

(I-v)

(U,U,1C)

(E,E,1C)

(E,E,1C)

(E,E,1C)

(E,E,1C)

(E,E,1C)

(I-vi)a

(U,U,1C)

(E,0,1C)

(0,E,1C)

(E,E,1C)

(E,E,2C)

(0,0,0C)

(0,0,1C)

a: This is not a feasible configuration if there is any item to be picked in aisle j

b: This class can occur only if there are no items to be picked to the left of aisle j

c: This class is feasible only if there are no items to be picked to the right of aisle j

d: Could never be optimal

Going from Lj+ to L(j+1)-…

a_j

a_j

a_j+1

b_j

b_j+1

a_j+1

b_j

(II-i)

a_j

b_j+1

b_j

a_j+1

b_j

b_j+1

(II-iv)

b_j+1

(II-iii)

(II-ii)

a_j

a_j+1

a_j

a_j+1

b_j

b_j+1

(II-v)

Going from Lj+ to L(j+1)-…(cont.)

TABLE II

Lj+ class

(II-i)

(U,U,1C) (U,U,1C)

(E,0,1C)

a

(0,E,1C)

a

(E,E,1C)

a

(E,E,2C)

a

(0,0,0C)

c

(0,0,1C)

b

(II-ii)

a

(E,0,1C)

b

(E,0,1C)

b

c

b

(II-iii)

a

b

(0,E,1C)

(0,E,1C)

b

c

b

a: The degrees of a_j and b_j are odd.

b: No completion can connect the graph.

c: Would never be optimal.

(II-iv)

a

(E,E,2C)

(E,E,2C)

(E,E,1C)

(E,E,2C)

c

b

(II-v)

a

(0,0,1C)

(0,0,1C)

(0,0,1C)

b

(0,0,0C)

(0,0,1C)

A polynomial-complexity algorithm for

computing a minimum-length tour

• Initialization: L1- PTS = null graph for every class type

• For <L1+, L2-, L2+,…,Ln-, Ln+)

– compute a minimum-length PTS for each of the seven

classes, using the minimum-length PTS’s constructed in

the previous stage, and the information provided in

Tables I and II.

– Remark: For case (I-iv), a minimum-length PTS is

obtained by putting the gap between the two adjacent

v_i’s in aisle j that are farthest apart.

• A minimum-length tour is defined by a minimumlength Ln+ PTS.

Example (c.f., slide 8)

PTS-class

1.(U,U,1C)

2.(E,0,1C)

3.(0,E,1C)

4.(E,E,1C)

5.(E,E,2C)

6.(0,0,0C)

7.(0,0,1C)

L1-

PTS-class

1.(U,U,1C)

2.(E,0,1C)

3.(0,E,1C)

4.(E,E,1C)

5.(E,E,2C)

6.(0,0,0C)

7.(0,0,1C)

L457,1,II-I

60,4,II-ii

60,4,II-iii

64,4,II-iv

64,5,II-iv

L1+

15,-,I-I

24,-,I-ii

22,-,I-iii

30,-,I-v

20,-,I-iv

L219,1,II-I

28,2,II-ii

26,3,II-iii

38,4,II-iv

28,5,II-iv

L2+

37,1,I-iv

48,2,I-ii

48,3,I-iii

34,1,I-I

44,3,I-?

22,3,II-v

56,4,II-v

L4+

57,1,I-iii

90,2,I-ii

60,3,I-iii

64,4,I-iii

60,2,I-iii

L561,1,II-I

68,4,II-ii

64,3,II-iii

72,4,II-iv

68,3,II-iv

60,3,II-v

L341,1,II-I

38,4,II-ii

38,4,II-iii

42,4,II-iv

52,5,II-iv

L3+

53,2,I-I

62,2,I-ii

62,3,I-iii

56,1,I-I

56,2,I-iv

34,4,II-v

L5+

75,1,I-iii

84,2,I-ii

78,2,I-iii

76,1,I-I

80,3,I-ii

L679,1,II-I

80,4,II-ii

80,4,II-iii

84,4,II-iv

86,3,II-iv

76,4,II-v

L6+

95,1,I-iv

106,2,I-ii

104,3,I-iii

94,1,I,I

96,2,I,iv

Example: The optimal tour

a2

a3

2

a4

2

a5

2

a6

2

2

3

4

v3

3

v2

v5

v4

3

v7

v11

15

v9

x

7

6

x

7

v1

5

v6

3

b1

8

6

x

3

2

b2

v12

x

3

x

x

5

x

v8

x

2

x

v10

x

x

4

3

x

a1

b3

0

2

b4

v0

2

2

b5

2

b6