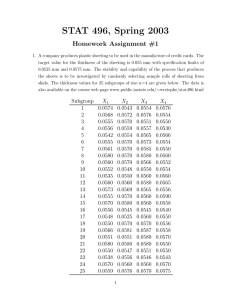

STAT 496, Spring 2004 Homework Assignment #1

advertisement

STAT 496, Spring 2004 Homework Assignment #1 1. A company produces plastic sheeting to be used in the manufacture of credit cards. The target value for the thickness of the sheeting is 0.055 mm with specification limits of 0.0525 mm and 0.0575 mm. The stability and capability of the process that produces the sheets is to be investigated by randomly selecting sample rolls of sheeting from skids. The thickness values for 25 subgroups of size n=4 are given below. The data is also available on the course web page www.public.iastate.edu/∼wrstephe/stat496.html Subgroup 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 X1 0.0574 0.0568 0.0555 0.0556 0.0542 0.0555 0.0561 0.0580 0.0560 0.0552 0.0535 0.0560 0.0573 0.0555 0.0570 0.0556 0.0548 0.0550 0.0566 0.0551 0.0580 0.0550 0.0538 0.0570 0.0559 X2 0.0543 0.0572 0.0570 0.0559 0.0554 0.0570 0.0570 0.0570 0.0570 0.0548 0.0550 0.0560 0.0569 0.0570 0.0580 0.0545 0.0525 0.0570 0.0581 0.0551 0.0580 0.0547 0.0556 0.0560 0.0576 1 X3 0.0554 0.0576 0.0551 0.0557 0.0565 0.0573 0.0585 0.0580 0.0566 0.0550 0.0560 0.0580 0.0565 0.0560 0.0560 0.0545 0.0560 0.0570 0.0587 0.0580 0.0580 0.0551 0.0546 0.0560 0.0570 X4 0.0576 0.0554 0.0550 0.0530 0.0566 0.0554 0.0550 0.0560 0.0552 0.0554 0.0560 0.0565 0.0556 0.0590 0.0558 0.0540 0.0550 0.0556 0.0558 0.0570 0.0550 0.0550 0.0543 0.0570 0.0575 (a) Construct X and R charts for these data. (b) Are there any points outside the control limits on the R chart? What does this say about the stability of the process? (c) Using Nelson’s eight rules are there any out-of-control signals given by the X chart? If so, where? What does this say about the stability of the process? (d) Construct a histogram for the data and comment on how many measurements are outside the specification limits. (e) What else can be said about the capability of the process now, and in the future? 2. One of the variables that affects customers’ perception of the quality of an automobile is the flushness of the top flange of a car door with the side surround of the body. Specifications call for a target flushness of 0 with limits of ±1.5 mm. (a) Initially, 50 consecutive automobiles are measured for fitness. The data are summarized using JMP, control charts and capability analysis: Flushness 1. Comment on the stability and capability of the process. Use the alarm rule of one point outside control limits. (b) A design change, installation of a rubber piece on the lower inside flange, is implemented and another 50 consecutive automobiles are measured. Refer to the JMP output that has control charts and capability analysis: Flushness 2. Comment on the stability and capability of the process. Again, use the alarm rule of one point outside control limits. (c) Has the design change improved the process? Be sure to comment on both the mean and the variation. Back up your answer with summary measures. (d) Is there more room for improvement? Discuss briefly. 2