STAT 495, Fall 2003 Homework Assignment #6

advertisement

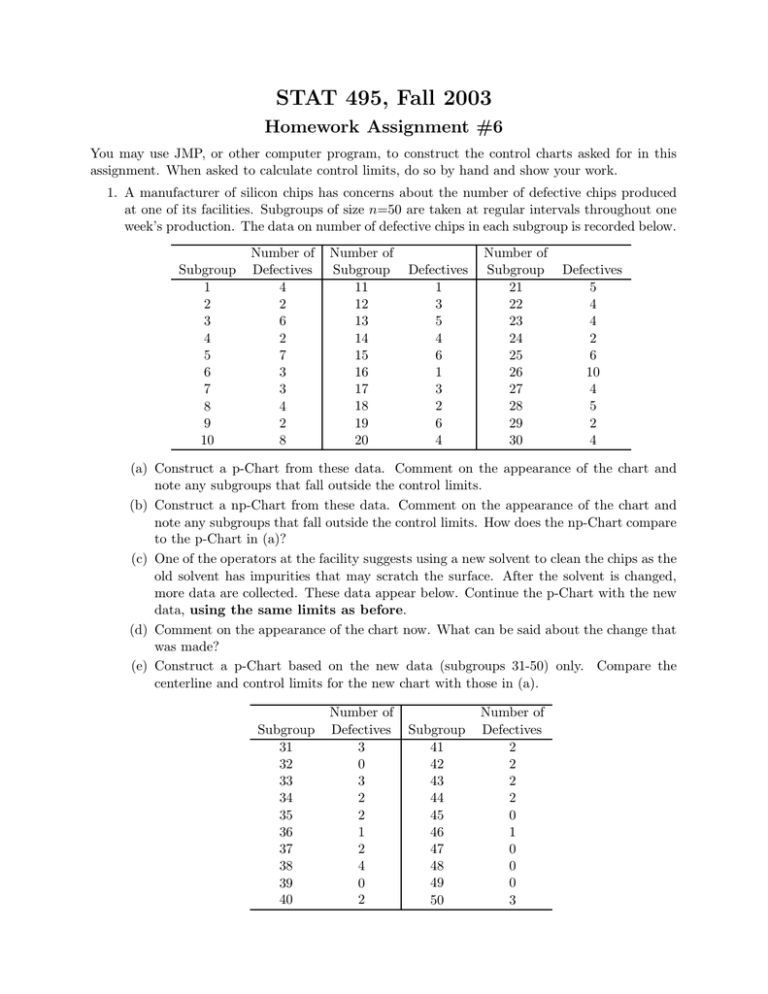

STAT 495, Fall 2003 Homework Assignment #6 You may use JMP, or other computer program, to construct the control charts asked for in this assignment. When asked to calculate control limits, do so by hand and show your work. 1. A manufacturer of silicon chips has concerns about the number of defective chips produced at one of its facilities. Subgroups of size n=50 are taken at regular intervals throughout one week’s production. The data on number of defective chips in each subgroup is recorded below. Subgroup 1 2 3 4 5 6 7 8 9 10 Number of Defectives 4 2 6 2 7 3 3 4 2 8 Number of Subgroup 11 12 13 14 15 16 17 18 19 20 Defectives 1 3 5 4 6 1 3 2 6 4 Number of Subgroup 21 22 23 24 25 26 27 28 29 30 Defectives 5 4 4 2 6 10 4 5 2 4 (a) Construct a p-Chart from these data. Comment on the appearance of the chart and note any subgroups that fall outside the control limits. (b) Construct a np-Chart from these data. Comment on the appearance of the chart and note any subgroups that fall outside the control limits. How does the np-Chart compare to the p-Chart in (a)? (c) One of the operators at the facility suggests using a new solvent to clean the chips as the old solvent has impurities that may scratch the surface. After the solvent is changed, more data are collected. These data appear below. Continue the p-Chart with the new data, using the same limits as before. (d) Comment on the appearance of the chart now. What can be said about the change that was made? (e) Construct a p-Chart based on the new data (subgroups 31-50) only. Compare the centerline and control limits for the new chart with those in (a). Subgroup 31 32 33 34 35 36 37 38 39 40 Number of Defectives 3 0 3 2 2 1 2 4 0 2 Subgroup 41 42 43 44 45 46 47 48 49 50 Number of Defectives 2 2 2 2 0 1 0 0 0 3 2. Ceramic boards for classrooms are produced in 4 foot by 8 foot sheets. The production manager is concerned about the surface defects on the sheets. Below are the data. Day Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Number of Boards 1 5 2 3 2 2 3 1 1 3 4 3 3 4 Number of Defects 2 5 3 8 1 4 8 0 2 8 5 7 4 6 Day Number 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Number of Boards 6 3 5 4 7 3 4 2 5 2 2 1 2 3 Number of Defects 18 6 8 17 4 6 4 5 2 5 0 15 3 5 (a) Compute the average number of defects per day. (b) Calculate the upper control limit (UCL) and lower control limit (LCL) for a c-Chart for the number of defects. Construct the c-Chart. (c) Are there any days that plot outside the control limits? If so, what days are they and how many defects are there on those days? (d) Another way to chart this data is with a U-Chart for the rate of defects per board. Compute the average rate of defects per board. (e) Because of the unequal number of boards inspected each day, the U-Chart will have different limits for each day. Calculate the upper and lower control limits for day 15. Construct the U-Chart. (f) Looking at the U-Chart of surface defects on ceramic boards, are there any days that plot outside the control limits? If so, what days are they and what is the rate of defects on each of those days? (g) Which chart, the c-Chart or the U-Chart gives a more accurate picture of the process that is producing the ceramic boards? Explain briefly.