Iowa Farmer Today 04-22-06 Hoops hold promise for cattle feedlots

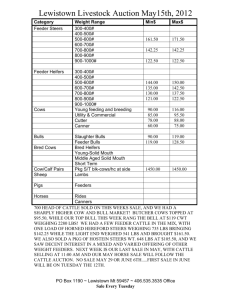

advertisement

Iowa Farmer Today 04-22-06 Hoops hold promise for cattle feedlots By Jeff DeYoung, Iowa Farmer Today LEWIS -- From a distance, it might resemble an oversized greenhouse but Iowa State University researchers are proving cattle can grow just as well in hoop buildings as they can in a semi-confinement feedlot. “The performance we have seen in the hoop building is statistically equal to what we have seen in semi-confinement,” says Shawn Shouse, ISU Extension ag engineer near here in Pottawattamie County. “It’s really done what we expected it to do.” The structure was erected in 2004 at the Armstrong Research and Demonstration Farm here, with the first set of cattle placed late in the year. The hoop building is 50-feet wide by 120-feet long, with pre-cast concrete feed bunks outside of the building posts and along a side wall. The building has a capacity of 120 head, with three pens of 40 cattle each. Total square footage allowed for 50 sq. ft. per head in the building, with one linear foot of bunk space per animal. The structure was built to face the north and the south. A 10-inch wide ridge vent helps with temperature control during the summer. The west wall is lined with lumber to further reduce summer heat. The initial group in the hoop building had 72 steers and 34 heifers. Steers weighed an average of 652 pounds, while heifers weighed an average of 611 lbs. The steers spent 138 days on feed, with a final weight of 1,166 lbs. and an average daily gain (ADG) of 3.74 lbs. Heifers spent 133 days on feed, weighing an average of 1,064 lbs. with an ADG of 3.43 lbs. About 75 percent of the initial group was black-hided. Eighty-nine percent of the steers and 100 percent of the heifers graded low Choice or better. The control group in the semi-confinement nearby spent 141 and 137 days on feed for steers and heifers, respectively, with nearly identical ADG compared to the cattle in the hoop building. Seventy-one percent of those cattle were blackhided, with 79 percent of the steers and 87 percent of the heifers grading low Choice or better. “We have some data from a couple of semi-confined feedlots in the area that have seen a three to five percent improvement in gain over outside lots,” says Darrell Busby, ISU Extension beef specialist. “Some of that is going to depend on the weather but it looks like performance is going to be better when there is some confinement.” Shouse says similar rations were used with both groups, comprising whole corn and ground hay, with some ground cornstalks and supplements. He says with the smaller calves, feeding areas were cleaned weekly. The rest of the pen was cleaned out between groups. Cornstalk bedding was added every two weeks for calves. The second and third groups of cattle have been yearlings, Shouse says. With the large cattle, feeding areas are cleaned every five days and bedding is added weekly. Cattle are kept outside during the cleaning process. Shouse adds cornstalk bales are kept for windbreaks to the north of the hoop structure. “We haven’t had a real bad winter lately but there have been occasions where some snow gets into the building,” he says. “But, the cattle don’t seem to mind and they haven’t gotten cold enough where their performance would be affected.” The hoop building has also held up well structurally, Shouse says. The building also provides producers with an effective manure-management tool, he says. “We are seeing an increase in enforcement of the Clean Water Act, and open feedlot runoff is becoming much more of an issue,” Shouse says. “With the bedded confinement building, you do not have to build costly deep pits.” Used bedding and manure are composted for use with organic plots at another research farm. Shouse says the bedding could safely be applied to a field and incorporated much like manure but would have to be stored in a building or have protective storage until it is applied. Shouse adds the hoop building cost about $44,000, approximately $370 per head of capacity. Busby says producers who have feedlots near a creek or other waterway could use a hoop structure to reduce the risk of manure entering the water. “If you think of some of these older feedlots building near a creek because of the water source, I think you could retrofit a hoop over the lot and help you comply with regulations,” he says. Busby adds early data from the hoop building and semi-confinement feedlot reinforce the importance of animal comfort when it comes to performance. “If they aren’t comfortable, they aren’t going to perform in any kind of lot.”