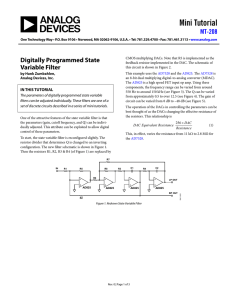

AD5757 Data Sheet Quad Channel, 16-Bit,

advertisement