Document 11612142

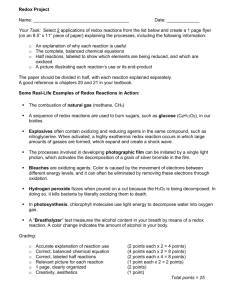

advertisement