Document 11566163

advertisement

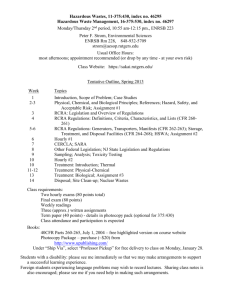

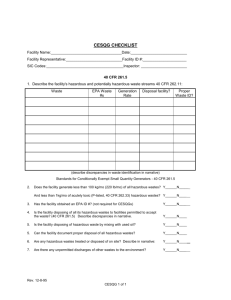

CE 529 Hazardous Waste Management Lecture 2 - Environmental Legislation – RCRA 2.0 S.K. Ong Generator Standards (40 CFR Part 262) Generator - is any person or entity whose act or process produces a hazardous waste or whose act first causes a hazardous waste (HW) to be subject to regulation Three categories: LQG - SQG CESQG - large quantity generator - produces more than 1,000 kg of HW or 1 kg of acutely HW in a calendar month Generates in any single month or accumulates at any time, 1 kg of RCRA acute hazardous waste Generates or accumulates any time more than 100 kg of spill cleanup material contaminated with RCRA acute hazardous waste small quantity generator, sometimes known as medium quantity generator - 100 to 1,000 kg of HW or less than 1 kg of an acutely HW in a calendar month conditionally exempt small quantity generator - no more than 100 kg of HW Generator status is determined on a month by month basis. For example, a generator produces 90 kg of HW one month is CESQG but if he produces 1,200 kg in the following month, the generator is subject to the full LQG requirement 2.1 • • • • • • • • • • • • 2.2 • • • • Large Generator Requirements must properly store waste, have an emergency and contingency plan and training of personnel must determine if the waste is a hazardous waste, conduct necessary analysis obtain an EPA ID and should not offer waste to transporters or TSDFs which do not have an EPA ID provide proper packaging, labeling, marking of packaged wastes to identify characteristics and dangers associated with the waste HW transported must be accompanied by a HW manifest that accompanies the waste from point of origin to point of final disposal Within 30 days of arrival of the HW with its manifest, the TSDF must send a copy of the manifest with all appropriate signatures and information to the original generator. If manifest fails to arrive after 35 days, the LQG must investigate and notify the EPA copies of the manifest must be retained by the generator, transporter, or TSDFs for three years must also keep records of all test results and waste analysis or any records made in accordance with the hazardous waste determination must prepare and submit a biennial report by March 1 of each even-numbered year - describing the quantity and type of waste shipped-off site and a description of the efforts taken during the year to minimize the volume and toxicity of waste generated CESQGs are not subject to these record keeping SQGs are subject to all record keeping requirements except for the biennial reporting requirements Responsibilities of CESQGs include: identification of the waste, not to accumulate more than 999 kg of HW at any time, treat and dispose of waste on site or sent to a permitted TSDF, municipal or industrial solid waste facility or recycling facility Transporters Requirements (40 CFR 263) Transporters are regulated both by EPA and the US DOT through the Hazardous Materials Transportation Act (P.L. 93-633 49 USC 1801 et seq.). DOT regulations are set forth in volume 40 CFR and cover shipment, regulating container manufacturing, and transportation, including highway, railway, water and air. Procedures are specific to the type of waste and the mode of transportation transporters must obtain an EPA ID number the transporter is responsible for following the manifest tracking system by not accepting waste without a manifest, insuring that the manifest is signed by the accepting TSDF and retaining a copy for three years (49 CFR) transporters are expected to prepare to handle an accidental discharge to reduce harm to human health or the environment • be prepared to accept responsibility for clean-up of contamination ___________________________________________________________________________________________ CESQG SQG (or MQG) LQG ____________________________________________________________________________________________ Quantity < 100 kg/mo 100 - 1000 kg/month 1000 kg/month or greater • EPA ID No. not required Required Required Management of waste State approved or RCRA permitted RCRA-permitted facility RCRA-permitted facility On site storage May be accumulated up to 999 kg May accumulate up to 6,000 for up to 180 days (or 270 days if transport of waste to TSDFs is over 200 miles) May accumulate any quantity up to 90 days Storage Requirements None Basic requirements with the technical standards under Part 265 for containers or tanks Full compliance with technical standards under Part 265 for containers or tanks Manifest Not required* Required Required Exception Report Not required Required after 60 days Required after 45 days Biennial Report Not required Not required Required Basic training required Full training required Personnel Training Not required Emergency/ Not required Basic plan required Full plan required Contingency plan * although not required legally under RCRA, many transporters will not handle hazardous waste without these items 2.3 TSDFs Requirements (40 CFR 264 (final status) and 265 (interim status) • any person who treats, stores or disposes of HW is considered as owner or operator of a treatment, storage, or disposal facility (TSDF). • Facilities classified as TSDFs include landfills, above ground tank systems, surface impoundments, waste piles, land treatment, incinerators, other thermal treatment units, chemical, physical and biological treatment units and underground injection wells. Technical requirements for the above facilities are covered under subpart J to X of 40 CFR 264. • On the effective date of RCRA regulation (Nov. 19, 1980) all treatment, storage or disposal of HW was prohibited unless the operations were authorized by a RCRA permit or excluded. • However, this would create a disastrous situation for the existing HW management program. Therefore, Congress established an interim status provision whereby facilities existing on or before Nov. 18, 1980 are eligible for interim status until a final application is filed and approved. • The application process for TSDFs include a Part A and a Part B application. Part A includes administrative information while Part B of the application is specific to the type of the facility and includes technical information on the facilities. Interim status facilities are covered by 40 CFR 265. • All existing TSDFs if they would like to continue operations after Nov. 19, 1980 would be required to submit Part A application . This must then be followed by the Part B in which EPA will determine whether a final permit should be granted. • for new facilities established after Nov. 18, 1980, must submit final Part A and B application simultaneously, must meet 40 CFR 264 technical standards. After application is approved, draft permit is prepared. EPA then solicit written public comments and hold public hearings for 45 days. Following comment period, EPA will issue the RCRA permit decision. If approved, usually a 10-year permit is issued. 2.3.1 Exemptions (40 CFR 264.1) • facilities that are state-approved to exclusively handle SQG wastes • operation of a facility managing recyclable materials • farmer disposing of waste pesticides in compliance with 40 CFR 262.51 • total enclosed treatment facility as defined in 40 CFR 260.10. Exemption is for the unit itself, not the effluent. • operations that accumulate waste on site for 90 days or less • operations of an elementary neutralization unit or a wastewater treatment unit • transporter storing manifested HW in containers for less than 10 days • operations that engaged in treatment or containment activities during immediate response for a HW spill or discharge • the addition of adsorbent material to waste or the addition of waste to adsorbent material 2.3.2 Requirements of a TSDFs • need an EPA Identification number • personnel must be properly trained in handling of waste and health and safety • develop a communication and alarm system • develop a security system to prevent unauthorized entry • must be in compliance with local, state and federal standards • must maintain complete and accurate records of its operation • provide adequate ground water monitoring throughout the life of the facility. • during period of closure, TSDF must completely process all on-site waste and place a final cover over the landfill • Following closure, for landfills, land treatment, surface impoundments and certain waste piles, a 30 year post closure period commences during which the TSDF facility must continue to monitor the groundwater and conduct any maintenance activities • must provide adequate liability coverage to compensate third parties for injury or property damage. 2.4 Land Disposal Restrictions 2.4.1 General description • In 1984, Congress amended RCRA to tighten restrictions on the disposal of hazardous waste in land disposal facilities, such as landfills, surface impoundments, waste piles, land farming areas, injection wells, salt dome or salt bed formation, underground mine or cave, or concrete vault or bunker. (See 40 CFR Part 264 and Part 148 for underground injection wells). • Intentions of the land ban restrictions are to substantially reduce the toxicity of the wastes; reduce the likelihood that hazardous constituents of the wastes will migrate from a land disposal unit; and to promote waste minimization and recycling; and to prevent TSDFs from becoming future CERCLA (Superfund) sites. • The amendments immediately banned the placement of certain types of HW in land disposal units and set forth a time schedule for banning the remainder of HW from land disposal, unless the HW had first been treated with the best demonstrated available technologies (BDAT) as identified in the regulations. • As of August 2, 1990, all hazardous waste as identified in 40 CFR are land banned unless treated to meet BDAT standards. • Also land banned wastes may not be stored at a facility for more than one year. • Generators shipping RCRA HW to TSDFs or recyclers do not need to meet treatment standard criteria • A waste disposed of prior to an applicable effective date does not have to be removed for treatment. However, if the waste is removed from the unit after the effective date, it must meet all applicable treatment standards before subsequent placement in or on land • Land ban regulations do not apply to small quantity generators ( i.e., generators of less than 100 kg/month of HW or 1 kg/month of acutely HW). In HSWA, Congress require EPA to set a schedule to develop treatment standards for HW. For each hazardous waste, EPA established a treatment standard that is protective of human health and the environment when the wastes are land disposed. The treatment standards either: • require the use of one or more specified treatment technologies, or • they require wastes to be treated to meet certain concentration limits on hazardous constituents. When concentration limits are used, EPA assumes that a waste will be treated with the BDAT. Although such wastes can be treated by any technology, the concentration of hazardous constituents in any treatment residues cannot be higher than those obtained using BDAT. Concentration limit can be expressed as a concentration in the waste extract (TCLP) or as a total concentration of the constituents in the waste. Treatment Standard criteria are given in 40 CFR 268.41. 268.42 or 268.43. • Congress divided HW into six groups as follows: Groups Solvents and Dioxins California List Wastes First Third of Listed Wastes+ Second Third of Listed Wastes+ Third Third of Listed Wastes & Characteristics Wastes+ Newly identified wastes Publication Date of Final Rules Nov. 8, 1986 July 8, 1987 Aug 8, 1988 June 8, 1989 May 8, 1990 Within 6 months of identification as a HW + Listed wastes were divided up into high volume - high hazard and low volume - low hazard wastes. • Storage Prohibition - Storage of restricted waste is prohibited except to accumulate sufficient quantities to facilitate proper treatment, recovery, or disposal. (40 CFR 268.50). For the first year of storage EPA bears the burden of demonstrating that wastes are being stored unnecessarily. After one year, the burden shifts to the waste owner to demonstrate the necessity for longer storage. • Dilution Prohibition - (40 CFR 268.3) - the general rule that EPA applies is that if a listed and characteristic waste is placed in a land disposal unit, the dilution prohibition applies between the point of generation to the point of disposal. However, there are exceptions to this rule. 2.5 Corrective Action Process In HSWA, release of HW at RCRA facilities are regulated through the corrective action process. • • • • Section 3004 (u) allows EPA to require corrective action for all releases of HW or constituents from " waste management units" regardless of when the waste was placed in the units, i.e., including releases by previous owners or operators Section 3004 (v) authorizes EPA to impose corrective action requirements for releases which migrate beyond facility boundaries Section 3004 (h) authorizes EPA to impose corrective action whenever there is or has been a release of hazardous waste from an interim status RCRA facility - regardless of the time at which waste was placed in the facility and regardless of whether the current owner/operator was responsible for the release. (40 CFR 264 Subpart F outline regulations for corrective actions for releases to ground water from regulated units) EPA has estimated that approximately 2,000 TSDFs may require some form of corrective action (note that these are generally facilities established before Nov. 19, 1980). Cost estimates by EPA are: Immediate Cleanup to Background $490 billion Immediate Cleanup to Health-based Standards $ 41.8 billion • Corrective actions requirements are imposed through permits or enforcement orders. • Several definitions are provided under the corrective action process: (a) a regulated unit is defined as any surface impoundments, waste piles, land treatment units or landfill that received waste after July 26, 1982. (b) a solid waste management unit (SWMU) is defined as any waste management unit from which HW or constituents may migrate even if the unit was not intended for the management of HW. This include any areas that become contaminated as a result of routine systematic releases from process/industrial discharges. Note : a regulated unit is a subset of SWMUs (c) a corrective action management unit (CAMU) means a contiguous area within a facility as designated by the regional administrator for the purpose of implementing corrective action requirements which is contaminated by HW 2.5.1 Components of Corrective Action Process The corrective action process consists of four main components: 1. RCRA Facility • preliminary investigation to identify SWMUs and Assessment (RFA) collect existing information and identify contaminant releases that needs further investigation • a visual site inspection and sampling visit • The following decisions will be made: (a) no further action (b) A RCRA facility Investigation (RFI) is required (c) Interim corrective measures by owner or operator to protect human health and the environment 2. RFI • may range from an examination of a small specific activity to a complex multimedia study • needs to verify any releases, characterize the release and interpret against health and environmental criteria to determine whether a corrective measure study (CMS) is necessary • Identify and implementation of interim corrective measures may also be conducted during the RFI 3. CMS • owner or operator will identify and recommend specific measures that will correct the release • examine effectiveness in achieving adequate control of sources and cleanup • assessment of time and costs required to implement remedies 4. Remedy Selection (RS) • remedies selected based on the following: (i) protective of human health and the environment (ii) attain media cleanup standards (iii) control sources of releases to reduce or eliminate threats (iv) comply with applicable HW management regulations 5. • includes designing, construction, operating, maintenance and monitoring selected corrective measures • financial assurances must be demonstrated prior to implementation • requires a cleanup to satisfactory standards according to EPA CMI (Corrective Measures Implementation) 2.5.2 • • Cleanup Requirements for Corrective Actions EPA has not established national uniform standards for cleanup per se. EPA-recommended limits or factors for closure of TSDFs are usually used as cleanup levels. • These factors are health-based levels and for carcinogens must be clean up until the risk range is of 10 -4 to 10-6 exists. Clean Closure Cleanup Levels _________________________________________________________________________ Media EPA recommended limits or factors _________________________________________________________________________ Groundwater MCLs*, if nonexistent, oral RfDs* for oral noncarcinogenic constituents, and CSFs* for carcinogens. Carcinogens must be in the risk range of 10-4 to 10-6 If above limits or factors are nonexistent, can use either natural background levels or conduct testing in compliance with TSCA to develop a health-based standard. if the background levels are elevated, may use detection limit. Surface Water If surface water is used as a drinking water source, use MCLs, if nonexistent, use RfDs and CSFs. Use Ambient Water Quality Criteria (WQC) to determine if protective of the environment (aquatic species). Soil Use oral RfDs and CSFd Air National Ambient Air Quality Standards (NAAQs); if nonexistent, use inhalation RfDs and CSFs. __________________________________________________________________________ MCL - Maximum contaminant level; RfD - reference dose; CSF - carcinogenic slope factor 2.6 RCRA Subtitle I - Underground Storage Tanks (USTs) USTs are regulated under HSWA Subtitle I. USTs regulations are found in 40 CFR 280. • • • • • • • • An estimate by EPA shows that there are approximately 2 million UST systems at 700,000 facilities in the US. About 25% are leaking. USTs are considered to be one of the major sources of groundwater contamination in the country. Unlike the purpose of RCRA, these regulations apply to USTs for storage of useful materials and in addition to those used for wastes UST is defined as "any one or combination of tanks (including underground pipes connected thereto) which is used to contain an accumulation of regulated substances and the volume of which.is ten percent or more beneath the surface of the ground. Excluded are home heating oil tanks, septic tanks. USTs on farms or residential homes with less than 1,100 gallons capacity which are used for non commercial purposes UST regulations mandate all tanks and piping to have corrosion protection. leak detection system, spill/overfill prevention system UST regulations distinguish between "new" and "old" tanks. Existing tanks are those which were installed prior to Dec. 22, 1988. All new tanks must meet proper installation requirements Depending on the age and condition of the existing tank, some requirements such as leak detection systems and cathodic protection must be met by 1998. Owners and operators must comply with reporting and record-keeping requirements. Owners must report releases, take immediate action to prevent further release, and identify and mitigate any further hazards -- some actions that are needed include a corrective action plan, site characterization, free product removal, soil and groundwater investigations owners must show sufficient funds to cleanup leaks and to compensate third parties for damage suffered as a result of a leak. For most owners, this means that they must have at least $1 million per occurrence insurance coverage (Part 280.93)