DONG Energy Power plans and experience in Biomass By Jesper Staal

advertisement

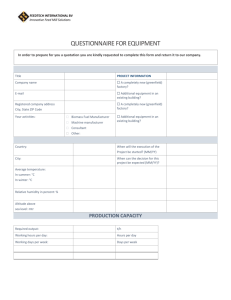

DONG Energy Power plans and experience in Biomass By Jesper Staal Technical Concept Manager Dong Energy Power Asset Development DONG Energy Power The Power business area generates and sells electricity and heat. The CHP plants in Denmark are its core activity. In 2010, thermal electricity generated by Power in Denmark accounted for 53% of total thermal electricity generation in Denmark. Heat generation accounted for 36% of total heat generation in Denmark, equivalent to the consumption of more than 800,000 households in Denmark. Electricity generation, thermal 15.3 TWh Heat generation 53.2 PJ Geographical overview 3 Production capacity Denmark Frederikshavn MW Large power plants Central power plants net capacity Asnæs Power Plant Avedøre Power Plant Kyndby Power Plant Studstrup Power Plant Ensted Power Plant Stigsnæs Power Plant Skærbæk Power Plant Esbjerg Power Plant H.C.Ørsted Power Plant Svanemølle Power Plant 1,057 810 734 700 626 409 392 378 185 81 Small-scale CHP plants Waste-to-energy plants Biomass 10 – 100% Måbjerg Grenaa Herning Studstrup power plant DTU Horsens Small-scale CHP plants Waste-to-energy plants Kyndby power plant 216 94 Esbjerg power plant Asnæs power plant Skærbæk Vejen power plant 5.682 Haderslev (1. January 2008) Ensted power plant Ringsted Haslev Stigsnæs power plant Masnedø Maribo-Sakskøbing 4 H.C. Ørsted Avedøre power plant power plant Slagelse Odense Total installed net capacity Svanemølle power plant Køge Biomass use in DONG Energy 1993 – heat producers are imposed to increase use of biomass 1997 – it becomes possible for biomass usage in former natural gas areas enabling growth of decentralised CHP 2000 –Decision on building straw boiler and wood pellet fired CHP on Avedøre and refurbishment of Herning CHP Straw DONG Energy units Herning Enstedværket Studstrupværket Måbjerg Grenå Avedøre 2 Masnedø Maribo Sakskøbing Haslev Slagelse DONG Energy total Wood pellets tons Wood chips 200.000 30.000 120.000 100.000 51.000 65.000 170.000 42.000 40.000 24.000 24.000 636.000 19.000 300.000 10.000 300.000 5 259.000 Biomass conversion in three steps wood pellets, mill tons Consumption of wood pellets, central plants Plant 3 350.000 T 1,8 mill tons in total Plant 2 750.000 T 1,45 mill tons in total Plant 1. 400.000 T 700.000 T in total Step 1 2014 Step 2 Beginning 2015 Step 3 End 2015 In total the biomass conversion will bring DONG Energy's total consumption of biomass up to 2.7 mill t/year 6 Technical issues related to conversion of AVV1 and SSV3 Issues at AVV1 and SSV3 Boxer fired boilers, high specific firing chamber load ¾ high unburnt levels MPS roller mills ¾ Is milling capacity sufficient? ¾ Alternatives: hammer mills and disc mills Test of milling capacity at MPS mills and CFD calculations of unburnt needed Modify the MPS mill ¾ Double wall has to be built in ¾ The chute has to be extended to get closer to the grinding table ¾ Explosion suppression system has to be applied ¾ Erect wood pellets storage and conveying system to the MPS mill CFD calculations to determine the unburned level ¾ Build a fluid dynamic model of the boiler ¾ With input of wood size distribution from the mill test, calculate the unburnt boiler output 7 MPS mill 40 at SSV3 8 Findings at the milling test and CFD calculations weight-% < 1mm Unburnt (CFD) SSV3 40% load 86,7 SSV3 60% load 83,3 SSV3 80% load 83,0 SSV3 100% load 77,6(82expected) 1,8 % SSV3 wood pellets 70,1 AVV2 100% load 87,0 1,4 % AVV2 wood 73,0 pellets Low load: same milling capacity on MPS as achieved on AVV2 with Loesche mills High load: less milling capacity on MPS as achieved on AVV2, due to overload of the classifier at 90% load 9 Experience from Avedøre plant AVV2 Plant data Tangential fired tower boiler 800 MW thermal Design parameters 300 bar/580°C 16 burners in 4 levels Wood pellets/gas/oil – steam temperature 540°C Loesche coal mills for wood pellets milling HD SCR, Elektro precipitator and wet DeSOx 2001: Commissioning 2005: Coal ash dosing in burner level 3 2006: Steam temp. increased from 540 to 560°C 10 1/5 Experience From Avedøreværket AVV2 2/3 100.000 Woodpellets storage • Automatic working storage • Commissioned in 2010 11 Experience from Avedøre plant AVV2 Handling of wood pellets on covered belt conveyors 3/5 Experience from Avedøre plant AVV2 Milling and burn-out 4/5 Loesche mills used for wood pellets milling Milling table: operation > 300.000 tons wood pellets High availability Most frequent stop due to contaminants in the pellets or worn-out dust pipes Milling 10 kWh/ton Burners Modified coal burner CO-level fluctuate but typical <100 mg/Nm3 Effective burn-out 1,4 % on energy basis eq. to carbon in fly ash at 6-7% DeNOx No significant degradation of the catalyst, due to dosing of coal fly ash 13 Experience from Avedøre plant AVV2 Coal ash dosing and electro precipitator operation SO2 70 NH3 HCl 9 Ingen kulaske 8 60 7 50 6 40 5 30 4 3 20 2 10 1 0 06‐12‐10 00:00 ‐10 0 06‐12‐10 12:00 07‐12‐10 00:00 07‐12‐10 12:00 08‐12‐10 00:00 ‐1 14 HCl & NH3 emission (mg/Nm3, våd) When dosing fly ash the alkali metals (potassium) are fixed in the fly ash Chlorine and sulphur are released to the gas faze Forming of chlorine deposits is minimized; limits high temp. corrosion Forming of submicron alkali-particles is minimized; extends catalysts lifetime SO2 emission (mg/Nm3, våd) 5/5 Thank you for your attention! 15