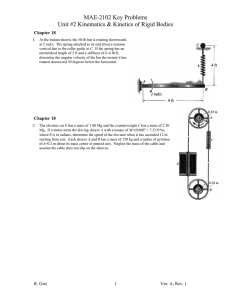

MK 7 AIRCRAFT RECOVERY EQUIPMENT CHAPTER 3

advertisement