Surge Testing of Digital Isolators

advertisement

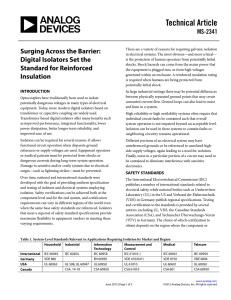

Surge Testing of Digital Isolators Many applications require isolation of hazardous voltages in order to meet international safety standards. To ensure the safety of equipment and operators, these standards often require that isolating components, such as digital isolators or optocouplers, survive high voltage surges in excess of 10 kV (peak). The ability to test the surge capability of an isolator is, therefore, an essential part of developing safe and reliable components. The International Electrotechnical Commission (IEC) and Verband der Elektrotechnik (VDE) are two organizations that publish standards governing system and component level application of isolation technologies for medical, industrial, consumer, and automotive systems, among others. To ensure the safety of people and equipment in the presence of a high voltage surge, these standards specify different surge ratings depending on the class, or level, of isolation required for a given application. discharge the circuit after each pulse has been applied. An oscilloscope with a 1000:1 high voltage probe is used to monitor the pulses. The gun is set at the lowest voltage called for in the test plan, and the oscilloscope is set for single triggering. Ten pulses are applied at that voltage level, and each pulse is monitored with the oscilloscope. A breach in the isolation barrier is manifested by a precipitous decrease in the pulse amplitude (decaying to 50% in much less than 50 μs). If the part survives ten pulses, then the gun voltage is increased, and ten more pulses are applied. This continues until the barrier fails or the maximum test voltage has been reached. ISOLATION BARRIER There are three common classes of isolation: functional, basic, and reinforced. Functional isolation has few safety requirements because it is used typically only where separation of ground references is required to allow a circuit to operate properly. Safety, and, therefore, surge performance, is not a primary consideration for functional isolation. Safety is, however, the key consideration for basic and reinforced isolation, so surge levels are critical in defining the quality of isolation. Basic isolation provides protection from shock for users of the end equipment, and reinforced isolation is a single isolation system that provides protection equal to two redundant single, or basic, isolation systems. Medical and industrial applications commonly require reinforced insulation to protect patients or end users from potentially lethal shocks. VDE’s standard for reinforced isolation for digital isolators, VDE 0884-10, specifies a minimum surge voltage (VIOSM) rating of 10 kV, in addition to working voltage (VIORM) and withstand voltage (VISO) requirements. The surge voltage rating of a digital isolator defines survivability after a repetitive series of short duration high voltage pulses. Figure 1 illustrates the timing characteristics of a surge waveform according to IEC 61000-4-5. GND1 VDD1 VDD2 I/O1 I/O2 GND1 GND2 GND2 100k𝛀 1000k𝛀 V 1000pF Figure 2. Surge test setup. The ability to pass this test is primarily determined by the insulation thickness (also known as distance through insulation, or DTI) and the quality of the insulating material. The applied electric field tends to concentrate at defect points within the insulator, so lower defect densities generally lead to higher breakdown ratings. Thicker materials are more resistant to breakdown since the field strength is inversely proportional to the distance between the conductors on either side of the insulation. Figure 1. Surge voltage waveform. Optocouplers commonly pass 10 kV surge testing because the insulation is very thick (typically 400 µm), which reduces the impact of insulation quality on the breakdown characteristics. Simply put, the insulation is so thick that a high quality material is not required to pass the 10 kV test. Transformerbased isolators use a high quality 20 µm to 32 μm polyimide layer deposited in a clean room environment. Since this material has a much lower defect level than the injection molded epoxies used in optocouplers, a much thinner layer can still meet the 10 kV requirement. Capacitive isolators also use a high quality insulating layer, in this case silicon dioxide (SiO2) deposited during wafer fabrication. Silicon dioxide has a high dielectric strength but typically can’t be deposited in very thick layers without creating mechanical stress within the film. Thicker SiO2 also reduces the capacitance, which, in turn, reduces the coupling efficiency across the barrier. For this reason, capacitive isolators typically will not pass the 10 kV surge test and, therefore, cannot currently be certified by VDE as reinforced insulation. The test is carried out by placing the device on a test board and shorting all pins on both sides of the isolation barrier (see Figure 2). A high voltage pulse generator is connected to one side of the isolation barrier through a 1000 Ω/1000 pF network. The generator return is connected to the other side of the barrier. A 100 kΩ, 2.5 W resistor is placed across the barrier to Protection from a 10 kV surge is required in applications requiring reinforced isolation, where people and equipment are being protected. Surge testing is a critical step in establishing the safety level of isolating components in such applications. Analog Devices offers a large portfolio of iCoupler® and isoPower® products that meet this requirement. VOLTAGE VIOSM 90% VIOSM 50% VIOSM 10% VIOSM 1.2𝛍s 50𝛍s TIME www.analog.com/iCoupler Analog Devices, Inc. Worldwide Headquarters Analog Devices, Inc. One Technology Way P.O. Box 9106 Norwood, MA 02062-9106 U.S.A. Tel: 781.329.4700 (800.262.5643, U.S.A. only) Fax: 781.461.3113 Analog Devices, Inc. Europe Headquarters Analog Devices, Inc. Wilhelm-Wagenfeld-Str. 6 80807 Munich Germany Tel: 49.89.76903.0 Fax: 49.89.76903.157 Analog Devices, Inc. Japan Headquarters Analog Devices, KK New Pier Takeshiba South Tower Building 1-16-1 Kaigan, Minato-ku, Tokyo, 105-6891 Japan Tel: 813.5402.8200 Fax: 813.5402.1064 Share this on: ©2012 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners. T10669-0-4/12 Follow ADI: www.analog.com/iCoupler twitter.com/adi_news Analog Devices, Inc. Southeast Asia Headquarters Analog Devices 22/F One Corporate Avenue 222 Hu Bin Road Shanghai, 200021 China Tel: 86.21.2320.8000 Fax: 86.21.2320.8222