(Jv ,&, /Y72 for the presented on

advertisement

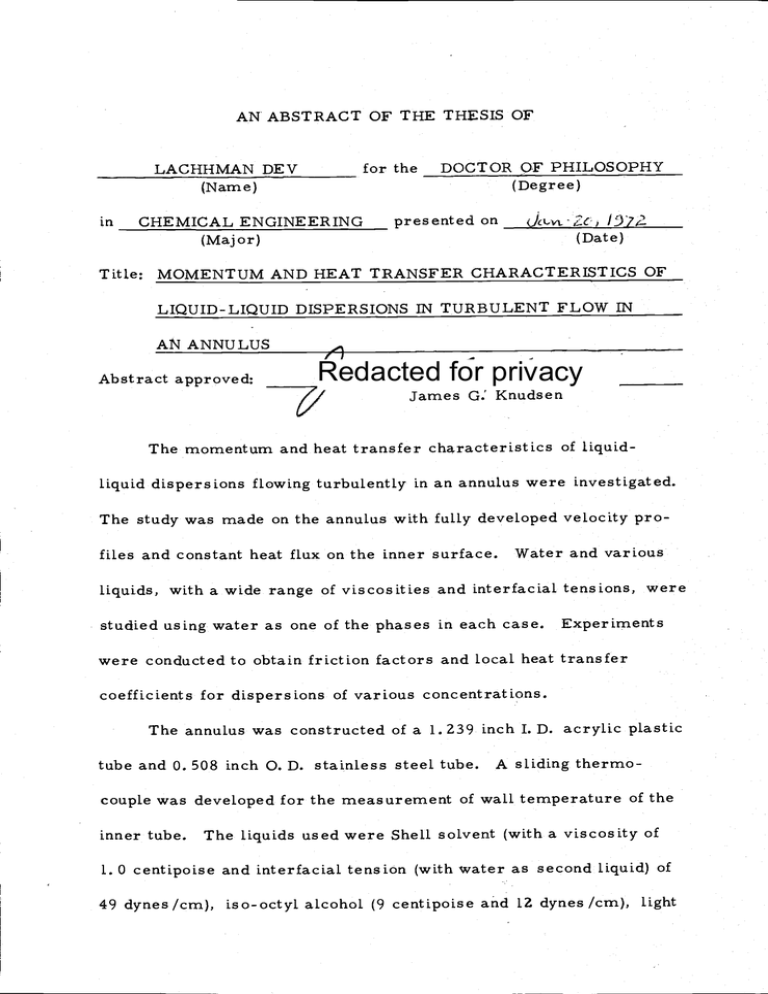

AN ABSTRACT OF THE THESIS OF

LACHHMAN DEV

(Name)

in

for the

CHEMICAL ENGINEERING

DOCTOR OF PHILOSOPHY

(Degree)

presented on

(Jv ,&, /Y72

(Date)

(Maj or)

Title: MOMENTUM AND HEAT TRANSFER CHARACTERISTICS OF

LIQUID-LIQUID DISPERSIONS IN TURBULENT FLOW IN

AN ANNULUS

Abstract approved:

Redacted for privacy

James G. Knudsen

The momentum and heat transfer characteristics of liquidliquid dispersions flowing turbulently in an annulus were investigated.

The study was made on the annulus with fully developed velocity pro-

files and constant heat flux on the inner surface. Water and various

liquids, with a wide range of viscosities and interfacial tensions, were

studied using water as one of the phases in each case. Experiments

were conducted to obtain friction factors and local heat transfer

coefficients for dispersions of various concentrations.

The annulus was constructed of a 1.239 inch I. D. acrylic plastic

tube and 0. 508 inch 0. D. stainless steel tube. A sliding thermocouple was developed for the measurement of wall temperature of the

inner tube. The liquids used were Shell solvent (with a viscosity of

1. 0 centipoise and interfacial tension (with water as second liquid) of

49 dynes/cm), iso-octyL alcohol (9 centipoise arid 12 dynes/cm), light

oil (15 centipoise and 54 dynes 1cm), and heavy oil (ZOO centipoise and

48 dyries/cm). Reynolds number ranged from 10, 000 to 100, 000,

It was found that the friction factors could be expressed by

Rothfus and coworkers' equation for single phase fluids. An effective

viscosity was obtained from the friction factor data at three tempera-

tures. Heat transfer data were correlated by Monrad and Pelton's

equation in the following form.

(St)(Pr) /

=

0. OZ (D2 /D1)°'

(Re)°

Z

AlL properties were evaluated at the bulk temperature. The Reynolds

number was based on the effective viscosity. The Prandtt number and

C

p

used were those of the continuous phase.

For the prediction of effective viscosity, a correlation was

developed that takes into account the variation of relative fluidity with

temperature.

The thermal entry length was found to depend on the continuous

phase Prandtl number. There was no systematic variation of the entry

length with respect to the Prandtl number based on the mixture proper-

ties.

The heavy oil dispersions behaved differently particularly at

high concentrations and high temperatures. Use of predicted effective

viscosities in the calculation of friction factors and heat transfer

coefficients resulted in large deviations from the experimental values.

These deviations were attributed to the difference in drop size and

drop size distribution of the heavy oil dispersions.

A study was made of a water-in-solvent dispersion containing

about 94 percent solvent by volume. The viscosity of this dispersion

was found to be very close to that of the pure solvent indicating that

it behaves differently compared to a dispersion having water as the

continuous phase under the same conditions.

Momentum and Heat Transfer Characteristics of

Liquid-Liquid Dispersions in Turbulent

Flow in an Annulus

by

Lachhman Dev

A THESIS

submitted to

Oregon State University

in partial fulfillment of

the requirements for the

degree of

Doctor of Philosophy

June 1972

APPROVED:

Redacted for privacy

Redacted for privacy

Head of Department of Chemical Engineering

Redacted for privacy

Dean of Graduate School

Date thesis is presented

()&M

,

Typed by Mary Jo Stratton for Lachhm3n Dev

DEDICATION

To the memory of my daughter Amita

ACKNOWLEDGMENTS

I wish to extend my grateful appreciation to the following:

To Dr. James G. Knudsen, associate dean of engineering for

his generous assistance and useful suggestions during the course of

this investigation.

To the National Science Foundation for its financial assistance.

To the department of Chemical Engineering, Charles E. Wicks,

head, for the use of its facilities.

To Mr. William B. Johnson for his helpful suggestions and aid

in construction of the equipment.

To Sudershana for her patience and encouragenent.

TABLE OF CONTENTS

Page

INTRODUCTION

1

LITERATURE SURVEY AND THEORETICAL

BACKGROUND

Flow of Single-Phase Fluids

Two-Phase Flow

Turbulent Flow of Non-Newtonian Fluids

Heat Transfer to Single Phase Fluids

Heat Transfer to Liquid-Liquid Dispersions

Heat Transfer to Non-Newtonian Fluids

3

9

13

16

19

21

EXPERIMENTAL PROGRAM

24

EXPERIMENTAL EQUIPMENT

26

Supply Tank and Pump

Piping System

Test Section

28

28

29

Temperature Probe

33

EXPERIMENTAL PROCEDURE

37

SAMPLE CALCULATIONS AND ERROR ANALYSIS

40

Pressure Drop and Friction Factor

Heat Transfer

Analysis of Experimental Errors

DISCUSSION OF RESULTS

Friction Factor Data

Heat Transfer

Thermal Entry Length

Water in Oil Dispersions

40

44

48

57

57

72

79

81

CONCLUSIONS

84

RECOMMENDATIONS FOR FURTHER WORK

87

Page

BIBLIOGRAPHY

88

APPENDICES

Physical Properties

Relationship Between Wall Temperatures

on the Inside and Outside of the Core Tube

Heat Loss from the Test Section

Mean Deviation of Dispersion Concentration

Thermal Entry Length Data

Observed and Calculated Friction Loss and

Heat Transfer Data for Water, Solvent,

andSS94.1

Progress of Mixing Data

V1II. Observed and Calculated Data for Dispersions

Having Water as the Continuous Phase

Computer Programs

Nomenclature

93

100

102

105

107

111

117

119

153

162

LIST OF TABLES

Page

Table

1

Summary of experimental program.

25

2

Effective viscosities and relative fluidities.

62

Comparison of Nusselt numbers predicted by

Quarmby, Monrad and Pelton at Pr = 10,

R2/R1 = 2.88.

72

4

Thermal entry lengths.

80

5

Physical properties of heavy oil.

95

6

Physical properties of iso-octyl alcohol.

96

7

Physical properties of light oil.

97

8

Physical properties of Shell solvent 345.

98

9

Effective density of the manometer liquid.

99

3

10

Mean deviation of dispersion concentration.

106

11

ThermaL entry length data.

108

12

Observed and calculated friction factor data

for water, solvent, and SS94. 1.

112

Observed and calculated heat transfer data

forwater, soLvent, and SS94. 1.

114

14

Progress of mixing data.

118

15

Observed and calculated friction factor data.

120

16

Relative fluidities.

130

17

Predicted outerwall friction factors.

134

18

Observed and calculated heat transfer data.

143

13

LIST OF FIGURES

Page

Figure

1

Schematic flow diagram.

27

2

Detail of test section.

30

3

Temperature probe.

35

4

Friction factor plot for water.

58

Outer wall friction factor plot for water,

solvent and SS94. 1 dispersion.

59

6

Progress of mixing.

60

7

Error plot for outer wall friction factor

using experimental effective viscosities.

63

8

Relative fluidities.

65

9

Error plot for outer wall friction factor

using Equation (23) for effective viscosity.

66

versus

68

5

10

Plot of

11

Corrected relative fluidities.

12

Errorplot for outer wall friction factor

e2

using Equation (78) for effective viscosity.

13

14

15

70

71

Heat transfer results for water, solvent

and SS94. 1 dispersion.

73

Error plot for heat transfer using experimental effective viscosities.

75

Error plot for heat transfer using Equation

(23) for effective viscosity.

77

Page

Figure

16

17

Error plot for heat transfer using Equation

(78) for effective viscosity.

78

Temperature profile along the heated length

for SS4. 7 dispersion.

82

MOMENTUM AND HEAT TRANSFER CHARACTERISTICS

OF LIQUID-LIQUID DISPERSIONS IN TURBULENT

FLOW IN AN ANNULUS

INTRODUCTION

The flow and heat transfer characteristics of two iminiscible

liquids moving in a duct are of fundamental as well as of practical

interest. Such systems are encountered widely in the chemical and

petroleum industries. The design of tubular reactors, liquid-liquid

extraction equipment and liquid transport systems depends upon a

knowledge of the flow and heat transfer characteristics of these liquidliquid mixtures. Fundan-iental knowledge of the heat, mass and

momentum transport between the phases as well as between the two

phase liquid and the tube wall is necessary and depends on the

physical properties of the liquids and the state of division of the

dispersed phase.

While much attention has been given to the gas-liquid mixtures,

little has been devoted to the liquid-liquid situation. Literature

references on the latter are less by at least one order of magnitude

than are available for the former. All the previous work on liquidliquid dispersions has been restricted to the study of the flow and heat

transfer in pipes. The effect of temperature on the properties of the

dispersion has not been investigated to an appreciable extent.

The present work is concerned with the study of dispersions in

2

turbilerit flow in an annul.us. This is a flow geometry of considerable

technical interest. Equipment was designed and built for the measurement of friction factors nd local heat transfer coefficients. The

study has been made on an annulus, of radius ratio R1 /R2 of O 41,

with fully developed velocity profiles and constant heat flux on the

inner surface (core). Four organic liquids were investigated to cover

a wide range of properties (viscosity and surface tension). These are:

a commercial solvent, iso-octyl alcohol, a light oil and a heavy oil.

The study was made over a temperature range of 70-160°F. The

friction factor measurements were made to evaluate the effective

viscosity of the dispersion. This viscosity was then used for the

correlation of heat transfer data. A relationship is proposed for the

prediction of relative fluidity. The expression takes into account the

variation of relative fluidity with temperature.

3

LITERATURE SURVEY AND THEORETICAL BACKGROUND

Flow of Single-Phase Fluids

In analyzing flow problems the energy, momentum and continuity

equations are solved with given boundary conditions. For steady, iso-

thermal, fully developed incompressible flow energy equation for

macroscopic flow may be written as follows for a unit mass of flowing

fluid.

(Va)

+

p

zrg

+

=

Equation (1) is frequently referred to as Bernoulli's equation when w

and 1w are zero.

For one-dimensional flow in the z direction, the continuity

equation may be written

d(pAV)

d

For a conduit of uniform cross-section containing nopumps or

turbines, equation (1) can be reduced to

- + -EP

p

-

z = - 1w

(3)

A large number of experimental determinations on turbulent flow

of fluids have led to the following quadratic resistance law;

F -

fpVA'

2g

fpV2Lp

-

(4)

4

where F is the resisting force at the wall of the conduit, A' is surface

area of the wall at which F acts, L is the length of the tube, p is the

wetted perimeter, and f is a proportionality factor known as the

Fanning friction factor.

The energy required to overcome the frictional force in moving

the fluid through the tube a distance 6 L is F 6 L. This energy is

dissipated in a mass of fluid pA&L. Hence, the energy dissipated

as friction losses per unit mass of flowing fluid is

1w =

FÔL

pAÔL

(5)

ZfLV2

-.

g(4A/p)

Substituting this expression for 1w in the energy equation (3) one

obtains

LhP +

ZfLV2 p

tg z

-

g(4A/p)

For the case of a horizontal pipe of diameter D, this reduces to the

familiar Fanning equation,

-p =

f

ZfLV2

Dg

= the pressure drop due to friction in force per unit area.

where

The term 4Afp in equation (6) is known as the equivalent diameter, D, for

the conduit. For an annulus, consisting of an outer tube with inside

diameter D and an inner tube with outside di3meter D ,

2

1

D

e

is D 2

The friction factor may be defined for annuli using this equivalent

diameter.

D

-g(D2 - D1)

P

(8)

2

ZpV L

-

Pf is the pressure change due to frictional effects alone and may be

written as

f

pgz

=

(9)

By dimensional analysis i,t can be shown that for smooth annuli

the friction factor is a function of the Reynolds number and the dia-

meter ratio D2/D1. However, extensive investigation has failed to

produce a satisfactory correlation involving the diameter ratio.

In the discussion which follows, the Reynolds number for annuli

is based on the equivalent diameter D2 (D2 - D1 ) Vp

(10)

Re

Davis (1943) made a comprehensive study of all existing annular

friction-factor data and proposed the following equation:

D2/D -1

D2''D

-0. 1

=

0. 055(Re)

02

(11)

1

According to this reLationship, f has a higher value than for plain tube

at the same Reynolds number. Davis' expression has the drawback

that it does not reduce to the value for the parallel plate channel as

D2/D1 approaches unity.

Rothfus, Monrad, Sikchi and Heideger (1955) defined inner- and

6

outer-wall friction factors for annuli and correlated friction-loss data

over a Reynolds-number range from 10,000 to 45, 000. The inner- and

outer-wall friction factors are, respectively,

2 T1 g

=

pV

2

2

=

pV

2

is expressed as

(R2 - R2 ) g

2

m

R2pV

c

(Pf/L)

where R 2 is the inner radius of the outer tube and Rm the radius

corresponding to the point of maximum velocity.

Rothfus and coworkers report that for 10, 000 <Re2 <45, 000 and

for long annuli

1

-

4, 0 log (Re2 '[) - 0. 40

where

2(R

Re 2

-

R2)Vp

R2

(16)

Equation (15) is identical to Nikurads&s (1932) well known

friction factor relationship for smooth tubes.

Deissler and Taylor (1955) made a theoretical study of flow in

eccentric and concentric plain annuli and showed that the friction factor

7

decreases as the eccentricity of annulus is increased.

Recently several interesting theoretical (Meter and Bird, 1961;

Macagno and McDougall, 1966; Rothfus, Sartory and Kermode, 1966;

Levy, 1967; Clump and Kwanoski, 1968; Quarmby, 1968; Randhawa,

1969) and experimental (Brighten and Jones, 1964; Jonsson and

Sparrow, 1966; Quarmby, 1967) studies of turbulent flow in annuli

have been made. Brighten and Jones (1964), in what appears to be a

careful and extensive study on flow in annuli with smooth walls,

conclude that the friction factor depends only on the Reynolds number

and is independent of the radius ratio, a, at least for a > 0. 0625.

These workers obtained friction factors slightly higher (1 to

10

percent) than friction factors for pipe flow at corresponding Reynolds

numbers for the ReynoLds number range 4000 - 327, 000. The Bias ius

(1913) equation

f

=

0.079

Re°

(17)

for pipe flow was used for comparison.

Of particular importance is their study in the region of rnaxi-.

mum velocity and the result that the location of the point of maximum

velocity is nearer the inner pipe wall than that for laminar flow. The

point of maximum velocity can be calculated from the following

equations obtained by Clump (1968) who applied standard polynomial

curve-fitting techniques to the data of Brighton and Jones. Although

the data indicate a slight Reynolds number effect at small core-to-shell

8

ratios, this effect was excluded.

R2-R

R

m

=

R + (

1

2

1)11.08 (R lB )3 - Z.Z0(R /R

12

12

)2

(18)

+ 1.65 (R1 /R2) + 0.48]

for core-to-shell ratios between 0. 0625 and 1, and

Rm

B1 [18.1(R2-R1)J(R11R2)

(19)

for core-to-shell ratios less than 0.0625,

The results of Quarmby (1967) agree with Brighten and Jones

relative to the independence upon radius ratio but Quarmby's correla-

tion is closer to the relation for the plain tube (f

0.079

Re°' 25) than

those of Brighten and Jones and are in agreement with the upper limit

of f =

0.087

Re°

25

of the latter's data.

Macogno and McDougall (1966) extended the Prandtl-Karrnan

expression for the resistance coefficient of turbulent flow in circular

pipes to turbulent flow in both smooth and rough annular conduits and

obtained expressions for location of maximum velocity and average

as well as inner- and outer-wall resistance coeffidents. Their results

are in agreement with the experimental findings of brighten and Jones.

Quarrnby (1968) employed Von Krmn's similarity hypothesis

together with a description of the sublayer profile proposed by

Deissler to predict the friction factor - Reynolds number relationship

for annuli. His results show satisfactory agreement with the data of

Brighten and Jones.

Two-Phase Flow

The most general approach to the problem of two-phase flow is to

consider each phase separately, with common boundary conditions.

However, the problem can be considerably simplified if the systems

can be handled by the methods already developed for single-phase flow.

By considering the equations of motion, Baron, Sterling and Schueler

(1953) investigated the size of dispersed phase particle such that a

single phase equation might be applicable to the flow of the two phase

fluid. They considered the ratio of inertia forces to the drag forces

acting on the dispersed phase and arrived at the following criterion for

the applicability of single phase treatment.

(Re)c(dp/D)2

d"c <

1

(20)

where d is the particle diameter.

Application of equation (20) to a liquid-liquid dispersion flowing

in a 4-inch pipe at (Re) = 10, 000 indicates that the drop diameter

should be less than 1 mm.

From drop size distribution and effective viscosity measurements, Ward and Knudsen (1967) indicated that a suitable criterion for

the treatment of liquid-liquid dispersions as single phase fluids should

exist in the form

(Re)(d/D)2

d"c

<2

(21)

10

where d is the Sauter mean diameter. Equation (21) states that a

liquid-liquid dispersion can be treated as a single phase fluid if the

at a Reynolds number of 10, 000 and

drop size d is less than 320

100 i at a Reynolds number of 100, 000, Ward and Knudsen found that

well-mixed Shell solvent and light oil dispersions behaved similar to

homogeneous Newtonian fluids. Heavy oil dispersions having heavy

oil volume fractions above 10 percent behaved differently and velocity

profiles indicated non-Newtonian characteristics,

Petroleum solvent (Shell solvent) was also studied by Cengel

etal, (1962) and Faruqui and Knudsen (1962) in laminar and turbulent

flow conditions. Measured friction factors were used to calculate the

effective viscosities. In vertical turbulent flow all dispersions

behaved as Newtonian fluids. The 35 and 50 percent dispersions in

horizontal flow exhibited non-Newtonian characteristics and had effec-

tive viscosities considerably higher than the same dispersion in

vertical flow. This behavior was attributed to phase separation in the

horizontal tube.

Faruqui and Knudsen (1962), and Ward (1964) also measured the

velocity distribution of the flowing dispersions. The effective viscosity

in these cases was obtained by fitting the turbulent core point velocity

data to the equation

yu*

---251n

u* U

V

+5.5

(22)

11

This method provided satisfactory values of the dispersion viscosity

but does require rather extensive velocity distribution data.

Legan and Knudsen (1966) investigated the momentum and heat

transfer characteristics of liquid-liquid dispersions in turbulent flow

in pipes. For the dispersed phase, they used light oil and heavy oil.

They conclude that the friction losses of liquid-liquid dispersions

studied can be treated with existing single phase equations. By fitting

the friction factors to Blasius equation, 1

0.079 Re°

an effec-

tive viscosity of the dispersion was obtained. There was a deviation

of the data from a slope of -0. 25 at low flow rates for most dispersions which was attributed to either a non-Newtonian behavior or a

coalescence of the oil droplets to a size that the dispersion could no

longer be considered a homogeneous, single phase fluid. In analyzing

the data, all deviating points at low flow rates were not used,

The effective viscosity was correlated at room temperature by

the relationship

(23)

o

<4<

0.5 for

o

<4 <

0.1 for - 200

18

12

Data of Ward (1964), Faruqui (1962) and Cengeletal. (1962) agree

with the above relation,

In the case of heavy oil, the viscosity of 21 percent dispersion

was found to be lower than that of the 5 percent dispersion at the same

temperature. This anomaly was explained by a tislipli velocity of the

large drops relative to a fluid element in which they are contained.

Therelative fluidity was found to decrease significantly with

temperature.

Recently Soot (1971) has studied the two-phase liquid-liquid

flow in pipes. He also analyzed the data of Wright (1957), Cengel

(1959), Ward (1964), Faruqui (1962), Finnigan (1958), and suggested

the following empirical relationship for vertical turbulent bubble flow.

2

=

A 2.25 X 2 - 1.20

AcZ.Si (Reco)

c

where

(Red

0. 563

0.475

(24)

and X2 are the Lockhart-Mart inelli parameters defined as

4

follows:

tPf

2

Zft

c

c

2

W2L

c

2f' W2L

d

,

d

DA2p

'

=

d

Rec

o-

d

(26a, b)

DA2pd

DW

DW

Re

(25a, b)

FLA

(27a, b)

13

W is the mass flow rate.

Turbulent Flow of Non-Newtonian Fluids

The phenomenon of turbulent flow in non-Newtonian fluids has not

received nearly the attention accorded to the laminar flow regime.

However, in recent years the discovery of drag reduction in very

dilute solutions of polymers and increased interest in slurry handling

have resulted in the publication of several excellent articles on the

theoretical and experimental aspects of flow in pipes. While completely general solutions have not been developed, equations that may

be used for engineering calculations are available for many classes of

fluids. No work seems to have been done on the turbulent flow of nonNewtonian fluids in annuli.

Dodge and Metzner (1959) have extended the work of Von Karman

on turbulent-flow friction factors to include inelastic non-Newtonian

fluids. They derived an expression for the friction factor,

f, in

terms of the generalized Reynolds number (Re)':

-A

log [(Re)

+ cn

and

(Re)'

=

8(DnVZnP,K)

6n+ Z

(29)

For n = 1 the Reynolds number reduces to DVp4L. By analyzing

the experimental friction factor data for non-Newtonian liquids these

14

authors proposed that

A

For n =

1,

In

=

4.0/n075

=

-0,4/n'

equation (Z8) reduces to the well known Nikuradse equation.

Tornita (1959) developedcorreLations for use with Bingham

plastics and power law fluids. His general equation for friction factor

is

'.JT7

=

4. 0 log{Re x

/2 -0. 40

wheref and Re are given below for two types of fluids.

For Bingham plastics:

DPg

f

Zp L (1-c) V

a

(l-c)(c-4c+3)

]Vp

= Ty/Tw

Value of c is obtained from

V=

Rgc T

Ti

y

p

c 4-4c+3

lZc

where R is the radius of pipe, T is the yield stress and

p

the

"pIastic viscosity for Bingham plastic. For power law fluids:

1=

ZD P g(Zn+l)

(34)

3L p V

(3h+l)

15

11-n

Re

6[(3n+l)/nj

2n[(Zn+l)/nI

x

D

n

(V)

K

2-n

Although the experimental data supporting this last correlation

are much more limited than those of Dodge and Metzner, it does seem

to hold for a wide range of fluid-property parameters.

The preceding discussion dealt with purely viscous fluids, i, e.,

those that showed no elasticity. The phenomenon of drag reduction

in turbulent flow of viscoelastic materials has evinced considerable

interest in recent years, and is of major concern in designing flow

systems for such fluids. Data on a viscoelastic material have been

presented by Seyer and Metzner (1967). The friction factor is as much

as five times less than that predicted by equation (28) for purely

viscous non-Newtonian fluids of similar n. The friction factor shows

the effect of pipe diameter. The authors have also presented an

analysis for the interpretation of these superficially paradoxical

characteristics of viscoelastic polymer solutions.

Meyer (1966) analyzed the existing data and proposed a correla-

tion for predicting the frictional characteristics of turbulent flow of

dilute viscoelastic non-Newtonian fluids in pipes. Their relationship

is

1 /'[f

=

(4 + a /2) log Re ff - 0. 394

a

- -log

2 D u*cr

w

16

Alog2'+ B

B

A

=

BN + a Log

=

5.66

u*

(37)

u*

cr

B

n

=

cr

(38)

6.07

B is obtained from the velocity profile data. a is a fluid property

defined in equation (38). BN is the value of B for Newtonian fluids.

urn is the maximum flow velocity in the pipe. u* is the friction

velocity

sJ

Tw/p.

u*

cr

is the critical value of u*, taken as 0. Z3 ft/sec.

Heat Transfer to Single Phase Fluids

By dimensional analysis it can be shown that for smooth arinuli

under fully developed conditions

Nu

a(Re)b (p)C (Dz/Dl)d

(39)

Wiegand (1945) analyzed a large amount of data on heat transfer in

annuli and suggested the following relationship.

hDe

for Re >

- 0 023

(DeG 0.8

C0

kb

(2)0. 45

D1

(40)

Properties are evaluated at the bulb temperature.

Monrad and Pelton (1942) recommended the following equation,

which gives results close to equation (40)

17

hD

(-s)

k b

-

02

DeG

p.

b

Cp p.1'3 D20

' k 'b '

(41)

Experimental work by Monrad and Peltori was a more systematic study

of heat transfer in annuli than any- preceding work. Calming sections

were used in the experimental apparatus, and the data obtained in this

manner were only slightly affected by entrance.

Knudsen and Katz (1950) did some experimental work on pressure

drop and heat transfer in smooth and modified annuli. Their heat

transfer results for smooth annuli were in agreement with equation

(40).

Barrow (1955) studied heat transfer in an annulus with a heated

core tube. No calming section before the heated sectionwas used to

ensure a well developed velocity profile before the fluid was heated.

Miller, Byrnes and Benforado (1955) and Stein and Begell (1958)

used spacers to ensure the concentricity of the core tube relative to

the outer tube. The spacers served to break up the velocity and

temperature profiles.

Work on turbulent heat transfer in annuli with small cores has

been done by Mueller (1942), Crookston, Rothfus and Kermode (1968)

and Unzicker (1967).

Several theoretical studies (Deissler and Taylor, 1955;

Knudsen, 1962; Kays and Leung, 1963; Wilson and Medwell, 1968;

Quarmby and Anand, 1969) have been made recently on annular heat

18

transfer. Deissler and Taylor (1955) were possibly the first to

publish analytical work on heat transfer for fully developed turbulent

flow in eccentric annuli. Knudsen (1962) has derived expressions for

j factors for turbulent flow in annuli using Colburn's analogy. His

relationships are:

2/3

f/2

=

02( la)O.2 X-a

0.023 Re

a(1-X

l-X

-

h2

I

Ct2

IP

'C G' '

p

k

= 0.023 Re°

2

1

a)0. 2

1 -x

Experimental data agree with these expressions within

10 percent.

Kays and Leung (1963) have presented analytic solutions for

turbulent heat transfer in annuli with fully developed velocity and

temperature profiles and constant heat rate per unit of length for a

wide range of radius ratios, Reynolds numbers, and Prandtl. numbers.

The solutions are based on empirical velocity and eddy diffusivity

profiles. Their analytic results for Prandt], number of 0. 7 agree with

their experimental data on air for Reynolds numbers >30,000.

Wilson and Medwell (1968) have employed a modification of the

velocity distribution due to Van Driest. Their analytic results for

19

Prandtl numbers of 0. 7 and 1 agree with those of Kays and Leung

except at a radius ratio of 0.2. Above Prandtl number of 1, the

analysis of Wilson and MedweU underpredicts the Nusselt modulus.

Analytic results of Quarmby and Anand (1969) for fully developed

turbulent heat transfer in concentric annuli with uniform wall heat

fluxes cover a range of radius ratios from unity to 50, Reynolds

number from 8000 to 500,000, and Prandtl numbers of 0.01, 0. 7,

1,

10, 1000. They report good agreement with experiment of results for

Prandtl number of 0. 7 over most of this range of variables and

satisfactory agreement with some experiments or a few other Prandtl

numbers. The formulation of their analysis takes into account the

dependence of the turbulent ve'ocity profile on the Reynolds number and

the point of maximum velocity.

Heat Transfer to Liquid-Liquid Dispersions

Finnigan (1958) and Wright (1957) studied heat transfer to

liquid-liquid dispersions flowing in a tube using a petroleum solvent

(Shell solvent) as the dispersed phase and water as continuous phase.

Finnigan correlated his data by the use of a Dittus-Boelter type equat ion

() = 0.023 (DG)0.8 (Pc)O.4

where subscript c refers to the continuous phase. Wright used the

(44)

20

Colburn equation to correlate his data

(cG

k213 = 0.023

(DG)-0.2

(45)

Heat capacity C in equation (45) was the weighted average of the

mixture. There was considerable scatter in the data. Both investi-

gators used the dispersion properties to evaluate the Reynolds number.

Faruqui and Knudsen (1962) measured the velocity and temperature

profiles of unstable liquid-liquid dispersions in vertical turbulent flow

in a tube using Shell solvent as the dispersed phase and water as the

continuous phase. From an analysis of the velocity profile data they

concluded that the dispersions could be treated as Newtonian fluids.

The temperature profiles indicated that the dispersion behaved as a

single phase fluid with a Prandtl number equal to that of the contin-

uous phase at the film temperature. They correlated the heat transfer coefficients with the usual Colburn heat transfer j-factor equation

using the Prandtl number of the continuous phase at the film temperature and the Reynolds number based on effective dispersion viscosity.

Legan and Knudsen (1966) investigated the momentum and heat

transfer characteristics of unstable, liquid-liquid dispers ions flowing

turbulently in a circular tube. Two mineral oils, a Light oil with

viscosity of 15 centipoise, and a heavy oil with viscosity of 200 centi-

poise were used as the dispersed phase with water as the continuous

phase. At Reynolds numbers above 60, 000 the heat transfer

21

coefficients follow the relation

= 0.023 Re°

2

where the Prandtl number is that of the continuous phase evaluated

at the film temperature and the Reynolds number is based upon the

viscosity of the dispersion evaluated at the film temperature. Below

a Reynolds number of 60, 000 individual curves were obtained for each

light oil dispersion and the curves lie much below equation (46). Heat

transfer results for heavy oil agreed reasonably well with equation

(46) over the range of Reynolds numbers investigated. Deviations

occurred at high temperature in case of heavy oil. Legan and Knudsen

suggest that under these conditions either the dispersions do not

behave as Newtonian fluids or that droplet coalescence causes the

dispersion to behave as anon-homogeneous fluid.

Heat Transfer to Non-Newtonian Fluids

Metzner and Friend (1959) have given a correlation for purely

viscous non-Newtonian fluids in turbulent flow in tubes for small

driving temperature difference. It is based on the analogy between

heat and mass transfer in turbulent flow proposed by Reichardt (1957)

and extended to non-Newtonian fluids by Metzner and Friend (1958).

f/Z 9

(St)

irn

1

m

+

m

11.8fT7[(Pr)wb -iJ

1/3

(Pr)wb

-.

22

where the Stanton number is given by h Im ICpG. h Im is the log mean

heat transfer coefficient.

is the ratio of the bulk mean velocity

to the centerline velocity.

0

m

is the ratio of mean to maximum

temperature difference. The Prardtl number (Pr) wb is evaluated at

the shear stress at the wall and at the average bulk temperature of the

fluid.

Petersen and Christiansen (1966) have improved this correlation

considerably and extended its applicability to large temperature

differences by redefining the Pranitl number to be used, and by

introducing a viscosity ratio term of the type proposed by Kreith and

Summerfield (1950). Their equation for pseudoplasticfluids is:

f

'20

St

=

1

,11ww

'1 wb

.

m'

-0. 1

11.8 ,JTZ{(pr)-i]

(48)

+

where the Prandtl number (Pr) is defined as:

p

(Re)

(Pr)

=

(Pr)Wb x

wc

The Reynolds number (at the wall shear stress and the critical flow

rate), (Re), was derived from the stability parameter developed by

Flanks (1963):

(Re)

wc

1, 616

(n+

)

4n+2)(n+l)

(3n+1)

23

The viscosities r ww and ri wb are evaluated at the wall shear stress,

and at the wall temperature and the bulk fluid temperature,

respectively. Equation (48) is only valid for Re > 10, 000.

EXPERIMENTAL PROGRAM

The research described in this report is part of a project being

conducted at this university to study the momentum and heat transfer

characteristics of two phase liquidrliqui.d systems. Previous work has

been confined to the investigations of flow in pipes. The annutus,

being an important industrial geometry, was therefore selected for the

present investigation. It also has some advantage from an experi

mental standpoint. The results reported by Legan and Knudsen (1966)

have indicated a need to study friction factors and heat transfer coef-

ficients to determine the effect of the physical properties of the liquids

on the dispersion, as well, as the effect of temperature. They also

reported that the region of Reynolds number below 50, 000 needed

further study. In addition to these goals, it was desired to develop a

sliding thermocouple to measure the local heat transfer coefficients

and entrance lengths.

Four organic phases were chosen to provide a wide range of

properties (viscosity and interfacial tension): the Shell solvent (with

a viscosity of 1.0 centipoise and interfacial tension (with water as the

second liquid) of 49 dynes 1cm), iso-octyl alcohol (9 centipoise and

12 dynes /cm), and heavy oil (200 centipoise and 48 dynes /cm). The

heavy oil was studied most extensively. A Reynolds number range of

l0-l0 was investigated. A summary of all the experimental runs is

given in Table 1. The following system was used in identifying the

25

runs. The first two letters designate the organic phase: SS for Shell

solvent, 10 for iso-octyl alcohol, LO for light oil, and HO for the

heavy oil. The numbers following the two Letters signify the actual

concentration of the organic phase in volume percent. Thus a run

labeled 1023. 6 would indicate an iso-octyl alcohol dispersion of 23. 6

volume percent.

Table 1. Summary of experimental program.

Dispersed

phase and

concentration

Temperature

range

(°C)

L 025

L04. 6

H032. 5

H014. 1

H07. 5

H02. 1

23-59

Friction

factor

8 flow rates

between 1.5-4

lb/sec and at 3

temperatures

bounding the

temperature

range

At 2 tempera-

1023. 6

SS19. 2

SS4, 7

20-37

SS94.l

20.5

tures in case

of 1023.6 and

Heat

transfer

7 flow rates

between J.5-4

lb/sec at room

temperature.

Readings at

higher tem-

peratures taken

at 4 lb/sec at

intervals of 7°C

SS 19. 2

4 flow rates

3 flow rates

26

EXPERIMENTAL EQUIPMENT

The experimental apparatus is shown schematically in Figure 1.

The organic phase and water were mixed in the stainless supply tank

and were kept in dispersed state through the combined mixing action

of two variable speed mixers and the fluid returning to the tank. The

dispersion was circulated from the tank to the orifice, vertical test

section, heat exchanger and back to the tank. A short flexible rubber

hose was provided at the end of the return line so that the liquid could

be diverted to a weighing tank for measurement of the mass flow rate.

The test section was equipped for pressure drop and heat transfer

measurements. Flow rate through the test section was controlled by

diverting a portion of the dispersion to the tank through the bypass line

provided at the pump. Four different liquids were used as the organic

phases: Shell solvent 345 (a commercial solvent marketed by Shell Oil

Company), Iso-octyl alcohol, Light oil (white oil No. 1), Heavy oil

(white oil No. 15), The last two were the highly refined oils supplied

by Standard Oil of California. The physical properties of these liquids

along with the methods used for their determinations are given in the

Appendix. Thermocouples were provided for measurement of bulk

temperature before and after the test section. Wall temperature of the

inner tube of the test section was measured by a sliding thermocouple.

The test section was connected to the main piping system by four

FLEXIBLE

HOSE

POLYETHYLENE TUBES +

TH

CORE TUBE

MIXERS

PLEXI

GLASS

L. TUBE

SUPPLY

TANK

2

-OP

DRAI N

lxi

P PRESSURE GAUGE

TH THERMOCOUPLE

WATER FLUSH

PRESSURE TAP

-TH

-

PUMP

HEAT EXCHANGER

Figure 1. Schematic flow diagram.

28

polyethylene tubes 1 /2 inch I. D. and 1/6 inch thick, The important

individual components of the system are described below in detail.

Supply Tank and Pump

The 80-gallon, stainless steel supply tank and the pump were the

same as used by Finnigan (1958) and have been described by him in

detail. Two propellor-type agitators with variable speed drive were

provided to ensure complete mixing of the dispersion. The bronze

turbine pump was driven by a three horse power electric motor, A

pressure gauge on the discharge side of the pump indicated the pump

discharge pressure. In order to prevent leakage of air into the system,

this pressure was always maintained above 15 psig by partially closing

the valve (valve number 4 in Figure 1) at the end of the return line,

Piping System

To avoid corrosion problems, the materials in contact with the

dispersion were only stainless steel, copper, brass, plexiglass,

polyethylene, or rubber. All the piping system, except the test section and its connecting tubes, was constructed of standard 2-inch and

1-1/4 inch brass pipe, and a section of flexible synthetic rubber hose.

The 2-inch pipe was located on the suction side ofthe pump. A 2-inch

gate valve was inserted in this line so that the piping system could be

drained independently of the tank. Flexible hose was a 2-1/2 foot

29

length of heavy wall synthetic rubber located at the efflux point of the

system. This rubber material was found to be resistant to alL of the

liquids used in this investigation. A number of unions were used for

ease in assembly and dis-assembly. Provision for drainage was made

at the low point of the system. The entire system was washed with a

water solution of sodium tripolyphosphate and then several times with

water.

A 20-gallon stainless steel weighing tank was placed on a

calibrated platform scale close to and approximately at the same height

as the supply tank. The flow rate was measured by diverting the flow

stream from supply tank to the weigh tank by means of the flexible

hose and noting the time required to collect a known weight1 101.2

lbs of the liquid.

Test Section

The outer tube of the vertical annular test section shown in

Figure 2 was made out of two pieces of 1.239 ± .004 inch I. D.

plexiglass pipe. The two pieces were provided wtth a flange at each

end and then joined together with bolts. The flanges were fixed with

weld-on No. 3 acrylic adhesive. Gaskets in all the flanged connections

were made out of Vellumoid sheet packing. This material supplied by

the Vellumoid Company, Worcester, Mass., is good for oil, gasoline

and water service. The inner core tube was made out of 1 /2 inch

30

TENSION

BOLTS

'SI

1/4"

BRASS

FLANGE

1/4"

,

3/8"

,,

:

__, ,,,,..,

PLEXIGLASS

FLANGE

is"

.1/2"

FLUID

j

COPPER TUBE

PRESSURE

PLEXIGLASS

TAP

39 1/8'

INLET

4,1/4" BRASS PIPES

IiU

1/2"

TUB E

PLEXIGLASS

FLANGE

1/2"

STAINLESS STEEL

PRESSURE

TAP

r2W

?,.vwt

TUBE

uI

FLUID

9 1/8"

WflflJfltflflflfltffflflfl. OUTLET

4 1/4" BRASS PIPES

PLEX IGLASS

FLANGE

3/8"

3/8"

1/4"

BRASS FLANGE

3 3/8"

DIA

COPPER TUBE

Figure 2. Detail of test section.

31

stainless steel tube with 1/2 inch coppertubes at the ends. The

0. 508 ± 0. 002 inch 0. D, stainless steel tube was 39. 12 inches long

with 0.010-inch wall thickness. The copper tubes of the same 0. D. as

the stainless steel tube having a wall thickness of 0. 065 inch served as

conductors (leads) for the electric current and also ensured fully

developed flow in the test section. The upper copper tube was 39-1/8

inches long and the lower one 9-1/8 inches. These tubes were joined

to the stainless steel tube with silver solder and then machined to

ensure uniformity of diameter, The lower copper tube had a brass

flange 1/4 inch thick and 3-3/8 inch diameter welded to it 1-1/4 inch

from the lower end. This flange was bolted to the lowest flange of the

outer plexiglass pipe to close the lower end of the annular test section.

An 0 ring arrangement was used to close the upper end. This is shown

in Figure 2, To make the test piece concentric it was found necessary

to stretch the inner core. As shown in Figure 2, a brass flange,

1 /4

inch thick with four threaded holes, was soldered to the upper copper

tube. Tightening of the bolts through the holes provided the necessary

tens ion.

Two 1/4 inch pipe taps facing the copper-stainless steel joints

were drilled and threaded 39. 12 inches apart in the outer tube, thus

defining the length of the test section for pressure drop measurements.

Because of the silver in the joints, the length of the test section for

heat transfer was only 38, 170 inches. Heat generated in the copper

32

tubes was 0. 5% of the total energy input. The dispersion entered and

left the annular section of the test piece through four polyethylene

tubes, 1 /2 inch I. D. and 1/16 inch thick, arranged equidistant around

the circumference. This ensured uniform flow conditions at the

entrance and exit. Four 1/4 inch pipe taps, equally spaced around the

circumference, were drilled into the outer tube at each end. Pieces

of 1/4 inch brass pipe threaded at one end were fixed into these taps

and polyethylene tubes were clamped on. The other end of the poly-

ethylene tube was connected to the 1-1/4 inch brass pipe as shown in

Figures 1 and 2. This arrangement provided a flow entry section of

length 35-i /8 inches (or 49 diameters) at the top and a calming section

of length 6-1/2 inches (9 diameters) at the bottom.

In order to measure heat transfer coefficients, heat was generated in the stainless steel tube by passing direct current through the

core. The power was supplied by a rectifier with 220 V A0 C0 input

and a rated D. C. output of 28 volts at 1000 amps. The electrical

connections between the rectifier and the core tube were made with

copper cable 1 /2 inch diameter, A resistance (a piece of stainless

steel tube) was placed in series to vary the energy input in the test

section0 The resistance could be varied by connecting the cable on the

tube at different positions. This vertical stainless steel tube was

supported by insulated clamps and cooled by passing water through it

to dissipate the heat generated.

33

The inlet and outlet bulk temperature of the dispersion and the

wall temperature of the stainless steel tube in the test section were

measured with copper-constantan thermocouples. All the thermocouples were made from the matched spools of number 30 B & S

gauge wire supplied by the Leeds & Northrup Company. Voltages

generated by these thermocouples were checked at 0°C, 100°C and

were found to agree closely with the values supplied by Leeds &

Northrup Company. The thermocouple wire was held approximately

in the center of a 1/4 inch copper tube 5 inches long with the help of

Hysol 1 C white epoxy, supplied by Hysol Division of Dexter Corporation. The epoxy was found to be highly resistant to the fluids under

investigation. The thermocouple bead projected outside the epoxy on

one side of the tube and the thermocouple wires coming out on the

other side were lead to a potentiometer. The thermocouple was

checked to make certain it was insulated from the tubing. The 1/4

inch copper tubes carrying the thermocouple were installed with

standard fittings into the 1-1/4 inch brass pipe with thermocouple bead

meeting the fluid in the center of the stream.

Temperature Probe

A temperature probe was specially constructed to measure the

inside wall temperature of the stainless steel tube. The thermocouple

in this probe was held in a copper piece that was in contact with the

34

inside of the stainless steel tube. The arrangement is shown in

Figure 3. The side of the copper piece in contact with the stainless

steel tube was machined to match its curvature with that of the tube

wall. The thermocouple bead was inserted in the small hole, drilled in

copper piece and the hole closed by pressing the piece followed by

application of Devcon epoxy resin. The copper was held in a cylin-

drical plexiglass piece with a spring underneath. The action of the

spring ensured contact of the copper with the stainless steel tube.

Thermocouple wires came out of a hole 3/32 inch diameter drilled in

the plexiglass piece. In another hole 1/8 inch diameter, one end of a

stainless steel rod 4-1/4 feet long was fixed with Devcon epoxy to

facilitate the movement of the thermocouple up and down and along the

circumference of the stainless steel tube from outside the test piece.

The thermocouple wires were wound along this rod to avoid the

possibility of damage to the wires by their getirig trapped or dragged.

As the outside diameter of the plexiglass piece was greater than the

inside diameter of the copper tube, the temperature probe was inserted

into the stainless steel tube before silver soldering the lower copper

tube to the stainless steel tube.

All the thermocouples were connected through a multi-position

selector switch to a Leeds & Northrup (No. 737621) potentiometer.

The cold junctions of the thermocouples were inserted in a thin glass

tube filled with oil and the glass tube was immersed in a bath of

r

A

THERMOCOUPLE

H7/64-

0477"

DIA

I

WIRES

r

/

COPPER

PIECE

3/32" DIA

PLEXIGLASS

STAINLESS

STEEL

TUBE

7/I,J/3 24

11/16"

I"

I

I/8"DIA

STAIN LESS

STEEL ROD

Figure 3. Temperature probe.

SECTION AT AA

36

crushed ice to maintain a constant temperature of

O°C

The voltage across the core was measured by a Simpson 270

VOM meter. A DB-1Z G.E. ammeter was employed to measure the

current flowing through the core. A 1200 amp 50 my shunt was placed

in series with the circuit after the core and the ammeter connected

across it.

The pressure drop across the test section was measured with a

five-foot long U-tube manometer filled with carbon tetrachioride under

water. A thermometer installed on the manometer board indicated the

ambient temperature. The threaded taps on the outer tube of the test

section were connected to the manometer through 1/4 inch tube fittings

and Crescent precision instrument 0. 25-inch 0 D. PVC tubing. Water

was used as the pressure transmitting fluid. The lines were horizontal for a distance of about five feet at each pressure tap to prevent

the dispersion from getting into the vertical portion of the tubing due

to the movement of the manometer columns. Water connections,

shown in Figure 1, were provided for flushing.

37

EXPERIMENTAL PROCEDURE

A run was started by charging a weighed amount of continuous

phase to the supply tank and allowing this to circulate for a few

minutes through the entire piping system. The manometers were

flushed with water to remove any entrained air or organic phase.

Care was taken to ensure that the return hose was mairitained under

the liquid level at all times. The power to the inner core of the test

section and the cooling water to the heat exchanger were turned on.

Cooling water was adjusted to attain constant bulk temperature of the

fluid entering the test section. It took about 15 minutes to attain

equilibrium with water. The required amount of dispersed phase was

then added to the supply tank and allowed to mix through the combined

action of pump, stirrer and the fluid returning to the tank. The mixing

was continued until the equilibrium was attained as evidenced by no

change in pressure drop and temperature readings. This required two

to three hours.

When a uniform dispersion had been obtained heat transfer data

were obtained. The thermocouple readings of wall temperatures and

inlet, outlet bulk temperatures, volts across the inner core, current

flowing, and the flow rate were recorded. The flow rate was mea

sured by diverting the flow to the weighing tank noting the time to

collect a known weight, usually 101.2 pounds of the liquid. Flow rate

38

was then adjusted and further heat transfer data taken. Wall temperature was studied in detail for one flow rate (usually 4 Ib/sec) to obtain

the entrance length. At other flow rates wall temperatures in the fully

developed region (from X = 50. 5 to 74, 5 cm) only were recorded. To

avoid problems of axial conduction from the stainless steel tube to

the copper tube of the core, the power input to the core was reduced

at low flow rates to keep the difference between wall and bulk temperature below 20°C. The reduction in power was achieved by connecting

another resistance (stainless steel tube) in series with the circuit and

dissipating the heat with cooling water.

After completing the heat transfer data at room temperature, the

flow rate was raised to its maximum value, and the manometers were

flushed with water. Power was discontinued and cooling water adjusted

for isothermal conditions in the test section. The temperature of the

dispersion was kept within 0. 5°F. Pressure drop data were then

taken at several flow rates. Manometer deflection across the test

section, temperature of the manometer board and the flow rate were

recorded.

At this point the flow was again increased to its maximum value

and power was applied to raise the temperature of the emulsion. Heat

transfer data were taken at this flow rate under steady state conditions

after each increase of about 7°C in the bulk temperature. Pressure

drop data were taken at several flow rates at the highest temperature

39

and one intermediate temperature. The highest temperature was

usually 370C for systems containing Shell solvent or iso-.octyl alcohol

and 59°C for systems containing light oil or heavy oil. For pressure

drop data at the highest temperature, the temperature variation of the

mixture was maintained within ± 1°F by adjusting the amount of heating

time. After the dispersion was heated to the desired temperature a

few minutes were allowed to pass before the manometer readings were

taken.

A one-liter sample was taken from the return line at least twice

during a series of runs for each dispersion. The samples were sea.led

and allowed to separate overnight so that the composition of the

dispersion could be obtained. The deviation of composition from the

average concentration is given in the Appendix. To obtain a clear

separation of the heavy oil dispersions the samples had to be heated

to about 75°C. Before the next run the system was thoroughly flushed

several times with water and drained. When changing from heavy oil

to light oil and from light oil to iso-octyl alcohol, the system was

rinsed with Shell solvent and then flushed with water. Before switching

over to 100% Shell solvent or dispersions with Shell solvent as con-

tinuous phase, the system was completely drained, rinsed with Shell

solvent and again drained.

The observed and calculated data are given in the Appendix.

40

SAMPLE CALCULATIONS AND ERROR ANALYSIS

Pressure Drop and Friction Factor

The pressure drop across the test section,

T'

was ca1cu-

lated from the manometer deflection, HT, and the effective density of

the manometer fluid, p

by the expression

-.

T

= K(HT)(p)

(51)

where K converts HT from inches to feet. Since the test section was

vertical with liquids of different densities in the pressure transmissiori lines and the test section, part of the pressure drop,

P,,, was

If the length of the test

due to the static pressure difference,

section is L, the density of the liquid in the test section is p and the

density of the pressure transmission liquid (water) is p, then

PS

KL(p-p)

(52)

Since in this case dispersions were flowing in the test section,

was

the density of the organic phase and water comprising the dispersion.

Pf was then

The friction loss,

Pf

+

=

K(HT)(p) + KL(p

"wy

(53)

The friction factor is calculated by

gD

c

;

ZpVL

(_Pf)

e

The outer wall friction factor, f2, is given by

(54)

41

-

(R

f

R

m

2

R2)g(-Pf)

(55)

2

=

R2PeV L

is calculated by Clump's (1968) equation

R

m

= R +{(

R-R

2

2

1

1

(1.08 (R1/R2)3

2.Z0(R1/R

)Z

+ 1.65 (R1/R2) + 0.48)1

-

RRR-

Let

then

R2)

RD

2

e

-

(57)

(RRR) £

=

Since the velocity, V. is related to the mass flow rate, W, by

V = W/Ace

p

(58)

- D)

(59)

and

A

=

(71

/4) (D

Thus

De A2

e

2WL

2

Given

= 0.508 inches, D2 = 1.239 inches,

L = 39. 12 inches and R2 = D2/2, R1 = D1/2,

De =D2 -D

then

R

= 0. 411 inch, RRR

0. 948, A = 0.00696 It2,

(60)

42

and

Pf - -j{HTp

f

R

e

Re2

) + 39.12

(61)

e

=

1.458 (10)(- Pf) Pe/W

(62)

=

0. 948 1

(63)

DW

e

(10)

=

Ai

ce

2 (R2 - R2 ) W

2

m

= AR

2

c

=

(16)

e

(RRR) (Re)

The relationship suggested by Rothfus and coworkers was used for

evaluation of effective viscosity

1

- 0. 4

=

4. 0 log (Re2

=

4. 0 log (RRR x Re x

=

4. 0 log (RRR x

- (0. 4 + 4. 0 log

De:

(15)

0. 4

x

f2)

)

(64)

The pressure drop, friction factor, Reynolds number, and the

dispersion viscosity were calculated and analyzed with the aid of a

CDC 3300 digital computer. The program performed a least square

analysis to find m and b in the equation

DW

e

=

m

log

(RRR

x

x..112)+b

1/"./

A

(65)

43

The slope m was then fixed at 4.0 (assuming Rothfus and coworkers'

equation) and a new intercept was obtained by a second least square

analysis. This value was then used for the calculation of an effective

viscosity for the dispersion.

=

10

-(b + 0.4)/4.0

(66)

A least square analysis of run HOZ. 1 (23. 3) gave an effective

lb/ft sec. A sample calculation for this run

viscosity of 6.38 x

showing the use of equations (61), 62), (63), (10), and (16) is given

below.

Given: HT = 32.46 in C Cl4

W = 4.04 lb/sec

Temperature of dispersion

23.

Ambient temperatire = 27. 7°C

62.28 lb/ft3

Density of heavy oil at 23. 2°C

pm

54.06 lb/ft3

=36.52

therefore,

=

(0.21)(54.06) + (.979)(62.28) = 62.11 lb/ft3

-Pf = -j[(32. 46) (36. 52) + 39. 12(6. 11 -62.28)]

-

P

= 98,23 lb/ft3

f

=

1.458 (10

f

=

.00544

) (98. 23) (62. 11) / (4.04)2

44

f2

=

.948 (.00544)

=

.00515

(.731 /12) (4. 04) / [(.00697) (.000638)

Re

Re

= 55400

Re2

=

II

0. 948 (55400) = 52500

Heat Transfer

The heat transfer coefficient, h, was obtained from the expression

q = hALT

(67)

T is the temperature difference between the wall and the fluid.

where

A=

A

(0. 508/12) (96. 95/30. 48)

D Lh

0. 4203 ft2

where Lh is the heated length, 96. 95 cm. The he3t transferred,

is

calculated by

RSS

q = 3,4129 VC RSS+RCU

(68)

where C is the current, and V is the voltage across the inner core.

Factor 3. 4129 converts watts into Btu/hr. The term RSS /(RSS + RCU)

corrects for the losses in copper leads. RSS is the resistance o the

stainless steel core in the test section and RCU is the resistance of the

copper tubes on the two sides of the stainless steel core

RSS = .0732, RCU

RSS

RSS + RCU

995

.00344

45

A check on the energy balance can be made by the following

express ion:

q = 3600 w C (TBZ - TB1)

The Stanton number was calculated from

St=

h

p

where C is that of the continuous phase.

p

The sliding thermocouple measured the wall temperature, TWI,

on the inside of the core tube. For evaluation of the heat transfer

coefficient, the wall temperature on the outside of the core tube must

be known. The relationship between these two temperatures has been

derived in the Appendix and is

TWO

TWI

q III

Zkss

(r0/2 - r. 2/2 - r. 2In r 0 /r.)

(71)

1

L

The heat generated per unit volume of the core, q", is calculated by

qW

=

2,

lr{r 2 - r.j Lh=

=

.000346 ft

= q/v

254'l2)

(72)

2

244"2) 2-9695

30:48

(73)

then

= TWO-TB

TB = TB1 + (TBZ - TB1) X/96. 95

(75)

where X represents the Iength in cm of the test piece up to the point

where TB is required, with zero length corresponding to the point

46

where heat transfer begins. The total length of the heated core is

96.95 cm.

The Prandtl number used was that of the continuous phase at the

bulk temperature. The Reynolds number was calculated by equation

The effective viscosity at the bulk temperature was obtained

(10).

from the isothermal pressure drop data assuming that the logarithm of

the viscosity (lb/ft sec) versus the logarithm of the absolute tempera-

ture (R°) is a straight line.

Monrad and Pelton's equation was used for correlation of heat

transfer data.

D

oz (-)

Re

(St)(Pr)213

=

.

(St)(Pr)2' 3

=

.031971 Re

-.2

or

-.2

(76)

An example showing the numerical calculation of the heat

transfer coefficient, the Stanton number, and the Reynolds number is

given below. The dispersion considered is L04. 6. The observed

data were: W = 3.92 lb/sec, TB1 = 42. 1°C, TB2 = 43. 0°C, TWI =

54. 7°C at X = 62.5 cm, C = 292 amperes, V = 22.8 volts.

(3.41) (22.8) (292) (.995)

q

q = 22600 Btu/hr

r

=

0.508 / (2 x 12), r. = 0.488 / (2 x 12)

From equation (71), TWI - TWO

2. 43°F

1.4°C

47

TWO = 54.7 - 1.4 = 53.3°C

TB

=

42, 1 + (43.0 - 42. 1) (62,5) I (96. 95)

=

42.7°C

53,3 - 42.7

10. 6°C

= 22600 / (0. 423 x 1.8 x 10.6)

h

= 2790 Btu/hrft2 °F

hA C

h

St

GC

-

3600CW

p

(2790) (.00697)

(3600) (3.92) (1,0)

=

p

.00137

The viscosity and thermal conductivity of water were obtained

from Perry (1950). For water, C = 1. Prandtl number of water at

42. 7°C is 4. 13.

(St) (Pr)213

(.00137) (4.13)2/3

=

.00353

To calculate the Reynolds number the dispersion viscosity at the bulk

temperature (42. 7°C) is required. To approximate this viscosity

pressure drop data were taken at three bulk dispersion temperatures:

26. 1, 42.2, and 59. 0°C. The viscosity at these temperatures of the

dispersion was found by the previously discussed method to be

.000716,

.

000567, and .000448 lb/ft sec, respectively. Assuming that

the logarithm of the viscosity in lb/ft sec versus the logarithm of the

absolute temperature (°R) is a straight line, the viscosity of run

48

L04. 6 as a function of temperature is

9. 193 - 4,517 Log (°R)

Log

Using this equation

at 42.7°C = .000562 lb/ft sec

and

=

(.731/12) (3. 92) / (.00696 x .000562)

Re = 61,100

and

.032

Re2

.00353 comparedwith (St)(Pr)2'3 of .00354.

=

Analysis of Experimental Errors

The experimental errors can be estimated by taking the differentials of the quantities involved. The error in friction factor is

estimated by taking the differential of equation (60)

g(D2 - D1)

2

(D

D)2

-

f

P1)

e

(60)

32W2 L

e

(D2 - D1)3 (D2 + D1)2 (- Pf)

32 W2 L

There is negligible error involved in measuring L since it is a

large quantity, Then

df

dp

e+

d(D-D)

D2-D1

[

'

dD1

'dD+

1

d(D-D1)

dD2

'dD]

2

49

+

dD1

D2+D1

d(-z. Pf)

-Pf

+

dD1+ dD2

dD2]

dW

-

dD1

dPe

df

d(D2+D1)

d(D2+D1)

2

-

+

dD1

dD2

+

=

dD2

+ZD+D +

Error in

d(Pf)

-Pf

2

aw

results from the error in composition f the dispersion and

the density of the organic phase. It is of the order of ± 0.2 percent.

D2-D1

D2-D1

dD2

D2+D

- .006 or ± 0,6 percent

-

dD1

D2+D1

- .003 or ± 0.3 percent

-

-

(A)

.VVL

1.747

.001 or - 0. 1 percent

0.004 - .002 or ± 0.2 percent

1.747

100

- D2D1)dDz

D2+D1

=

± 1.2 percent

The error in manometer readings was approximately ± 0. 5 percent

and hence a maximum error of

±

0. 5 percent in - Pf . The error in

the total weight of the fluid was negligible since it was estimated

50

accurately by measuring the volume of water and temperature and the

same weight was used in each run. Assuming an error in time of 0. 1

0.1 x 100 percent or 0. 4 percent.

sec, the error in W is ---x 100

=

± (0.2 + 3 x 0.3 + 1.2 + 2 x 0.1 + 0.5 + 2 x 0.4)

=

± 3.8 percent

The error in calculating f is of the order of ± 3. 8 percent.

R2-R2m

2

R2(R2-R1)

2(R2-R2

2

m

RRR

RD

2

e

dR

ZR2

d(RRR) -

R2(R2-R1)

dR

ZRm dR

+{

dRm

dR1

(R-R2)

ZRm dR2

- 1 +{(

R-R

2

22

(R2Rm) (R2,

+

(R2(R2R1))2

l/2(l.08(R1/R2)3

+ 1. 65(R1 /R2) + 0.48)11

0.68

dR

1

1) (3,24(R1/R2)3 /R1-4.4(R1/R2)2 /R1

+ 1.65 1R2)

=

d R2

[R2(R2-R1)]

m

R2(R2-R1)

(2R2-R1)

-

2.20(R1/R2)2

51

2

::

1)

[-3. 24(R1 /R2)3 / R2+4. 4(R1 /R2)2

/R211 + i/2[1.08(R1/

-

-

3

)

2.20(R1/R2)2 + 1.65(R1/R2) + 0.48 1

0.38

= 0.411

RRR = 0.948

d(RRR) = -. 042 dR2 + 0. 106 dR1

d(RRR)

RRR

- -.044dR2+.1l19dR1

d(RRR) x 100

RRR

cm1 = .001

.002

dR2

=

± (.0088 + .0112) percent

=

± .02percent

The error in RRR is negligible. The error in f2 is of the order of

3.8 percent. The error in effective viscosity is estimated by taking

the differential of equation (64)

i/'f

DW

=

4.0 log (RRR x

x

- (0.4 + 4log)

(64)

or

DW

=

(RRR)(

From equations (60) and (63)

exp[-2

303 ((1/2 + 0.4)1

(77)

52

(RRR) g(D-D1) 2(D-D)

2

Pf)

32W2L

Substitution for A.

c

=

c

,

f

2

, De in (77) results in

(RRR)

3/2

exp[- 2.303

(D2-D1)

- 1/2

(f2

3/2

+0.4)1

Error in RRRI L is negligible

d

e

d(D2-D1)

3

-

d

+

2

2.303 -3/2

+

8

1e

+

1

2

d(- Pf)

-

Pf

df2

All the right hand side terms except the last one have been evaluated

already. They are

dD2

d D1

-

D2D1

D2-D1

=

±0.009

d(D2-D1)

D2-D1

d

= 0.002

d(-

-

Pf)

Pf

The last term is

0. 005

- ± (0.006 + 0.003)

53

f2dfa

1/a x error in f2

fl/a

___

a

f2 -

=

0. 038

f' /2

Setting f2 = . 00469 (minimum value of f2) results in an estimate of

maximum error. This maximum error is

(2. 303) (.038) (004)l/'Z

d

e

± [(3/2) (.009) + (1/2) (.002) + 1/2 (.005) +

=

is of the order of 19 percent.

DW

e

-

Ac

d(Re)

Re -

. 161

±.19

The error in

Re

.16

e

4W

-

dW

(D2+D1)

d(D2+D1)

e

dLe

W

dD1

dD2

-

W-

=

±

=

± .20

dPe

-

(.004 + .002 + .001 + . 19)

The error in Reynolds number is of the order of ± 20 percenL

Monrad and Pelton's equation for heat transfer is

(St)

(Pr)2/3

=

.oz (D2/D1)

.53 Re -.2

1

54

Error in .02 (ID2 /D1Y

Re

2

is

d(D2 ID )

D21D1

- (1/5)[ W d(D2 'ID1)

d(D7 ID.1)

d(D2/D1)

D1+

dD 1

=

dL

d(D2+D1)

dID2

dID2

d D2

(D2/D12) d D1 +

-

D

1

dD1

d(D2/D1)

D21D1

-

dID2

-

ID2

Error in .02 (D2/D1Y

Re

=-.53

+ .2

dID

2

1+53

dID1

=( D2+ID1 -

+ .2

D2

D2+ID1

+ .2

-.2+.2

dD2

W

dLe

.53 d ID1 +

dID2

=

dID2

ID1

.2

=

is

dID2

ID2

-

.2 dW

--

due

± (.002 + .002 + .001 + .001 + .038)

. 044 or 4. 4 percent

55

22

h(D-D)ir

hA

St

= h/GC

q

=

=

4WC

RSS

3. 4129 VC

RSS + RCU

The errors in reading voltage and current were 0.5 and 1.0 percent

respectively. Assuming negligible error in the ratio of resistances,

the error in q was therefore of the order of 1. 5 percent.

h = q / (A x

A= 1TD1L

Error in

and hence in A is ± 0. 4 percent.

TWI - TWO

q II?

2k

(r

2

2

/2

r.

/2

r.

in r0 /r.)

o

2

1

i.

Assume an error of 5 percent in the expression on the right hand side.

Because of its small magnitude, it contributes at the most an error of

0. 5 percent in TWO. The errors in reading thermocouples were

of

the order of ± . 025°C.

TWO-TB

tT is of the order of 10-15°C.

Error in thermocouple readings TWI and TB results in an error

of

.025+.025 x 100 or 0.5 percent in AT

10

Total error in

T

0.5 + 0. 5

the test section has negligible effect on h.

1 percent

Heat Loss from

56

Error in h = ± (1.5 + 0.4 + 1)

2. 9 percent

22

q

LxT

-

St

d(St)

St

22

d(St)

St

2

q

d(D2-D1)

2

4WC

d(DD)

4a+

d(D-D) =

2

(D2-D1)

dD1

d(tT)

W

2

(2D2) d ID2 - (2D1) d ID1

2dD2-

2

2D1

2

2dD1

D2-D1

ZD

q

p

ID2

2D2

=

iT

2D

2

1

dD2-(-j5--+

D2-D2

2

d(LT)

1

1

2

D2-D1

1.

dW

W

± (.0150 + .008 + .006 + .01 + .004)

= ±.043

The Prandtl number itsed is that of water and does not involve

any experimental measurements.

The error in St and henze in St Pr2

percent.

is of the order of 4, 3

57

DISCUSSION OF RESULTS

Friction Factor Data

To test the validity of the system and the experimental method,

friction factor data were obtained for water, The results are shown

in Figure 4. Also shown are the upper and lower limits of the data of

Brighten and Jones (1964). The present data fall well within resuLts

of these workers. Therefore, It was concluded that the apparatus, as

well as the experimental technique, were satisfactory. A plot of

versus Re2 for the data on water and Shell solvent is shown in Figure

5.

The results are in good agreement with equation (15), proposed by

Rothfus and coworkers (1955). This equation was used for the least

square analysis of friction factor data and evaluation of efective

viscosity of dispersions, as discussed in the previous chapter. The

Reynolds number was based on the effective viscosity. The observed

and calculated data are given in the Appendix.

The progress of mixing in the circulation system as a function of

time following the addition of a second liquid phase to the system can

be observed in Figure 6. The second liquid phase in this case was

25 percent by volume light oil. Pressure drop (manometer reading)

and heat transfer coefficient are plotted as a function of time witk zero

time being the instant that a second liquid phase is added to the agL

tated tank. Total mass flow rate through the test section remained

58

1

0

t

I

I

EXPERIMENTAL

0087 Re025

200

0079R1°25

100

m

80

- p_ - - -

0

X6.O

-

.-9 OIy

40

I

0'8 I0

20

40

I

I

60 80 100

Re X104

Figure 4. Friction factor plot for water.

WATER

N

V

SOLVENT

0

SOLVENT(NE W)

0

SS941 DISPERSION

I

401o9(Re2.Jç)-O4

oo

I

&

2

4

I

I

I

6

8

(0

Re2 X IO

Figure 5

Outer wall friction factor plot for water, solvent and SS94. 1 dispersion.

38

U)

PRESSURE DROP

36

w

3:

z

C-)

(;34

z

w

28

cr32

I-

000

Iii

0

3O

0

0

0