NAVAL POSTGRADUATE SCHOOL

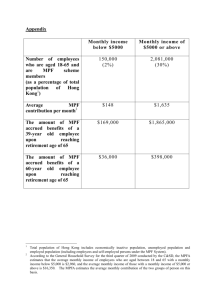

advertisement