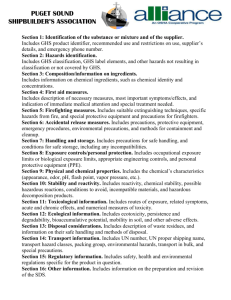

SAFETY AND HAZARDOUS MATERIALS CHAPTER 19

advertisement