2009 ] [

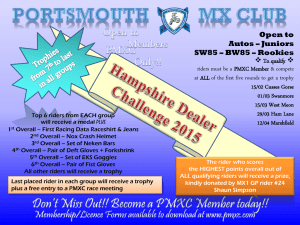

advertisement

![2009 ] [](http://s2.studylib.net/store/data/011680029_1-29b6deee4f339034cc51b0d375dc1440-768x994.png)