ECONOMICS OF PACKAGED LUMBER John R. Host Associate Market Analyst

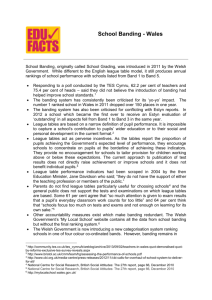

advertisement

ECONOMICS OF PACKAGED LUMBER John R. Host Associate Market Analyst U. S. Forest Service Intermountain Forest and Range Experiment Station Missoula, Montana As kiln operatores, you are primarily concerned with producing correctly dried lumber that will run through the planer with a minimum of difficulty and produce a good surface. You should also be concerned with the condition of that lumber when it reaches the final consumer. Properly dried and surfaced lumber is a perishable product in that it all too easily can change or deteriorate in the time between leaving the planer and the time it is delivered to the consumer. Packaging is one method of reducing this perishability. The purpose of this paper is to present some cost-benefit relations derived from banding and wrapping lumber. The cost data were determined from figures given by sic representative mills in western Montana. I will also give some conclusions based on this study. Banding and Wrapping Process. The banding and wrapping process is known to all of you. But, because it can be done in many ways, I briefly explain my version of it so we will all be on common ground. Banding lumber by machine is a simple process. Standard loads are compressed while the banding is applied and sealed under tension. This combination of compression and tension is a primary factor in preventing coring; this is a big advantage of machine banding over hand banding. The term "machine wrapping" is a misnomer. It is used because the method described here is used in conjunction with a semiautomatic banding machine operation. The wrapping material is pulled downward from a roll onto the banded unit and it is stapled along the bottom with a pneumatic stapler. When banding and wrapping are done by hand, the loads are placed on the ground and banding is applied with a manual tensioner and sealer. The packages are then wrapped by placing a piece of wrapping material over'the package and stapling it to the lumber along the bottom of the package. Production Costs. Before presenting actual cost figures it is necessary again to establish a common ground from which we can all proceed. -6- Table 1. Basic Assumptions. 1. Regular unit package is 2' x 4' x 16' and contains 1, 920 board feet. 2. Gross wage rate is $3. 40 per hour. - 3. A forklift machine costs $0. 834 per hour to operate. 4. 5. Semiautomatic banding machine is amortized at $2, 500 per year. Production rate for machine banding and wrapping is 12 units or 23,040 board feet per hour. 6. Carload volume is 40 M board feet. First, for the sake of simplification, six assumptions are made: 1. 2. The regular unit package is 2° high, 4' wide, and 16' long. It contains 1, 920 board feet. Gross wage rate is $3. 40 per hour. This consists of $2. 70 direct and $0. 70 overhead, but does not include supervision. 3. A forklift machine costs $0. 834 per hour to operate. 4. The semiautomatic banding machine costs $12, 500 installed and is amortized at $2, 500 per year for 5 years. This includes the cost of the wrapping facility. 5. Production rate for machine banding and wrapping is 12 units or 23,040 board feet per hour. 6. Carload computations are based on a car volume of 40 M board feet. These assumptions are necessary in order to keep this talk down to a reasonable length and so we can proceed without referring back to them regularly. On the basis of the six previous assumptions the cost per M board feet for mechanical banding is: Table 2. Machine Banding Costs Per M Board Feet Cost (Dollars) Item $0. 295 Labor Machine amortization . 256 Materials . 157 Forklife operation . 037 $0. 745 Total Labor costs $0.295 per M board feet. Two men are used: a forklift operator, to deliver loads to the infeed conveyor and remove banded packages from the outfeed conveyor; and banding machine operator. Producing 23 M board feet at $6, 80 per hour, the cost is $0. 295 per M board feet. Banding machine amortization is $0. 256 per M board feet. The median annual production of the operations sampled is 9. 25 MM board feet. Using this volume to amortize $2, 500 the charge is $0. 26 per M board feet. Banding materials cost $0. 157 per M board feet. Currently available price lists for materials show that banding and seals cost $0. 157 per M board feet Forklift operation costs $0. 037 per M board feet, At 23 M board feet production per hour, the cost is $0.037 per M. -7- Mechanical Wrapping. Mechanical wrapping requires two men. Their production rate is the same as for banding, so the labor cost for wrapping is the same as for banding-- $0. 295 per M board feet. Table 3. Mechanical Wrapping Costs per M Board Feet Cost (Dollars) Item $0.295 Labor . 975 Materials $1.270 Total Wrapping materials cost $0.975 per M board feet. The per M cost of wrapping materials is a function of unit length for a given package height and width. Materials for a package length of 16 feet amount to $1. 87 for wrapping and staples. The 16-foot package of 1,920 board feet then costs $0. 975 per M for materials. The total cost for machine banding and wrapping is $2.015/M B. F. Hand Banding. Table 4. Hand Banding and Wrapping . Costs per M Board Feet Cost (Dollars) Item Banding $0. 765 Labor Materials 157 Forklift 020 $0.942 Subtotal Wrapping $0. 680 Labor . 975 Materials $1.655 Subtotal $2. 597 TOTAL Banding a package of lumber by hand requires two men for applying the banding and a part-time forklift operator, This crew can band 10 M board feet per hour. The labor cost is.$0.765 per M board feet. The cost of banding materials is $0. 157 per M board feet. To operate the forklift machine costs $0.02 per M board feet. Hand Wrapping. Labor for hand wrapping costs $0.68 per M and materials cost $0. 975 per M. Total cost for banding and wrapping by hand is $1.655 per M board feet. Cost Comparisons. These tables quickly summarize the costs determined for banding and wrapping. They show a distinct cost advantage for the mechanical method. ilowever, a break-even analysis will show a different picture. Remember, one of our assumptions was that we had a fixed annual amortization charge of $2, 500. We also derived a per M machine cost based on 9.25 MM board feet annual production. Assuming all other conditions remaining constant and varying annual production volume, the cost situation varies. (Table 5) -8- This chart shows that the break-even point for banding is at 5. 5 MM per year. The lower curve intersects the lower horizontal line at 5. 5 MM annual production. This shows that if you intend only to band lumber packages and expect the annual volume to be less than 5. 5 MM, you are better off not to use a banding machine. Looking at the upper curve and where it intersects the upper horizontal line you will notice that the breakeven point has shifted to the left. This means that if you contemplate wrapping all the material that is banded, the break-even production volume is reduced to about 3.0 MM per year. Loading and Unloading Lumber. This part of the study compares the cost of loading and unloading railcars with packaged vs, loose (unpackaged) lumber. Loading Flatcars, Table 6. Railcar Loading Costs per M Board Feet Cost (Dollars) Item Flatcar $0. 34 Lab or Materials . 25 Dunnage . 44 Forklift 04 Total $1.07 Total $2. 15 Boxcar Loading flatcars with packaged lumber follows rules prescribed by the American Association of Railroads. A forklift with operator and one additional man are needed to load and strap the packages onto the car. This labor costs $0. 34 per M board feet. Banding materials cost $0.25 per M board feet. The dunnage is another $0. 44 per M board feet. The forklift costs $0. 04 per M board feet. This provides a total loading cost of $1.07 per M. Loading Boxcars. Because of the variations in organizing personnel, it is difficult to determine a representative cost for loading boxcars. An average cost of $2. 15 per M is used. Gyppo loaders can do it for less, but hourly rate loaders will cost more. Unloading Flatcars. Table 7. Unloading Costs per M Board Feet Cost Dollars Item Flatcar $0. 127 Labor . 032 Forklift Total $0. 159 Total $1. 875 Boxcar -9- Table 5--(Chart) Cost $/M B.F. BREAK-EVEN COMPARISON HAND vs. MACHINE METHOD 5 4 BANDING AND WRAPPING 3 HAND MACHINE BREAK EVEN 1 HAND BANDING 41111M1M11142 MACHINE BANDING 12 10 4 8 6 ANNUAL PRODUCTION-MM B. F. 14 If the flatcar can be unloaded from both sides, the job can be done in 45 minutes. This requires use of a forklift with operator and a helper to remove the strapping. Wages cost $0. 127 per M board feet, and the forklift adds $0.032 for a total cost of $0. 159 per M board feet for unloading a flatcar of packaged lumber. Unloading Boxcars. The cost of unloading boxcars varies greatly according to the nature of the order. If it is highly mixed, as much as 3 days' time is needed for a two-man crew. If it is a straight car, two men can complete the job in 12 hours. It is assumed here that 15 hours are needed. Up to this point wage cost has been constant at $3. 40 per man-hour. In this instance we can assume wages to be $2, 50 per hour. This variation is predicated on the assumption that pickup labor will be procured at the local employment agency. At this rate the labor cost is $1. 875 per M board feet. The costs of supervision and moving lumber from the car siding are not included. Cost Summary and Comparison. The total marketing impact of packaged lumber involves both the producer and his customer. We will now look at these same costs to see how they affect the producer and the customer. Lumber Mill. The lumber producer is directly concerned with costs up to and including the loaded car. The total cost for loaded unpackaged lumber is $0. 98 per M less than for the machine-packaged lumber, and $1. 52 per M less than for the hand-packaged lumber. Recognizing this cost differential, the producer is adding a service charge for banding and wrapping lumber. Customer. The difference in cost for unloading packaged and unpackaged lumber is appreciable. The customer saves $1. 71 per M by using packaged lumber. Furthermore, it is estimated that the yard operator gains an additional saving of $1. 30 per M in storage and handling costs resulting from: less required storage space; outside storage reducing the need for sheds; no need to band units for on-site delivery. These savings amount to around $1.30 per M board feet. Hence the yard operator accrues a savings of around $3.00 per M board feet. Other Considerations: Advantages. 1. Speed and flexibility of loading. Loading packaged units permits orderly handling of shipments during periods of heavy demands when the stock is already in inventory. 2. Reduction of breakage loss. There is less chance for breakage when lumber is handled as a solid package. This pertains to the entire materials-handling procedure from the time the load is banded until it is opened up at the yard, factory, or building site. 3. Inventory procedure is simplified. Each unit has a prescribed volume for a given length; this eliminates the need for counting pieces. Also, while permitting a systematic method of storage it allows some flexibility because units can be stored where convenient with assurance that the contents will remain intact. 4. Order assembly. Order assembly is simplified because pieces of lumber do not have to be tallied. This is particularly advantageous when sales are made using unit volume for order lot sizes. 5. Protection in storage. The primary demand for wrapped lumber stems from the need to preserve quality during storage. Wrapping not only keeps the stock clean but it reduces absorption of moisture and maintains the moisture content at shipping date for an extended period. 6. Yard material handling, Improved material handling has become recognized as a necessity not only for the distribution center but for the retail yard as well. A fundamental concept of material handling efficiency is based on reducing the number of units or pieces to be handled. Packaged lumber meets this need. -10- 7. Reduction of yard area. Strapped lumber packages can be stacked safely as high as the forklift can reach. This higher stacking certainly reduces the amount of ground area needed for a given inventory volume. An added benefit from outside storage is that sheds are not needed. Property taxes are lowered bepanse of no sheds and less area. It is estimated that storage costs are reduced by two-thirds because of reduction of yard area; this is the biggest saving derived for the customer. 8. Pricing aid. Keeping the units intact until it is expedient to open them prevents the customer from picking through the pile to take out the best pieces, Where this picking over is permitted, the last portion usually consists of poorer material for the specific grade, and this leftover material becomes difficult to sell. Oftentimes this little dab is put into a lower grade at a reduced price or put into a "bargain pile" also at a lower price. Prevention of this is provided through banded stock. 9. On-site delivery simplified. It was previously mentioned that breakage is reduced by packaging lumber. Breakage reduction includes dumping loads at the building site. There is no scattering of pieces. Other Considerations: Limitations or Disadvantages. It might appear that banding is a panacea for all problems of lumber handling and marketing. Like anything else, it has its limitations or disadvantages. 1. Pattern stock. Although some pattern stock has been banded, it generally has been done on a limited or experimental basis, Where edges have been run to a pattern, damage can occur from side compression in the banding process. Also, as the load is vibrated in transportation, these edges tend to become alined. As this alinement occurs under pressure, the pattern work tears and the pieces come together. This reduces the strapping tension and increases the possibility of coring. 2. Lot volume. When the customer demands lot volumes not compatible with multiples of unit package volumes, packaging is prohibited. This limitation will relegate the highly mixed orders to boxcar loading with a probable resultant cost increase for that method of loading. 3. Claim adjustment. It was mentioned that banding lumber can reduce claims due to breakage. On the other hand, when claims are justified for other reasons, a serious delay in time can occur because the basis for claim will not be noticed until the package is opened up. This can be at the date of delivery or some months later. Packaging lumber is one step in improving the marketability of lumber. This study has shown why the customer wants it done. It is up to the producer to provide it. In the near future packaging will probably become a standard practice, much as banding studs has become. Then prices will probably be quoted on :a packaged basis with a deduction for nonpackaging. The price differential will be similar to straight car vs. mixed car prices. It behooves the operator to provide this service while, industry practice is to obtain a service charge to defray the cost.