Efficient modeling of localized material failure by

advertisement

Preprint 2011

Efficient modeling of localized material failure by

means of a variationally consistent embedded strong

J. Mosler, L. Stanković and R. Radulović

Materials Mechanics

Helmholtz-Zentrum Geesthacht

discontinuity approach

This is a preprint of an article accepted by:

International Journal for Numerical Methods in Engineering (2011)

Efficient modeling of localized material failure by means of a

variationally consistent embedded strong discontinuity approach

J. Mosler & R. Radulović

L. Stanković

Materials Mechanics

Institute of Materials Research

Helmholtz-Zentrum Geesthacht

D-21502 Geesthacht, Germany

E-Mail: joern.mosler@hzg.de

Institute of Mechanics

Ruhr University Bochum

D-44780 Bochum, Germany

SUMMARY

This paper is concerned with a novel embedded strong discontinuity approach suitable for the analysis of material failure at finite

strains. Focus is on localized plastic deformation particularly relevant for slip bands. In contrast to already existing models,

the proposed implementation allows to consider several interacting discontinuities in each finite element. Based on a proper

re-formulation of the kinematics, an efficient parameterization of the deformation gradient is derived. It permits to compute

the strains explicitly which improves the performance significantly. However, the most important novel contribution of the

present paper is the advocated variational constitutive update. Within this framework, every aspect is naturally driven by energy

minimization, i.e., all unknown variables are jointly computed by minimizing the stress power. The proposed update relies

strongly on an extended principle of maximum dissipation. This framework provides enough flexibility for different failure

types and for a broad class of non-associative evolution equations. By discretizing the aforementioned continuous variational

principle, an efficient numerical implementation is obtained. It shows, in addition to its physical and mathematical elegance,

several practical advantages. For instance, the physical minimization principle itself specifies automatically and naturally the

set of active strong discontinuities.

1 INTRODUCTION

Traditionally, the modeling of cracks and shear bands is one of the most active research areas in (computational)

mechanics, see, e.g., [1, 2] and references cited therein for a comprehensive overview. Since the pioneering works

[3–5] have been published, particularly, so-called cohesive models have been frequently applied to the numerical

analysis of localized material failure. In contrast to standard stress-strain-based approaches, cohesive models

are governed by means of a traction-separation law. For instance, in case of brittle material failure, the normal

component of the traction vector is driven by the crack opening displacement (see [6]), while for ductile mode-II

or mode-III failure, a Schmid-type constitutive law connecting the resolved shear stress to the slip deformation is

often utilized, cf. [7].

Cohesive material models are usually based on a discontinuous approximation of the displacement field (strong

discontinuities) for capturing the material’s failure, although the separation can be modeled in a smeared fashion

by using an inelastic strain field as well, cf. [8]. Consequently, the discontinuities caused by cracks or shear bands

are explicitly and naturally included within this framework. In addition to this positive feature, such models show

numerous further advantages. For instance, they fulfill all criteria regarded as suitable for an efficient analysis of

failure in large-scale engineering structures as enumerated by Belytschko, Fish & Engelmann [9]. More precisely,

strong discontinuity approaches or cohesive models avoid the pathological mesh dependence in case of strainsoftening [10] and they account naturally for the multiscale character of material failure, i.e., the thickness of

the discontinuity is by definition zero and thus, it is infinitesimally smaller than the characteristic length scale of

the respective macroscopic structure. Accordingly, the idea is to incorporate the kinematics associated with the

small-scale (the softening zone) into a large-scale macroscopic material model. This is typical of most efficient

multiscale approaches, cf. [11–17], and permits to use relatively coarse macroscopic discretizations. This is a

significant difference compared to enhanced continuum models, such as non-local theories [18, 19] or gradient

enhanced models [20, 21] which require, at least, three to five finite elements across the thickness of the failure

zone resulting in high computational cost.

Clearly, for a realistic numerical analysis of material failure by means of strong discontinuity approaches the

kinematics of cracks or shear bands have to be approximated sufficiently accurately. For that purpose, two different

classes of finite element formulations can be utilized. The first of those falls into the range of interface elements,

cf. [22–24], where a jump in the deformation field is allowed to occur only at the boundaries between neighboring

1

2

J. Mosler, L. Stanković and R. Radulović

elements, while discontinuities can evolve arbitrarily within the second approach, i.e., displacement jumps are

also accounted for in the interior of finite elements, see [11, 14, 25–27]. Within the latter framework, a further

classification into models based on an element-wise approximation such as [11, 25, 26] (also known as Embedded

Strong Discontinuity Approaches), and methods relying on the eXtended Finite Element Method (X-FEM) or

Partition of Unity Finite Element Method (PU-FEM), cf. [14, 27] can be made. It bears emphasis that the X-FEM

[14, 27] and classical interface elements [22–24] are based on a continuous crack or shear band path representation.

More precisely, the field of displacement discontinuities is continuous at the element boundaries, e.g., the crack

width is approximated in a continuous fashion. By way of contrast, this is not the case for the Embedded Strong

Discontinuity Approach (ESDA), since it falls into the class of Enhanced Assumed Strain methods (EAS) and thus,

it relies on a local and incompatible enhancement, cf. [28]. Nevertheless, a continuous crack path is frequently

enforced within this framework as well, see [29, 30], though this is not required in general, cf. [31]. Further details

about the underlying kinematics and a comparison between the different models are omitted here. For a more

comprehensive overview, the reader is referred to [2, 32].

Within the present paper, focus is on a numerical implementation suitable for the analysis of numerous interacting and crossing cracks and shear bands in a fully three-dimensional setting at finite strains. Hence, several

simultaneously active discontinuities per finite element have to be taken into account. The aforementioned physical processes can be observed at almost every scale ranging from micro-defects to the macroscopic failure of

engineering structures. Consequently, the analysis of such phenomena is important for understanding the effect of

micro-defects on the resulting structural response (by using representative volume elements), but also for predicting the ultimate load of complex purely macroscopic mechanical systems. Though numerical models allowing for

a representation of an arbitrary crack path such as the X-FEM or the ESDA are very powerful for the simulation

of a restricted number of cracks or shear bands (also in the three-dimensional case), their application to problems

showing large numbers of simultaneously active discontinuities has not been demonstrated yet. More precisely,

an algorithm suitable for tracking each of those numerous discontinuities individually in a fully three-dimensional

setting has not been reported in the literature so far.

Multiple discontinuities can naturally be modeled by using classical interface elements. Unfortunately, such

formulations show a pronounced mesh bias, cf. [33], and thus, they have to be combined with adaptive strategies,

see [34–36]. Moreover, within interface formulations the field of displacement discontinuities is approximated in

a continuous fashion (as in the X-FEM) and hence, they require a modification of the global structure of the finite

element code resulting in higher numerical cost. The brief analysis given here points out the need for a novel strong

discontinuity approach for the analysis of numerous interacting and crossing cracks or slip bands. In the present

paper, an approach based on the ESDA is employed. For allowing interacting and crossing failure surfaces, several

discontinuities are considered in each finite element. Since this leads to increased numerical cost, efficiency of

the kinematics is of utmost importance. For that purpose, a novel parameterization of the deformation gradient is

elaborated which avoids the computation of the inverse of a 4th-order tensor and thus, it increases the numerical

performance significantly. A further boost of the efficiency is obtained by assuming the slip bands or the cracks

to be aligned with the facets of the underlying finite element discretization. Here, a strong link to the kinematics

of classical interface formulations exists. However, in sharp contrast, the topology of the mesh remains fixed, i.e.,

no duplication of nodes is required and the global finite element level is not affected. Evidently, this procedure

guarantees a continuous approximation of the crack path. The only shortcoming of this novel approach is that it

entails a certain mesh bias. Fortunately, this bias is not very pronounced as demonstrated by means of selected

numerical examples. Furthermore, if desired, it can be further reduced by using adaptive strategies, see [34–36],

or by other advanced methods which will also be discussed in the present paper.

The second requirement for the numerical analysis of material failure is a physically sound constitutive model.

Here, focus is on plasticity-based material laws. Such laws are particularly important for the modeling of slip

bands. A critical literature review reveals that most of the interface models are postulated in an ad-hoc manner and

not derived consistently from the principles of thermodynamics. For instance, the traction vector T is frequently

assumed to depend explicitly on the displacement discontinuity via T = T ([[u]]). Clearly, such a model is, at best,

Cauchy-elastic, cf. [37, 38]. Thus, it does neither guarantee a vanishing dissipation in case of elastic unloading nor

a truly positive dissipation in case of irreversible processes. For this reason, only thermodynamically consistent

models are considered in what follows. They are usually based on the Helmholtz energy of the interfaces (cracks

and shear bands) and evolution equations are derived by means of the second law of thermodynamics. Taking

large plastic deformations into account, such models can be found, for instance, in [2, 7, 39, 40]. Relatively recently, combinations with ductile damage evolution, rate effects and temperature effects were proposed in a series

of papers by Fagerström & Larsson, see [41–44]. Based on the cited publications, a class of non-associative plasticity models is elaborated in the present paper. It can naturally enforce certain failure modes (such as mode-II or

mode-III) and covers, amongst others, an anisotropic Drucker-Prager model. In sharp contrast to existing cohesive

models, the novel approach proposed here is fully variational. More precisely, every aspect is driven by energy

minimization, i.e., the unknown displacement discontinuity and the internal variables are jointly computed by min-

A variationally consistent embedded strong discontinuity approach

3

imizing the stress power. For providing enough flexibility to account even for non-associative evolution equations,

the flow rule and the evolution equations are enforced a priori by utilizing a convenient re-parameterization. The

dissipation functional can be chosen independently of those equations. The resulting variational principle can thus

be understood as a novel, extended principle of maximum dissipation. A similar concept was recently developed

in [45, 46] for classical plasticity models (stress-strain-based). By discretizing this variational principle, an efficient numerical implementation is derived. It can be applied to a broad range of, even non-associative, plasticity

models. Furthermore, it accounts for several discontinuities within each finite element. In contrast to implementations based on a modified return-mapping scheme, no artificial search strategy for determining the active internal

surfaces is required. This active set is naturally controlled by energy minimization. It will be shown that the advocated algorithmic formulation is formally identical to that for standard (continuous deformation) material models,

cf. [16, 45, 47, 48].

The paper is organized as follows: First, the kinematics associated with material failure is discussed in Section 2. For that purpose, the fundamentals of the Embedded Strong Discontinuity Approach are briefly summarized. Subsequently, an efficient parameterization of the deformation gradient is elaborated and finally, the

formulation is generalized to encompass several interacting discontinuities. The constitutive models are addressed

in Section 3. While a standard hyperelastic model for the bulk material is briefly described in Subsection 3.1,

the material response of slip bands and cracks is discussed in Subsection 3.2. Subsection 3.2 represents the main

part and contains the most important novel contribution of the present paper. Starting by summarizing some general principles for the derivation of interface models in Paragraph 3.2.1, a class of constitutive laws is developed

in Paragraph 3.2.2. In Paragraph 3.2.3, this class of prototype models is recast into a variationally consistent

framework. Within this novel variational method, everything is consistently driven by energy minimization, i.e.,

the internal variables and the deformation follow naturally from energy minimization. The respective numerical

implementation is elaborated in Section 4 and the performance of the resulting scheme is carefully analyzed in

Section 5.

2 KINEMATICS OF EMBEDDED STRONG DISCONTINUITIES

This section is concerned with the kinematics induced by strong discontinuities. More precisely, focus is on a

certain approximation of discontinuous displacement fields originally advocated in [11] (see also [49–51]). In

contrast to classical interface formulations [22] and eXtended Finite Element Methods (X-FEM, cf. [14, 52]), the

considered approximation of the deformation field is based on the Enhanced Assumed Strain concept (EAS) [28]

resulting in a globally incompatible displacement representation. As a result, this scheme is often referred to as

embedded strong discontinuity approach (ESDA).

First, the kinematics associated with a single discontinuity is presented in Subsection 2.1. While the fundamentals are addressed in Paragraph 2.1.1, a novel re-formulation of the discontinuous deformation mapping is

elaborated in Paragraph 2.1.2. Though it is equivalent to the original description, the new equation is numerically

more efficient. Finally, the extensions necessary for several possibly interacting and crossing discontinuities are

discussed in Subsection 2.2.

2.1 Single strong discontinuity

2.1.1 A concise review of the fundamentals

The fundamentals of the kinematics characterizing the ESDA (Embedded Strong Discontinuity Approach) are

briefly summarized in this paragraph. Further details and mathematical aspects can be found, e.g., in [2, 32].

Following [11, 49, 51], the discontinuous deformation mapping associated with a crack or a shear band ∂s Ω is

approximated by

u = û + [ u]] (Hs − ϕ), with û, ϕ ∈ C ∞ .

(1)

In Eq. (1), û represents the standard, continuous displacement field, [ u]] denotes the displacement discontinuity

at ∂s Ω, Hs is the Heaviside function with respect to the singular surface ∂s Ω and ϕ, not to be confused with the

deformation mapping ϕ, is a smooth ramp function necessary to prescribe the boundary conditions in terms of

û (see [51]). Clearly, considering a single finite element crossed by a discontinuity ∂s Ω, implies the partition of

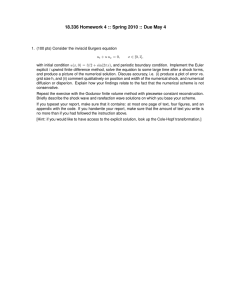

its domain Ω into Ω = Ω− ∪ ∂s Ω ∪ Ω+ , see Fig. 1. Here, the normal vector N defining locally the topology of

∂s Ω points into Ω+ . With such notations, the ramp function ϕ of a certain finite element is designed by using the

standard interpolation functions Ni associated with node i as

n

ϕ=

Ω+

X

i=1

Ni

(2)

4

J. Mosler, L. Stanković and R. Radulović

∂s Ω

N Ω

Ω+

F

[ u]]

Ω−

F̄

F̃

J

Figure 1: Kinematics induced by strong discontinuities: The deformation can be locally multiplicatively decomposed into a (standard) continuous deformation F̄ and an additional mode related to the kinematics of material

failure F̃ , cf. [7].

where the summation in Eq. (2) is to be performed over all shape functions corresponding to nodes belonging to

the closure of Ω+ , cf. [32, 49].

By applying the generalized derivative to the Heaviside function, i.e., DHs = N δs (see [53, 54]), the deformation gradient is computed as

F =1+

∂ [ u]]

∂ϕ

∂ û

+

(Hs − ϕ) + [ u]] ⊗ N δs − [ u]] ⊗

∂X

∂X

∂X

(3)

with δs representing the Dirac-delta distribution. In what follows, a spatially constant approximation of the displacement discontinuity is chosen. Consequently, GRAD [ u]] = 0. More general interpolations can be found, for

instance, in [55]. With this assumption, the only spatially varying variable in Eq. (3) is the continuous displacement

field û. In line with the standard (continuous) finite element method, û is defined by means of shape functions,

i.e.,

nX

node

(4)

Ni ûei

û =

i=1

and continuity at the element boundaries is enforced by a standard assembling procedure. As a result, û is globally

conforming and continuous. In Eq. (4), ûei are the displacements at node i. Following [7, 56], Eq. (3) can be

rewritten into the equivalent multiplicative decomposition

F = F̄ · F̃ ,

F̄

F̃

with

=

=

1 + GRADû − [[u]] ⊗ GRADϕ

−1

1 + J ⊗ N δs ,

J := F̄ · [ u]] .

(5)

Here, the assumption GRAD [ u]] = 0 has been made again. According to Eq. (5), F̄ is the regularly distributed

part of F , while F̃ is associated with the singular distribution resulting from the displacement discontinuity, see

Fig. 1. In Eq. (5), J denotes the material counterpart of the displacement discontinuity, i.e., J is the pull-back of the

spatial vector [ u]] and belongs to the intermediate configuration implied by the multiplicative decomposition (5)1 .

Representation (5) is particularly convenient in case of plastic deformation. Further details are omitted here. They

can be found in [2, 32].

2.1.2 An equivalent, more efficient description

In what follows, the displacement discontinuity ([[u]] or J ) is assumed to be associated with purely irreversible

deformations. Furthermore and fully analogously to classical plasticity theory (continuous deformation), its evolution is postulated to be of the type J̇ = f (•). It bears emphasis, that such an evolution equation automatically

fulfills the principle of material objectivity, since J belongs to the intermediate configuration. Thus, the strains in

Ω± = Ω− ∪ Ω+ will be computed from

F̄ = 1 + GRADû − F̄ · J ⊗ GRADϕ.

(6)

As a result, for elastic elastic unloading (or for an elastic trial state), Eq. (6) reads

tr

tr

F̄ n+1 = F̂ n+1 − F̄ n+1 · J n ⊗ GRADϕ,

F̂ := 1 + GRADûn+1

(7)

A variationally consistent embedded strong discontinuity approach

5

tr

where the indices n and n + 1 correspond to pseudo times tn and tn+1 . Though being linear in F̄ n+1 , Eq. (7)

is implicit. According to [39], for a known continuous field û (which is the case in displacement-driven finite

element formulations), the straightforward solution of Eq. (7) is given by

tr

F̄ n+1 = A−1 : F̂ n+1 ,

Aikpq := Iikpq + [Iijpq Jj GRADϕk ]|tn .

(8)

As evident, the computation of the inverse of the 4th-order tensor A is numerically very costly. Since this inverse

has to be computed several times within the algorithm, the resulting performance of the scheme is relatively poor.

For this reason, Eq. (6) will be re-written into an equivalent, but numerically more efficient, counterpart.

For re-formulating Eq. (6), the deformation gradient F̄ is simply multiplied by the displacement discontinuity

J yielding

F̂ · J

F̄ · J = F̂ · J − F̄ · J (GRADϕ · J ) ⇒ F̄ · J =

.

(9)

1 + GRADϕ · J

Hence, Eq. (9)2 implies F̄ · J || F̂ · J , cf. [40]. Inserting Eq. (9)2 into Eq. (6), leads finally to

F̄ = F̂ −

1

F̂ · J ⊗ GRADϕ.

1 + GRADϕ · J

(10)

Eq. (10) is better suited than Eq. (6) for, at least, two reasons. First, in case of elastic loading, Eq. (10) reads

F̄ n+1 = F̂ n+1 −

1

F̂ n+1 · J n ⊗ GRADϕ.

1 + GRADϕ · J n

(11)

Consequently, the strains F̄ n+1 can be computed directly, without requiring the inverse of a 4th-order tensor.

Thus, the resulting algorithm is significantly more efficient than that previously proposed in [39]. Secondly, for

slip bands characterized by mode-II or mode-III failure, J · N = 0 holds. Hence,

F̄ · J = F̂ · J

and F̄ = F̂ − F̂ · J ⊗ GRADϕ.

(12)

While Eq. (12)2 is a further simplification of Eq. (11), Eq. (12)1 implies that the push-forwards of the material

displacement jump with respect to F̂ and F̄ are identical. A similar relation for the push-forward of a tangent

vector was derived in [40]. More precisely, the relation

F̂ · M

F̄ · M

=

,

||F̄ · M ||

||F̂ · M ||

M ·N =0

(13)

was derived in [40]. It bears emphasis that Eq. (12)1 encompasses Eq. (13) and thus, it is more general. Furthermore, since in displacement-based finite element formulations û and F̂ are usually known, Eq. (12)1 yields the

convenient relation

[ u]] = F̄ · J = F̂ · J .

(14)

Eq. (14) is directly related to the assumption GRAD [ u]] = 0.

Remark 1 According to [57], the embedded strong discontinuity approach shares some similarities with fracture

energy models based on a characteristic length lc . Conceptually, such a length scale smears the displacement

discontinuity over the respective finite element, i.e., it transforms a deformation jump into an equivalent inelastic

strain. In [8], a characteristic length has been proposed which can be re-written as lc = (N ·GRADϕ)−1 , cf. [57].

Thus, if the ramp function ϕ is not chosen properly, lc can be negative giving unphysical results. This is particular

true in a three-dimensional setting. As a result, some authors elaborated ideas for selecting the optimal ϕ. For

instance, the method presented in [31] is equivalent to minimizing the length scale lc . Physically speaking, this

strategy reduces artificial smearing of the localized deformation. In the present paper, the discontinuity is assumed

to be parallel to the facets of the considered finite element. Hence, lc = (N · N ||GRADϕ||)−1 = 1/||GRADϕ|| >

0. Thus, the aforementioned numerical problems cannot occur.

2.2 Multiple strong discontinuities

Conceptually, the modifications of the kinematics in case of multiple simultaneously active strong discontinuities

are relatively straightforward. For linearized kinematics, first ideas can be found in [58].

Starting from Eq. (6), a superposition of ns displacement jumps leads to a deformation gradient in Ω± of the

type

ns

X

F̄ = F̂ − F̄ ·

J (β) ⊗ GRADϕ(β) ,

F̂ = 1 + GRADû.

(15)

β=1

6

J. Mosler, L. Stanković and R. Radulović

Figure 2: Continuity of the singular surface ∂s Ω across finite elements: a) stochastically generated discontinuities;

b) discontinuities parallel to the element facets (edges in a two-dimensional setting)

Alternatively, extending Eq. (12)2 which holds for slip planes (J · N = 0) yields

F̄ = F̂ − F̂ ·

ns

X

β=1

J (β) ⊗ GRADϕ(β) .

(16)

Clearly, both superpositions (15) and (16) are physically reasonable. Unfortunately and in contrast to a single

discontinuity, Eqs. (15) and (16) are not equivalent, even if mode-II or mode-III failure is considered. A mathematical analysis of the difference between Eq. (15) and Eq. (16) could be performed by rewriting Eq. (15) into

F̄ = A−1 : F̂ and Eq. (16) into F̄ = Ã−1 : F̂ and finally checking ||A − Ã−1 ||. Such an analysis is beyond

the scope of the present paper. Instead, numerical experiments have been considered. More precisely, it turned

out within all computations that both approximations predict almost identical results, cf. [59]. For this reason, the

numerically more efficient formulation (16) will be applied in what follows (compare to Paragraph 2.1.2).

So far, the normal vector N defining the local topology of the cracks or the slip bands has been assumed as

known. Clearly, the position and orientation of the discontinuities depend on the considered material as well as on

the loading state. In case of a single discontinuity per element, different approaches can be found in the literature.

They can be subdivided into two classes: methods based on a continuous crack path such as [29, 30] and those

without enforcing crack path continuity, cf. [31]. For a comprehensive overview, the interested reader is referred

to [32]. Strictly speaking, a continuous crack path means that ∂s Ω is approximated in a continuous fashion. The

field of displacement discontinuities is in any case discontinuous at the element boundaries within the framework

of embedded strong discontinuity approaches.

In the present paper, a numerical method without explicitly enforcing crack path continuity is chosen for

two reasons. First, within each finite element up to four crossing displacement jumps are allowed to propagate

(tetrahedron element with four facets). For such a case, the design of a continuous crack path is very complex and

a subject of its own. Second and even more importantly, the novel approach proposed here should be applicable

to mechanical problems showing a large number of simultaneously active discontinuities such as in fragmentation

processes, see Subsections 5.1.3 and 5.2.2. To the best knowledge of the authors, such complex problems have

not been analyzed numerically yet by an embedded strong discontinuity approach with a continuous crack path

representation.

Even if the crack path is modeled in a discontinuous fashion, the computation of four different normal vectors

within a certain finite element is cumbersome. Usually, certain conditions such as orthogonality are enforced,

cf. [32]. Here, and in line with classical interface formulations it is assumed that the crack surfaces are aligned

with the facets or the edges of the respective finite element, i.e., the topology of possible discontinuities is a priori

known. In contrast to interface elements, the topology of the mesh remains, however, fixed, i.e., no duplication

of nodes is required. Clearly, this procedure guarantees a continuous approximation of the crack path, see Fig. 2.

Furthermore, an arbitrary single displacement jump can be approximated reasonably by a linear combination of

the facet modes. It turns out that the induced mesh bias is not very pronounced an can be effectively reduced

(see Subsection 5.2.1). Alternatively, adaptive strategies such as those in [34–36] can be applied. However, such

methods are beyond the scope of the present paper.

Summarizing the aforementioned discussion, the orientation of the normal vectors within a certain finite element is a priori assumed to be of the type

N (i) = GRADϕ(i) /||GRADϕ(i) ||.

(17)

Considering (linear) tetrahedron elements, two different failure modes are possible (two different types of ramp

functions ϕ(i) ): one node in Ω+ (or equivalently, three nodes), or two nodes in Ω+ . While the first of those is

associated with a facet, the latter corresponds to an edge.

A variationally consistent embedded strong discontinuity approach

7

In addition to reducing the numerical cost for computing the unknown orientation of N , the proposed method

shows two further advantages. First, it results in a symmetric tangent stiffness matrix which opens up the possibility

of deriving variationally consistent update schemes. Such a method will be developed in Subsections 3.2.3 and 4.2.

Second, as will be shown in Section 4, the numerical implementation avoids local snap-back problems as reported

in [60] (originally, the authors call it loss of uniqueness, cf. [58]).

3 CONSTITUTIVE EQUATIONS

This section is concerned with constitutive models describing the material response. While Subsection 3.1 is associated with points belonging to Ω± , i.e., the bulk material, Subsection 3.2 is related to traction-separation-laws.

First, the fundamentals of interface models are briefly summarized in Paragraph 3.2.1. Subsequently, a physically

sound class of constitutive models is presented in Paragraph 3.2.2. Finally, a novel variationally consistent approach is described in Paragraph 3.2.3. In line with so-called variational constitutive updates for classical stressstrain-based material models (see [16, 45, 47, 48]), all state variables, together with the unknown deformation

mapping, follow jointly from minimizing a suitable energy functional.

3.1 Constitutive model for the bulk material

Since the deformation gradient is regularly distributed in the bulk material (F = F̄ holds), standard stress-strainbased continuum models can be applied. For the sake of simplicity, an elastic response is assumed here. However,

other, more complex constitutive models can be easily incorporated as well.

Following the fundamentals of hyperelasticity and objectivity, a stored energy functional of the type

Ψreg = Ψreg (C̄),

C̄ := F̄

T

· F̄ = C

∀X ∈ Ω±

(18)

is postulated. By utilizing the standard Coleman & Noll procedure [61–63], the well-known stress response

τ = F̄ · S · F̄

T

S = 2 ∂C̄ Ψreg ,

and

(19)

is computed. Here, S denotes the second Piola-Kirchhoff stress tensor and τ are the Kirchhoff stresses. In the

numerical analyses presented in Section 5, a neo-Hooke-type energy functional Ψreg of the type

1

λ

J2 − 1

−

+ µ ln (J) + µ trC̄ − 3

(20)

Ψreg (C̄) = λ

4

2

2

is adopted, where J, tr, λ, µ are the determinant of the deformation gradient F̄ , the trace operation and the Lamé

constants.

3.2 Constitutive model for material interfaces

3.2.1 Fundamentals of traction-separation laws

In contrast to the bulk material, dissipative processes are taken into account within the interface ∂s Ω. More precisely, it is assumed that the localized deformations J are of purely irreversible, plastic nature. Clearly, other

mechanical processes such as those related to an elastic or damage-induced response can be modeled in a similar

fashion, cf. [13, 64, 65]. Assuming the interface model to be independent of the bulk material law, a stored-energy

functional of the type

Ψ(C̄, J , α) = Ψreg (C̄) + Ψsing (α) δs

(21)

is considered, cf. [39]. The localized nature of the deformation is reflected by the Dirac-delta distribution, see. [32,

51, 64, 66–68]. In Eq. (21), α is a displacement-like internal variable containing, among others, the displacement

discontinuity J .

The coupling of the constitutive model for points belonging to Ω± and that corresponding to X ∈ ∂s Ω is

provided by the condition of traction continuity, i.e,

T ± − T s = 0,

∀X ∈ ∂s Ω.

(22)

Here, T ± denotes the limits of the traction vector T at the negative and the positive boundary of the discontinuity

and T s is the traction vector within the discontinuity. Since the identity T ± = P ± · N holds (P is the first

Piola-Kirchhoff stress tensor), T ± depends on the bulk’s material model, while T s results from the interface law.

Accordingly, Eq. (22) represents a physically sound coupling condition. It is noteworthy that due to the underlying

8

J. Mosler, L. Stanković and R. Radulović

Petrov-Galerkin discretization of the ESDA, this compatibility condition is not a priori included, but has to be

enforced explicitly, cf. [40, 69].

For developing constitutive models capturing irreversible mechanical processes, the constraints imposed by the

second law of thermodynamics have to be fulfilled. For that purpose, the dissipation D = P : Ḟ − Ψ̇ is computed.

After a straightforward calculation and after inserting the elastic response (19), the reduced dissipation inequality

is finally obtained as

h

i

D = T̄ · J̇ + q · α̇ δs ≥ 0,

q := −∂α Ψsing ,

T̄ := Σ · N ,

Σ := C̄ · S.

(23)

Here, Σ are the Mandel stresses, q is a stress-like internal variable conjugate to α, T̄ is the push-forward of the

traction vector T to the intermediate configuration and the superposed dot represents the material time derivative.

Further details, including the analogy to crystal plasticity theory, can be found in [39].

By exploiting the analogous structure between Eq. (23) and that of standard (continuous deformation) finite

strain plasticity theory, the space of admissible stresses

ET̄ := (T̄ , q) ∈ R3 × Rn | φ(T̄ , q) ≤ 0

(24)

is introduced. In Eq. (24), T̄ is the traction vector at the singular surface obtained from the bulk’s model, i.e., the

± sign has been dropped for the sake of conciseness. It bears emphasis that for the special choice, q = T̄ s and

φ(T̄ , q) = ||T̄ − q||, φ = 0 is equivalent to the condition of traction continuity. Consequently, the concept of

admissible stresses encompasses the condition of traction continuity leading to a more general formulation. For

this reason, it is adopted in what follows. More details can be found in [39].

Based on Ineq. (23) and Eq. (24), physically sound evolution equations can be derived. More precisely, applying the postulate of maximum dissipation

compute: min L,

with

T̄ ,q,λ

L(T̄ , q, λ) := −D + λ φ δs .

(25)

yields

J̇ = λ ∂T̄ φ,

α̇ = λ ∂q φ.

(26)

In line with standard plasticity theory, the plastic multiplier λ is computed from the consistency condition φ̇ = 0.

More general non-associative evolution equations can be derived by means of two additional convex potentials: a

plastic potential g = g(T̄ , q) and a hardening/softening potential h = h(T̄ , q), i.e.,

J̇ = λ ∂T̄ g,

α̇ = λ ∂q h.

(27)

3.2.2 A prototype model

In what follows, a class of constitutive models characterized by yield functions of the type

φ = T̄ eq (T̄ ) − qi (αi ) − q0eq

(28)

will be considered. Accordingly, φ depends on an equivalent stress measure T̄ eq which is assumed to be a positively

homogeneous function of degree one. For associative evolution equations, the dissipation corresponding to Eq. (28)

reads in this case

D = λ q0eq δs ≥ 0.

(29)

Hence, D is indeed positive and equally importantly, it can be computed in closed form. For several applications,

it is convenient to decompose the traction vector into a normal and a shear part, i.e.,

T̄N := T̄ · N ,

T̄ S := T̄ − T̄N N .

(30)

Based on this decomposition, the equivalent stress measure can be additively split in a similar fashion:

T̄ eq (T̄ ) = T̄Neq (T̄N ) + T̄Seq(T̄ S ).

(31)

Again, T̄Neq and T̄Seq are postulated to be homogeneous functions of degree one. If T̄Neq and T̄Seq are positively

homogeneous of degree n and m, a positively homogeneous equivalent stress T̄ eq of degree one can be defined as

q

q

(32)

T̄ eq (T̄ ) = n T̄Neq(T̄N ) + m T̄Seq(T̄ S )

A variationally consistent embedded strong discontinuity approach

9

cf. [45]. Therefore and without loss of generality, the order of T̄Neq and T̄Seq is assumed to be one. The aforementioned class of yield functions is very broad and contains many important constitutive models. For instance, by

setting

1 p

T̄ S · H · T̄ S

(33)

φN (T̄N ) = κ T̄N ,

φS (T̄ S ) =

2

an anisotropic Drucker-Prager model suitable for the analysis of slip bands is obtained. Here, H is a tensor

describing the material anisotropy. By way of contrast, the case TSeq = 0 corresponds to a Rankine-type yield

function representing an admissible choice for the modeling of cracks.

The class of prototype models described here is completed by suitable evolutions equations. While such equations can be derived in a relatively straightforward manner for mixed-mode failure, slip bands require further

attention, i.e., mode-II or mode-III failure has to be enforced explicitly in that case (J · N = 0). Clearly, this

requires a non-associative constitutive law. A physically sound method for deriving such a law is given by the

framework of generalized standard materials, cf. [70, 71]. Accordingly, physically sound evolution equations

(D ≥ 0) can be developed by using a convex plastic potential g and a convex hardening/softening potential h. Obviously, if g depends only on the shear components of the traction vector T̄ , mode-I failure is naturally excluded.

For this reason, a plastic potential of the type

g = h = T̄Seq(T̄ S ) − qi (αi ) − q0eq .

(34)

is suitable for the analysis of slip bands. Eq. (34) leads finally to the evolution equations

J̇ = λ

∂ T̄Seq

,

∂ T̄

α̇ = −λ

(35)

and the dissipation is computed as

φ=0

D = λ (T̄Seq − qi ) δs = λ (q0eq − T̄Neq) δs .

(36)

In contrast to their associative counterparts, non-associative evolution equations entail an additional non-constant

term in the dissipation inequality (compare to Eq. (29)).

Remark 2 In the present paper, only isotropic hardening/softening models are considered. However, it is noteworthy that linear kinematic hardening of Prager-Ziegler-type can easily be included as well. For a geometrically

linearized framework, further details can be found in [65].

Remark 3 For a function T̄ eq(T̄ ) being positively homogeneous of degree one, T̄Seq (T̄ ) = ∂T̄ g · T̄ is fulfilled (see

Eq. (34)). Differentiating this identity once again yields

∂T̄2 g · T̄ = 0.

(37)

This identity which represents a compatibility condition between the stress vector and the flow direction will be

utilized for checking consistency of the variational constitutive updates presented in the next section.

3.2.3 Variational principles for traction-separation laws

In what follows, the constitutive model presented in the previous section, is recast into a variationally consistent

framework. Within this framework all state variables, together with the unknown deformation mapping, follow

jointly from minimizing an incrementally defined energy potential. In case of classical (continuous) associative

finite strain plasticity, such methods have been proposed in [16, 45, 47], while for non-associative evolution equations first ideas can be found in [46]. Though variational constitutive updates show several advantages compared

to other (standard) approaches such as the existence of a natural distance or the possibility of applying state-ofthe-art optimization schemes, they have not been developed yet for problems showing strong discontinuities, i.e.,

for cohesive traction-separation laws. In this paragraph, such a variationally consistent framework is elaborated.

It can be applied to a broad range of different constitutive models. First, the associative case is considered. Subsequently, an enhanced postulate of maximum dissipation is advocated allowing to account for non-associative

evolution equations as well. Several simultaneously active and possibly intersecting discontinuities are considered

within all derivations.

Conceptually and analogously to [16, 45, 47], the novel variational framework is based on minimizing the

stress power Ẽ = P : Ḟ = Ψ̇ + D. However and in contrast to the continuous case, the Helmholtz energy

Ψ contains, in addition to the standard regularly distributed part, a Dirac-delta distribution. The same holds for

10

J. Mosler, L. Stanković and R. Radulović

the dissipation. Starting with the constitutive framework discussed in the previous paragraph and considering ns

possibly interacting and crossing strong discontinuities, the stress power is given by

Ẽ(ϕ̇, J̇

(1)

(1)

, α̇

(1)

, T̄

,q

(1)

, . . . , J̇

(ns )

(ns )

, α̇

, T̄

(ns )

,q

(ns )

+

) = Ψ̇reg (ϕ̇) + c

ns

X

i=1

with χ(i) = χ(i) (T̄

(i)

ns

X

(i)

Ψ̇sing (α̇(i) ) δs(i)

i=1

(i)

D (J̇

(i)

(i)

, α̇ , T̄

(i)

(i)

,q ) +

ns

X

χ

(i)

δs(i)

i=1

!

(38)

,

, q (i) ) being the characteristic function of the space of admissible stresses ET̄ (i) , i.e.,

χ(i) = χ(i) (T̄

(i)

, q (i) ) =

(

(i)

0 , if (T̄ , q (i) ) ∈ ET̄ (i)

(i)

∞ , if (T̄ , q (i) ) ∈

/ ET̄ (i) .

(39)

In Eq. (38), c is a constant parameter related to the relative position (or area) of the discontinuity within the

respective finite element. It can be considered as c = 1 at the moment. Its precise physical interpretation will

be explained later. According to Eq. (38), χ(i) vanishes for admissible stresses and Ẽ represents indeed the stress

power. Inadmissible states are penalized by χ(i) = ∞ and thus, they are a priori excluded, if minimization of Ẽ is

the overriding physical principle. In line with [16, 45, 47], the postulate of maximum dissipation (maximization of

Ẽ with respect to the stress-like variables) is applied next, yielding

E(ϕ̇, J̇

(1)

(1)

, α̇

, . . . , J̇

(ns )

(ns )

, α̇

) = Ψ̇reg (ϕ̇) + c

ns

X

i=1

(i)

Ψ̇sing (α̇(i) )

δs(i)

+

ns

X

χ

∗(i)

δs(i)

i=1

!

.

(40)

Here and henceforth, χ∗(i) is the Legendre transformation of χ(i) , cf. [72]. Physically speaking, χ∗(i) is the

dissipation, provided only admissible states and associative evolution equations are considered. Consequently, E is

still the stress power, but now as a function of displacement-like variables only. As shown in Paragraph 3.2.2 (see

Eq. (29)), for associative evolution equations based on a positively homogeneous yield function, χ∗(i) is obtained

eq(i)

in closed form as χ∗(i) = λ(i) q0

≥ 0. Though such an assumption is usually made, it is not mandatory, cf.

[16, 45, 47].

Similarly to [16, 45, 47], it can be shown that the minimizers of E are equivalent to the underlying associative

flow rule and the corresponding evolution equations. More precisely, they follow naturally from the locally defined

problem

(1)

(ns )

(1)

(ns )

(J̇ , α̇(1) , . . . , J̇

, α̇(ns ) ) = arg inf E(ϕ̇, J̇ , α̇(1) , . . . , J̇

, α̇(ns ) )

.

(41)

ϕ̇=const

Since variational principle (41) is not standard and furthermore, it depends on the parameter c, its consistency will

be explicitly proved. However, a more suitable re-parameterization of the functional E is given first.

Although the solution of Eq. (41) looks straightforward, it bears emphasis that several highly non-linear constraints related to the flow rule and the evolution equations have to be included. For instance, self-penetration

has to be avoided a priori. Since only isotropic hardening/softening models are considered in the present paper,

α(i) = α(i) is scalar-valued and thus, the respective constraint can be enforced trivially, i.e., α̇(i) = −λ(i) ≤ 0.

Consequently, the only non-trivial constraint is associated with the flow rule

J̇

(i)

= λ ∂T̄ (i) φ(i) ,

(42)

or more precisely, it is related to the flow direction. In what follows, two convenient parameterizations of the flow

direction will be proposed.

For elaborating suitable parameterizations of the flow direction, the underlying ideas are explained first by

means of a von Mises model defined by the yield function φ = ||T̄ S || − q0eq . Without loss of generality, hardening

or softening can be neglected, since those mechanisms do not affect the flow rule. The generalizations necessary

for other flow rules will be discussed subsequently. Evidently, in case of a von Mises-type yield function, the

resulting flow direction for discontinuity i reads

(i)

(i)

∂T̄ (i) φ

with

(i)

T̄ S

=

T̄ S

(i)

n

o

∈ M(i) := M (i) M (i) · N (i) = 0, M (i) : M (i) = 1

||T̄ S ||

(i)

:= 1 − N (i) ⊗ N (i) · T̄ .

(43)

A variationally consistent embedded strong discontinuity approach

11

Accordingly, a straightforward three-dimensional parameterization of the flow direction depending on a so-called

˜ (i) 6= T̄ (i) is given by

pseudo-stress vector T̄

q

˜ (i) = 3.

˜ (i) , dim T̄

˜ (i) · (1 − N (i) ⊗ N (i) ) · T̄

˜ (i) , λ(i) = √1

T̄

λ(i) ∂T̄ (i) φ(i) = 1 − N (i) ⊗ N (i) · T̄

b

(44)

Alternatively, an equivalent two-dimensional parameterization is obtained by enforcing the orthogonality between

˜ (i) and N (i) a priori, i.e.,

T̄

q

1

(i)

(i)

(i)

(i)

(i)

(i)

˜ (i) · T̄

˜ (i) , dim T̄

˜ (i) = 2.

˜

˜

T̄

(45)

λ ∂T̄ (i) φ = T̄ , with T̄ · N = 0, λ = √

b

The coefficient b in Eqs. (44) and (45) is usually non-constant. It can be computed by calculating the norm of

Eqs. (44)1 or Eqs. (45)1 yielding

(46)

b = ∂T̄ (i) φ(i) · ∂T̄ (i) φ(i) .

Consequently, for a von Mises-type or an isotropic Drucker-Prager-type model b is constant. More precisely, in

case of von Mises plasticity, b = 1.

Clearly, Eqs. (44) and (45) are suitable parameterizations of the flow rule. However, in many cases, a decomposition into an amplitude and into a direction is more convenient. For that purpose, Eq. (44) is slightly modified

leading to

˜ (i)

1 − N (i) ⊗ N (i) · T̄

˜ (i) ∈ R3 .

T̄

(47)

∂T̄ (i) φ(i) ∈

˜ (i) ||

|| 1 − N (i) ⊗ N (i) · T̄

As a result, the flow rule (direction) can be parameterized as

o

n

˜ (i)

∂T̄ (i) φ(i) = ∂T̄ (i) g (i) ∈ ∂T̄ (i) g (i) ˜ (i) T̄

∈ R3 .

T̄

(48)

Interestingly, this parameterization of the flow direction is always meaningful. It even applies to non-associative

evolution equations or anisotropic plastic potentials. According to Eq. (48), the natural underlying idea is that

the space of admissible flow directions is obtained simply by evaluating the flow rule for all admissible stress

˜ (i) 6= T̄ (i) is referred to as the pseudo stress vector. Obviously, it

states. This interpretation explains that T̄

has to be enforced that the pseudo stress vector yields the same flow direction as its physical counterpart, i.e.,

∂T̄ (i) g (i) |T̄˜ (i) = ∂T̄ (i) g (i) |T̄ (i) . In what follows, only flow rules based on a plastic potential in the form of a

positively homogeneous function of degree one will be considered. In this case, the aforementioned compatibility

between the pseudo stresses and the physical stresses can be checked by analyzing condition (37). Interestingly,

the advocated novel parameterization of the flow rule is formally identical to that proposed in [45, 46] for standard

(continuous deformation) plasticity theory.

Inserting the novel parameterization (48) into the stress power (40) defines the alternative minimization problem

˜ (ns ) , λ(ns ) ).

˜ (1) , λ(1) , . . . , T̄

˜ (ns ) , λ(ns ) ) = arg

˜ (1) , λ(1) , . . . , , T̄

(49)

inf

E(ϕ̇, T̄

(ϕ̇, T̄

˜ (ns ) ,λ(ns )

˜ (1) ,λ(1) ,...,T̄

T̄

While for associative evolution equations both frameworks of energy minimization (compare Eq. (49) to Eq. (41))

lead, in principle, to identical results, only the novel variational problem (49) can be applied to non-associative

evolution equations. The reason is that the flow rule and the dissipation can be chosen independently. As a

consequence, Eq. (49) can be considered as an enhanced or extended principle of maximum dissipation. More

precisely, the stress power depending on a certain dissipation is minimized by simultaneously enforcing a suitable

flow rule. However, it bears emphasis that also for associative models minimization principle (49) shows an

important advantage: All highly nonlinear constraints related to the flow rule are already naturally included and

thus enforced.

Since variational principle (49) is non-standard and furthermore, it depends on the parameter c, consistency

will be shown next, i.e., it is proved that the minimizers of Eq. (49) are equivalent to the underlying evolution

equations and the yield function. According to Section 2, the kinematics associated with cracks and that related to

shear bands are slightly different. For this reason, consistency is proved for both cases separately.

Slip bands – mode-II and mode-III failure The functional to be minimized is the stress power. Thus, the strain

rate is required. By utilizing Eq. (12)2 , it is computed as

n1

ns

i=1

i=1

X

X ˙

(i)

˙

F̂ · J̇ ⊗ GRADϕ(i) .

F̂ · J (i) ⊗ GRADϕ(i) −

F̄˙ = F̂ −

(50)

12

J. Mosler, L. Stanković and R. Radulović

Hence, for a variation of Eq. (49) with respect to the plastic multiplier and the pseudo stresses, the continuous part

of the displacement field can be considered as constant, i.e.,

û = const

⇒

˙

F̂ = 0

⇒

F̄˙ = −

ns

X

i=1

F̂ · J̇

(i)

⊗ GRADϕ(i) .

(51)

T

By utilizing the Mandel stresses Σ = F̂ · ∂F̄ Ψreg and assuming slip planes parallel to the facets of the finite

elements (GRADϕ(i) ||N (i) ) (see Remark 7), the stress power reads

!

ns

ns

ns

X

X

X

(i)

(i)

(i) (i) (i)

(i)

(i)

(i)

.

(52)

D

q λ δs +

(λ ∂T̄ (i) g ⊗ N ||GRADϕ ||) + c

E = −Σ :

{z

}

|

{z

} |

i=1

i=1

i=1

(i)

GRADϕ(i)

J˙

In what follows, constitutive models falling into the range of the general framework as presented in Paragraph 3.2.2

will be utilized. Thus, the stress power (52) can be re-written as

ns

X

ns

X

ns

X

(i)

λ(i) (q0eq − (T̄Neq )(i) ) δs(i) .

|

{z

}

i=1

i=1

= D(i) , see Eq. (36)

(53)

Based on Eq. (53) consistency of the novel minimization principle can be analyzed. First, the stationarity condition

of E with respect to plastic multiplier λ(i) is computed. It results in

n

h

io

(i)

(i)

eq(i)

δλ E = −T̄S

||GRADϕ(i) || + δs(i) c q (i) + q0eq − (T̄Neq )(i)

δλ(i) = 0.

(54)

E = −Σ :

(λ(i) ∂T̄ (i) g (i) ⊗ N (i) ||GRADϕ(i) ||) + c

{z

}

|

{z

} |

i=1

(i)

GRADϕ(i)

J˙

q (i) λ(i) δs(i) +

Unfortunately, Eq. (54) cannot be interpreted easily, since it contains, in addition to a regular part, a singular

distribution. For that purpose, Eq. (54) is integrated over the domain of a finite element e. This leads to

Z

io

h

n

(i)

eq(i)

eq (i)

eq (i)

(i)

δλ(i) = 0.

(55)

c

q

+

q

−

(

T̄

)

||GRADϕ(i) || V e + A(i)

δλ E dV = −T̄S

s

0

N

Ωe

For the sake of simplicity, constant stresses and constant internal variables have been assumed. However, the

more general case follows identical lines and it is included in what follows. As shown in the appendix, for threedimensional tetrahedron elements based on a linear approximation of the undeformed configuration and a linear

ramp function ϕ defined by the shape functions of the corner nodes, the identity

||GRADϕ(i) || V e

(i)

As

= c(i)

geom

(56)

(i)

is fulfilled. The parameter cgeom is related to the relative position of the slip bands within the respective finite

element and does not depend on the size of the element. For instance, if the slip bands are chosen to be identical

(i)

to the facets of the finite elements, cgeom = 2. Hence, combining Eq. (55) with Eq. (56) leads to the natural choice

c = cgeom and thus, the integrated stationarity condition of E with respect to the plastic multiplier of slip band i is

finally obtained as

Z

(i)

Ωe

(i)

δλ E dV = −A(i)

δλ(i) = 0.

s cgeom φ

(57)

Consequently, stability of E with respect to the plastic multiplier δλ(i) is equivalent to fulfilling the yield function

at the discontinuity in a weak form (or continuity of the traction vector), i.e.,

Z

(i)

δλ E dV ≥ 0 ⇔ φ(i) ≤ 0.

(58)

Ωe

The derivation of the stationarity condition reveals the physical interpretation of the parameter c: While in classical

Embedded Strong Discontinuity Approaches (ESDA) the size of the slip band does not influence the results, cf.

[11, 50, 50, 51], this is not the case within the novel variational formulation. Only if c = cgeom is chosen, both

methods give identical results. Clearly, from a physical point of view, the area of the discontinuity should affect

the softening behavior. In this respect, the novel variational formulation is more realistic. However, in the present

A variationally consistent embedded strong discontinuity approach

13

paper, focus is on a variational re-formulation of the original ESDA. The influence of the slip band size on the

solution is beyond the scope of this work and will be analyzed in a forthcoming paper.

Fully analogously to the variation of the integrated stress power with respect to the plastic multiplier, station˜ (i) leads finally to

arity with respect to the pseudo stresses T̄

(i)

˜ (i) = 0

δT̄˜ (i) E = −λ(i) ||GRADϕ(i) || T̄ · ∂T̄2 (i) g (i) ˜ (i) · δ T̄

T̄

(59)

(i)

⇔ T̄ · ∂T̄2 (i) g (i) ˜ (i) = 0.

T̄

Hence, the compatibility condition between the pseudo stresses and their physical counterparts is fulfilled as well

(compare to Eq. (37)). As a result, the advocated novel minimization principle is indeed consistent.

The fundamentals of the advocated novel variational constitutive update are completed by the stress response.

By decomposing the minimization problem (49), into a local part inf E|û=const , the reduced potential

Ered = inf

˜ (1) ,λ(1) ,...,T̄

˜ (ns ) ,λ(ns )

T̄

˜ (1) , λ(1) , . . . , T̄

˜ (ns ) , λ(ns ) ).

E(ϕ̇, T̄

(60)

is defined from which the stresses can be derived, i.e.,

P = ∂F̄˙ Ered .

(61)

The general case including mixed-mode cracking Applying the same procedure as before to the general case

(J · N 6= 0) shows that variationally consistency cannot be guaranteed anymore. This is closely related to the

simplified kinematics (12) holding only for J · N = 0 and to the Petrov-Galerkin-type approximation of the

underlying finite element formulation (see Remark 7). However, this effect is only relevant for large deformations.

For this reason, focus is now on a geometrically linearized setting. In this case, the strain tensor reads

ε̄ = [GRADû]sym −

n1 X

[ u]]

(i)

i=1

⊗ GRADϕ(i)

sym

.

(62)

Denoting the stress tensor of the geometrically linearized theory as σ and the respective traction vector as T , the

stress power is computed as (compare to Eq. (52))

!

ns

ns

ns

X

X

X

(i)

(i)

(i) (i) (i)

(i)

(i) sym

(i)

D

q λ δs +

+c

(λ ∂T (i) g ⊗ N ||GRADϕ ||)

E = −σ :

i=1

i=1

i=1

(63)

ns n

io

h

X

(i)

eq(i)

λ(i) = 0.

−TS

||GRADϕ(i) || + δs(i) c q (i) + q0eq − (TNeq )(i)

=

i=1

Accordingly, the geometrically linearized framework leads to the same variational principle (compare Eq. (63) to

Eq. (54)). However and in sharp contrast to the finite strain kinematics, the strain field (62) holds now for any

material failure type. Consequently, mode-II and mode-III but also mode-I or mixed-mode material failure can be

accounted for. The remaining steps necessary for proving variational consistency are omitted here. They are fully

identical to those already presented in the previous paragraph.

Remark 4 The proposed variational constitutive update requires four degrees of freedom per discontinuity. Three

˜ (i) = 3), while an additional unknown describes

unknowns are necessary for defining the flow direction (dim T̄

(i)

the amplitude of inelastic deformations (dim λ = 1). Thus, from a computational point of view, it is more

efficient to parameterize the plastic deformations directly reducing the number of unknowns by one. The respective

modifications are straightforward and have already been explained for a von Mises prototype model. Furthermore,

(i)

in case of slip bands, J (i) · N (i) = 0 and consequently, J̇ · N (i) = 0. As a result, enforcing this constraint in

advance, leads to a further reduction of the number of unknowns. More precisely, the modeling of each slip band

requires then a parameterization depending on only two degrees of freedom, i.e.,

(i)

(i)

(i)

(i)

J̇ = λM1 M 1 + λM2 M 2 ,

(i)

(i)

(i)

Ṁ 1 = Ṁ 2 = 0 = 1 − ||M 1 || = 1 − ||M 2 ||,

(M 1 × M 2 ) · N = 1 (64)

(i)

Again, the unknowns λM1 and λM2 can be computed conveniently by minimizing the associated stress power.

Remark 5 A positively homogeneous plastic potential of degree one is considered within the present paper. It

bears emphasis that this property is crucial for employing the parameterization (48) in terms of pseudo stresses.

As stated in [46], the proposed decomposition of the flow rule into an amplitude and into a direction yields unique

results only in this case.

14

J. Mosler, L. Stanković and R. Radulović

Remark 6 By utilizing the chain rule, the identity

∂T̄ (i) g (i) ⊗ GRADϕ(i) = ∂Σ g̃ (i) ||GRADϕ(i) ||

(65)

can be shown in a straightforward manner. Here, g̃ (i) is the plastic potential, but now in terms of the Mandel

stresses, i.e.,

(i)

g̃ (i) (Σ) = (g (i) ◦ T̄ )(Σ).

(66)

Hence, by employing again the concept of pseudo stresses, the modified flow rule (65) can be parameterized as

o

n

(67)

∂T̄ (i) g (i) ⊗ GRADϕ(i) ∈ ∂Σ g̃ (i) ||GRADϕ(i) || Σ̃ ∈ R3×3 .

Σ̃

Since this parameterization can be applied to any of the active yield surfaces, the influence of all strong discontinuities on the deformation gradient can be described by the plastic multipliers and the pseudo stresses, i.e.,

ns

X

i

J̇

(i)

⊗ GRADϕ(i) =

ns

X

i

with

λ(i) ∂Σ φ(i) ǫp :=

ns

X

i=1

Σ̃

||GRADϕ(i) || = ǫ̇p (λ(1) , . . . , λ(ns ) , Σ̃)

J (i) ⊗ GRADϕ(i) .

(68)

(69)

This new parameterization leads to ns + dim Σ̃ unknowns. Consequently, in case of an elastically isotropic bulk

material ns + 6 degrees of freedom have to be computed. If pseudo stress vectors are utilized, ns + 3 ns variables

are required. Consequently, a pseudo stress tensor is computationally more efficient than its vector counterpart, if

more than one discontinuity is active.

Remark 7 The derivation of a variationally consistent strong discontinuity approach relies strongly on two terms.

First, the constitutive model has to be driven by a certain variational principle. In the present paper, this principle

is an extended principle of maximum dissipation in which non-associative evolution equations are enforced by

using a parameterization by means of pseudo stresses. Second, the finite element formulation has to conserve this

material symmetry (variational consistency). While this is automatically guaranteed for Bubnov-Galerkin-type

approaches such as the extended finite element method or classical interface elements, the considered embedded

strong discontinuity approach (ESDA) is based on a Petrov-Galerkin discretization. However, the ESDA is only

symmetric provided the cracks or shear bands are parallel to the facets or the edges of the underlying finite

element discretization. Thus, the assumption of cracks or shear bands being parallel to the elements’ facets and

edges would not be required in case of the extended finite element method. In summary, the proposed variational

constitutive update could also be incorporated into a broad variety of other finite element formulations based on

strong discontinuities including the extended finite element method or classical interface elements. If the respective

formulation was intrinsically variationally consistent (Bubnov-Galerkin-type), the resulting numerical approach

would be automatically symmetric, regardless of the orientation of the discontinuities and the failure mode. For

instance, the finite strain counterpart of the proposed mixed-mode model would be variationally consistent in this

case for any discontinuity. Details about this consistency for other finite element formulations are beyond the scope

of the present paper, but will be discussed in a forthcoming paper.

4 NUMERICAL IMPLEMENTATION

This section is concerned with the numerical implementation of the embedded strong discontinuity approach presented in the previous sections. While in Subsection 4.1 an algorithmic formulation based on a modified returnmapping scheme is briefly discussed, a novel variational constitutive is elaborated in Subsection 4.2. Since the

constitutive framework, including the variational principle, associated with slip bands and that related to cracks are

formally identical (cf. Subsection 3.2.3), the numerical implementations will only be discussed in detail for one of

such material failures. More precisely, focus is on slip bands.

4.1 Return-mapping algorithm

The numerical implementations for finite elements based the embedded strong discontinuity approach can be

classified into two groups, cf. [32]. The majority of the models relies strongly on the underlying Enhanced

Assumed Strain (EAS) concept, cf. [28]. More precisely, the degrees of freedom associated with the continuous

deformation û and those corresponding to the displacement discontinuities are computed simultaneously. For that

A variationally consistent embedded strong discontinuity approach

15

purpose, a static condensation technique is usually applied, see [11, 51]. Alternatively, some authors advocated a

numerical implementation based on a modified return-mapping scheme, cf. [39, 40, 57, 73]. By extensively using

the analogy between the strong discontinuity kinematics and that related to multiplicative plasticity theory, it can

be shown that the algorithms originally derived for standard (continuous) plasticity theory can also be applied to

the discontinuous case. This is precisely the framework which will be followed in the present paper.

According to Subsection 2.2, two different approximations exist in case of multiple strong discontinuities,

compare Eq. (15) to Eq. (16). Both have been implemented. However, since their algorithmic formulations are

similar, only one of those will be described in detail. Due to the efficiency of approximation (16), it is chosen as

prototype.

4.1.1 Elastic predictor

Assuming a purely elastic loading step, the material displacement jumps J (i) remain constant. It bears emphasis

that this is not true for their spatial counterparts, i.e.,

J̇

With assumption J̇

(i)

tr

F̄ n+1

(i)

=0

6⇒

[ u̇]]

(i)

=

i

d h

F̂ · J (i) = 0.

dt

(70)

= 0, the (elastic) trial deformation gradient at time tn+1 can be computed according to

= F̂ n+1 − F̂ n+1 ·

ns

X

β=1

(β)

J (β)

,

n ⊗ GRAD ϕ

F̂ n+1 = 1 + GRAD ûn+1

(71)

tr

which, in turn, defines the right Cauchy-Green trial tensor C̄ n+1 , the second Piola-Kirchhoff trial stresses S tr

n+1

and finally, the trial stress vector

(β) tr

tr

(β)

T̄ n+1 = C̄ n+1 · S tr

n+1 · N

(72)

at internal surface β. Subsequently, the discrete loading condition

(β) tr

(β) tr

φ(β) tr := φ(β) (T̄ n+1 , q n+1 ) > 0 with

(β) tr

q n+1 = q (β)

n .

(73)

can be checked. Clearly, if φ(β) tr ≤ 0 for all beta, the trial step represents already the physical solution. If one of

the yield functions is, however, active (φ(β) tr > 0), a plastic corrector step is required. In the next paragraph, such

a corrector step is described in detail. For the sake of simplicity, it is assumed that the set of active yield surfaces

Jact is known. Clearly, this is usually not the case. More precisely, the computation of this set is highly challenging

itself and thus, a subject of its own, cf. [74]. Some comments concerning the employed active set search can be

found in Paragraph 4.1.3.

4.1.2 Plastic corrector

(β)

(β)

For active yield surfaces, the assumption J̇

= 0 was obviously not correct. Hence, J n+1 6= J (β)

n . In line with

the classical return-mapping scheme for continuous deformations, cf. [75, 76], a backward Euler integration is

applied for approximating the flow rule and the evolution equations. More precisely,

(i)

(i)

J n+1 = J (i)

∂T̄ (i) g (i) n + ∆λ

n+1

(74)

(i)

(i)

(i) αn+1 = α(i)

+

∆λ

∂

g

.

q (i)

n

n+1

For solving the set of nonlinear equations (74), together with φ(i) = 0, ∀i ∈ Jact , Newton’s method is applied.

However, a direct implementation of those equations would lead to a singular Hessian, if several discontinuities

were active. This problem is fully analogous to that of crystal plasticity theory, cf. [74]. For that reason, the plastic

strain-type tensor

ns

X

p

ǫ :=

J (β) ⊗ GRADϕ(β)

(75)

β=1

is introduced and Eq. (74)1 is replaced by

ǫp n+1 = ǫp n +

X

β∈Jact

∆λ(β) ∂ T̄(β) g (β) |n+1 ⊗ GRAD ϕ(β) .

(76)

16

J. Mosler, L. Stanković and R. Radulović

Finally, the residuum R

is defined with

p

R ǫ = −ǫp n+1 + ǫp n +

and

R :=

X

∆λ(β) ∂ T̄(β) g (β) |n+1 ⊗ GRAD ϕ(β)

β∈Jact

p

Rǫ

Rα

,

(77)

(1)

(1)

∂ q(1) g (1) |n+1

−αn+1 + α(1)

n + ∆λ

R α :=

,

...

nact

(nact )

(nact )

(nact )

−αn+1 + αn

+ ∆λ

∂ q(nact ) φ

|n+1

nact := dim Jact .

(78)

(79)

and the set of equations

R=0

∧

(β)

φn+1 = 0 , β = 1, . . . , nact .

(80)

is solved by means of Newton’s method. Within this scheme, the variables (ǫp , q (i) , ∆λ(i) ) have been chosen as

the independent unknowns. Although the linearizations necessary for an asymptotically quadratic convergence are

quite lengthy, they can be computed in a standard fashion. For a single discontinuity they can be found in [39],

while the case of multiple discontinuities is described in [59].

4.1.3 Numerical aspects

Choice of the unknown variables within the return-mapping scheme According to the previous paragraph,

the variables (ǫp , q(i) , ∆λ(i) ) have been chosen as independent unknowns within the return-mapping scheme.

(i)

As already mentioned, the replacement of the stress vectors T̄ by ǫp is motivated by an analogy to crystal

(i)

plasticity theory: If T̄ had been chosen, the resulting Hessian would have been singular in case of multiple active

discontinuities. However, the choice of ǫp as unknown variable is not the only choice. The Mandel stresses Σ could

have been utilized as well. As a matter of fact, the original implementation was based on this parameterization.

However, convergence problems due to the linearization of Σ had been observed. Such drawbacks are not present

within the current implementation.

Enforcing a positive plastic multiplier In several numerical examples, the converged return-mapping state

showed a negative plastic multiplier. Even by employing the standard active set search strategy as briefly summarized in the following paragraph, such problems could not be eliminated. For this reason, ∆λ ≥ 0 was explicitly

enforced by setting ∆λ = a2 .

Active set search The set of potentially active singular surfaces within the return-mapping scheme is not necessarily constant, i.e., Jn+1 := {i|φ(i) > 0} 6= const. This is a well known problem frequently reported in crystal

plasticity theory, cf. [74]. Usually, two different strategies are applied. For solving this problem, either the set

Jn+1 := {i|φ(i) > 0} is updated during the iterations, or it is modified at a converged step and an additional

Newton iteration is performed subsequently, cf. [75, 76]. Without going to much into detail, it is noted that both

schemes are purely heuristic. However, the latter guarantees, at least, a quadratic convergence. Consequently, this

approach is chosen. In the next section, a novel variational constitutive update will be presented. This method

naturally solves the aforementioned problem.

4.2 Variational constitutive updates

In contrast to the return-mapping scheme presented in the previous section, the novel variational constitutive update discussed here is directly based on the underlying extended principle of maximum dissipation, see Eq. (49)

and Eq. (60). Conceptually, the overriding idea is astonishingly simple: The continuous variational principle is

approximated by a consistent time integration yielding a consistent numerical implementation.

According to Paragraph 3.2.3, the aforementioned extended principle of maximum dissipation is the minimization of the stress power. Hence, application of this principle within a numerical formulation requires a proper time

discretization. In line with the return-mapping scheme presented in the previous subsection, a backward-Euler

integration is applied here. More precisely,

(i)

(i)

J n+1 = J n+1 + ∆λ(i) ∂T̄ (i) g (i) ˜ (i)

T̄ n+1

(81)

(i)

(i)

(i)

(i) αn+1 = αn + ∆λ

∂q (i) g .

n+1

A variationally consistent embedded strong discontinuity approach

17

Evidently, the only difference between Eq. (81) and Eq. (74) is the parameterization of the flow direction by means

˜ (i) . As pointed out in Remark 6, Eq. (81) can be replaced by an equivalent description

of pseudo stress vectors T̄

1

in terms of a pseudo stress tensor Σ̃, i.e.,

X

∆λ(i) ∂Σ̃ g̃ (i) ||GRADϕ(i) ||

(82)

ǫp n+1 = ǫp n +

i∈Jact

Σ̃n+1

with ǫp as defined in Eq. (69). According to Remark 6, this parameterization is more efficient than that depending

on pseudo stress vectors, if more than one discontinuity is active within the considered finite element. For that

reason, parameterization (82) is chosen in what follows. However, efficiency is not the only advantage of this

approach. More precisely, it will be shown that in this case, the resulting variational constitutive update is almost

identical to that previously derived for standard (stress-strain-based) material models, cf. [45, 46].

Based on time integrations (81)2 and (82) the integrated stress power can be computed. For that purpose,

Eq. (81)2 and Eq. (82) are inserted into the Helmholtz energy Ψ yielding

Ψ(tn+1 ) =: Ψn+1 = Ψreg |n+1 + c

ns

X

i=1

(i)

δs(i) Ψsing |n+1 .

(83)

The second term necessary for computing the integrated stress power is the dissipation. With Eq. (36), a backwardEuler integration yields

tZ

n+1

ns

X

(i)

.

(84)

∆λ(i) δs(i) q0eq − (T̄Neq)(i) D dt =

n+1

i=1

tn

Finally, by combining Eqs. (81)–(84), the integrated stress power

Iinc :=

tZ

n+1

E dt = Ψn+1 − Ψn + c

tn

tZ

n+1

D dt

(85)

tn

is completely defined. Since the time discretization (81) is consistent, Eq. (85) is a consistent first-order approximation of the underlying functional (49). Accordingly, the novel variational constitutive update reads

(∆λ(1) , . . . , ∆λ(ns ) , Σ̃) = arg inf Iinc (∆λ(1) , . . . , ∆λ(ns ) , Σ̃).

(86)

Consistency of the novel variational constitutive update (86) is not obvious. Consequently, it will be proved

here. For that purpose, the stationarity conditions are analyzed. After some relatively straightforward computations, the gradients of the energy Iinc are obtained as

eq (i) T

∂Iinc

eq (i)

eq (i)

(i) ∂(T̄ N )

(i)

(i)

(i)

e

− ∆λ

+ c δs

q0

− (T̄ N )

= − F̂ · ∂F̄ Ψ : ∂T̄ (i) g ⊗ GRADϕ

∂∆λ(i)

∂∆λ(i)

eq (i) eq (i)

eq (i)

eq (i)

(i) ∂(T̄ N )

(i)

(i)

− ∆λ

q0

− (T̄ N )

=

−(T̄ S ) ||GRADϕ ||

+ c δs

∂∆λ(i)

(87)

and

ns eq

X

T

∂(T̄ N )(i)

∂Iinc

2 (i)

g̃ |Σ̃ ||GRADϕ(i) || − c ∆λ(i) δs(i)

.

(88)

F̂ · ∂F̄ Ψe : ∂Σ

=−

∂ Σ̃

∂ Σ̃

i=1

Alternatively, a parameterization in terms of pseudo stress vectors leads to

∂Iinc

˜ (i)

∂ T̄

=

=

−

i

h T

F̂ · ∂F̄ Ψe · GRADϕ(i) · ∂T̄2 g (i) |T̄˜ (i)

−T̄

(i)

eq

−

c ∆λ(i) δs(i)

∂(T̄ N )(i)

˜ (i)

∂ T̄

eq

· ∂T̄2 g (i) |T̄˜ (i) ||GRADϕ(i) ||

− c ∆λ(i) δs(i)

(89)

∂(T̄ N )(i)

.

˜ (i)

∂ T̄

Fully analogously to Paragraph 3.2.3, the singular Dirac-Delta distributions are eliminated by integrating the equations over the respective finite element. For example, for constant strain tetrahedron elements, Eq. (87) is re-written

as

Z

∂Iinc

eq (i)

eq (i)

eq

e

(i)

(i)

dV

=

−V

(

T̄

)

||GRADϕ

||

+

c

A

q

−

(

T̄

)

− rλ (∆λ(i) ),

(90)

S

s

N

0

∂∆λ(i)

Ωe

18

J. Mosler, L. Stanković and R. Radulović

while Eq. (89) yields

Z

Ωe

∂Iinc

(i)

dV = −T̄ · ∂T̄2 g (i) |T̄˜ (i) ||GRADϕ(i) || V e − rT (∆λ(i) ).

˜ (i)

∂ T̄

(91)

Here, rλ and r T are two residuals depending on ∆λ, i.e.,

eq

rλ (∆λ(i) )

(i)

= c A(i)

s ∆λ

∂(T̄ N )(i)

∂∆λ(i)

eq

(i)

rT (∆λ )

= c

A(i)

s

(i)

∆λ

∂(T̄ N )(i)

.

˜ (i)

∂ T̄

(92)

Hence, in the limiting case ∆t → 0, these residua converge to zero and as a result, stationarity conditions (90) and

(91) simplify to

Z

∂Iinc dV = 0 ⇔ φ(i) = 0