AN-1146 APPLICATION NOTE ADIS16334

advertisement

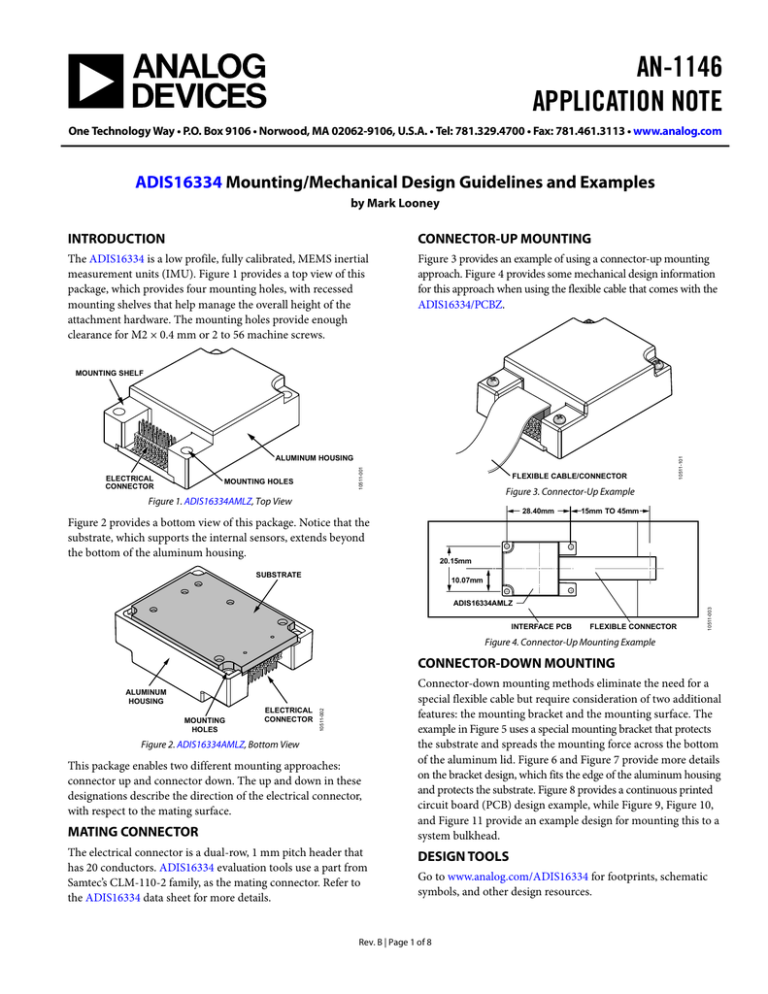

AN-1146 APPLICATION NOTE One Technology Way • P.O. Box 9106 • Norwood, MA 02062-9106, U.S.A. • Tel: 781.329.4700 • Fax: 781.461.3113 • www.analog.com ADIS16334 Mounting/Mechanical Design Guidelines and Examples by Mark Looney INTRODUCTION CONNECTOR-UP MOUNTING The ADIS16334 is a low profile, fully calibrated, MEMS inertial measurement units (IMU). Figure 1 provides a top view of this package, which provides four mounting holes, with recessed mounting shelves that help manage the overall height of the attachment hardware. The mounting holes provide enough clearance for M2 × 0.4 mm or 2 to 56 machine screws. Figure 3 provides an example of using a connector-up mounting approach. Figure 4 provides some mechanical design information for this approach when using the flexible cable that comes with the ADIS16334/PCBZ. MOUNTING HOLES FLEXIBLE CABLE/CONNECTOR Figure 3. Connector-Up Example Figure 1. ADIS16334AMLZ, Top View 28.40mm Figure 2 provides a bottom view of this package. Notice that the substrate, which supports the internal sensors, extends beyond the bottom of the aluminum housing. 15mm TO 45mm 20.15mm SUBSTRATE 10.07mm ADIS16334AMLZ INTERFACE PCB FLEXIBLE CONNECTOR 10511-003 ELECTRICAL CONNECTOR 10511-001 ALUMINUM HOUSING 10511-101 MOUNTING SHELF Figure 4. Connector-Up Mounting Example CONNECTOR-DOWN MOUNTING MOUNTING HOLES ELECTRICAL CONNECTOR 10511-002 ALUMINUM HOUSING Figure 2. ADIS16334AMLZ, Bottom View This package enables two different mounting approaches: connector up and connector down. The up and down in these designations describe the direction of the electrical connector, with respect to the mating surface. MATING CONNECTOR The electrical connector is a dual-row, 1 mm pitch header that has 20 conductors. ADIS16334 evaluation tools use a part from Samtec’s CLM-110-2 family, as the mating connector. Refer to the ADIS16334 data sheet for more details. Connector-down mounting methods eliminate the need for a special flexible cable but require consideration of two additional features: the mounting bracket and the mounting surface. The example in Figure 5 uses a special mounting bracket that protects the substrate and spreads the mounting force across the bottom of the aluminum lid. Figure 6 and Figure 7 provide more details on the bracket design, which fits the edge of the aluminum housing and protects the substrate. Figure 8 provides a continuous printed circuit board (PCB) design example, while Figure 9, Figure 10, and Figure 11 provide an example design for mounting this to a system bulkhead. DESIGN TOOLS Go to www.analog.com/ADIS16334 for footprints, schematic symbols, and other design resources. Rev. B | Page 1 of 8 AN-1146 Application Note TABLE OF CONTENTS Introduction ...................................................................................... 1 Design Tools .......................................................................................1 Mating Connector ............................................................................ 1 Revision History ................................................................................2 Connector-Up Mounting................................................................. 1 Connector-Down Mounting ........................................................... 1 REVISION HISTORY 9/12—Rev. A to Rev. B Changes to Figure 8 .......................................................................... 4 6/12—Rev. 0 to Rev. A Added Mating Connector Section ................................................. 1 4/12—Revision 0: Initial Version Rev. B | Page 2 of 8 Application Note AN-1146 M2 × 0.4mm MACHINE SCREWS ADIS1633x/BRACKET (MOUNTING BRACKET) ADIS16334BMLZ CUT-OUT FOR TOP OF ADIS16334 10511-004 MATING CONNECTOR/PCB Figure 5. Connector-Down Mounting Example SHELF DIMENSIONS SUPPORT DIRECT CONTACT WITH THE BOTTOM OF THE ADIS16334BMLZ HOUSING 10511-005 CUT-OUT AREA PREVENTS CONTACT WITH ADIS16334BMLZ SUBSTRATE Figure 6. ADIS1633x/BRACKET, Physical Features Rev. B | Page 3 of 8 AN-1146 Application Note 26.99 3.18 12.33 2.70 26.99 23.57 3.42 3.42 31.82 10511-006 35.54 3.72 23.27 Figure 7. ADIS1633x/BRACKET, Design Details Ø 0.64 × 2 Ø 2.40 × 4 22.20 16.43 2.65 1.60 1.60 × 2 2.35 25.78 29.58 10511-007 4.35 2.35 8.43 24.85 23.25 22.50 20.50 Ø 2.75 × 2 30.75 Figure 8. Connector-Down, Continuous PCB Mechanical Design Rev. B | Page 4 of 8 Application Note AN-1146 M2 × 0.4mm MACHINE SCREWS ADIS1633x/BRACKET (MOUNTING BRACKET) ADIS16334BMLZ MATING CONNECTOR/PCB MACHINED FOR TOP OF ADIS16334 10511-008 SYSTEM BULKHEAD Figure 9. Connector-Down, Bulkhead Mounting Example Rev. B | Page 5 of 8 Application Note 2.90 15 AN-1146 22.20 5.28 1.50 2.35 3.763 2.65 10511-009 25.78 30.75 Figure 10. Bulkhead Mechanical Design Example 13.20 10.60 1.57 ± 10% 2.60 3.64 9.50 Ø 0.64 × 2 10511-010 1.50 2.35 3.75 19.28 24.85 23.35 22.50 21.13 Ø2×4 Figure 11. PCB Interface Design Example Rev. B | Page 6 of 8 Application Note AN-1146 NOTES Rev. B | Page 7 of 8 AN-1146 Application Note NOTES ©2012 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. AN10511-0-9/12(B) Rev. B | Page 8 of 8