Oscilloscope Measurements Exercise ENGINEERING-43 Lab-11 – ENGR-43, Lab-11

advertisement

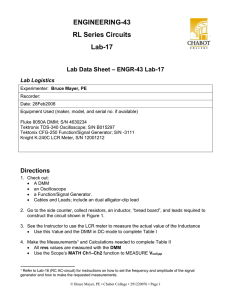

ENGINEERING-43 Oscilloscope Measurements Exercise Lab-11 Lab Data Sheet – ENGR-43, Lab-11 Lab Logistics Experimenter: Recorder: Date: Equipment Used (maker, model, and serial no. if available) Part-1 Directions 1. Check out one each of DMM TEK TDS340 oscilloscope TEK CFG250 Function/Signal Generator (SG) 2. Go to the lead Racks and Find a CoAxial Cable with BNC Connectors (see Appendix 2) on each end a set of probe Leads for the DMM 3. Review Briefly Figure 1 which Shows the control panel for the CFG250 4. With the Scope and SG turned-OFF set the CFG250 Controls as Described in Appendix 1. If you have any questions, ask the instructor. 5. Use the BNC cable to connect the SG-Output to the Scope-Input. Referring to Figure 2: [SG MAIN Output connection]→[Scope CH1 Input Connection] 6. With the CFG250 Power buttons in the OFF Position (Button OUT), Turn ON the Scope by pressing ON/STBY button at the lower-left corner of the scope front-panel. After approximately 30 sec the standby screen will appear on the scope display. See Figure 3. © Bruce Mayer, PE • Chabot College • 282216578 • Page 1 7. Again review the CFG250 settings listed in Appendix 1. 8. Turn on the Signal Generator. This should produce a v(t) Scope Trace that looks Similar to that shown in Figure 4 . If the trace does NOT resemble Figure 4, then press the AUTOSET button on the scope one time. If this does not yield the desired trace then see the instructor. The AUTOSET button may be used at anytime to return to a “BaseLine” trace. 9. Examine the scope display. It shows a graph of voltage verses time [v(t) vs t] on a grid that is 8-Squres high by 10 squares wide. Notice along the bottom of the grid that scope displays SCALING information for the squares. Figure 5 The vertical scale in VOLTS shown on the scope display indicates a unit scale of 2V (2 volts per square or 2 VOLTS/DIV) The horizontal scale in SECONDS shown on the scope display indicates a unit scale of 500 μs (500 μs per square or 500x10-6 SEC/DIV) 10. Make the measurements and calculations required to complete Table I. Ensure that the Green LED1 next to CH 1 is illuminated. See Figure 6. This enables the vertical and horizontal controls for the Channel-1 scope trace. To make the measurements adjust the large VERTICAL-SCALE and HORIZONTALSCALE knobs and dials indicated by the arrows (→) in Figure 1 to obtain for ONE CYLCE on the scope trace the MAXIMUM Vertical Deflection (Squares Up & Down) Horizontal Deflection (Squares Side-to-Side) Move the trace to an advantageous measurement position using the small POSITION knob. The expanded and well-positioned trace should look similar to Figure 7 Measure Vpp by counting the number of vertical divisions between the bottom of the signal-trace and the top of the trace. On old scopes this was called the Vertical Deflection of the “Cathode Ray” (electron beam) that drew the trace Calculate Vpp by multiplying: Vpp = [no. vert. div]•[VOLTS/DIV] Measure the Signal period, T, by counting the number of horizontal divisions between one of: Adjacent peaks Adjacent troughs Adjacent zero-crossing points Calculate T by multiplying: T = [no. hori. div]•[SEC/DIV] Then the Frequency, f = 1/T 1 LED ≡ Light Emitting Diode © Bruce Mayer, PE • Chabot College • 282216578 • Page 2 Figure 1 • CFG250 Function (Signal) Generator Control Panel Figure 2 CFG250-TDS340 connection © Bruce Mayer, PE • Chabot College • 282216578 • Page 3 Figure 3 Scope Start-up Screen (CFG250 turned OFF) Figure 4 Successful Scope and Signal-Generator Set-Up © Bruce Mayer, PE • Chabot College • 282216578 • Page 4 Figure 5 Baseline scope trace showing vertical scale ( 2V) and horizontal scale (500μs) © Bruce Mayer, PE • Chabot College • 282216578 • Page 5 Figure 6 Active Channel LED (CH 1). Vertical/Horizontal Scaling and Position Knobs. © Bruce Mayer, PE • Chabot College • 282216578 • Page 6 Figure 7 Scope Trace Expaned and Centered using the Vertical/Horizontal Scaling and Position Knobs. © Bruce Mayer, PE • Chabot College • 282216578 • Page 7 Table I – Scope Measurements SG FREQUENCY Dial Position SG Amplitude Dial Position 1. 0.4 30% 2. 1.0 60% 3. 1.5 100% 4. 0.6 20% 5. 1.3 50% 6. 2.0 80% No. Time Base t/div 1-Cycle Horizontal Deflection Period, T Frequency Voltage Scale V/div Vpp Vertical Deflection Vpp Voltage NOTE: Adjust the HORIZONTAL-SCALE setting to obtain the MAXIMUM Horizontal Deflection (Squares Side-to-Side) allowed by the screen width while displaying at least one complete Period i.e; the measured horizontal distance should FILL THE SCREEN to maximum extent possible Adjust VERTICAL-SCALE setting to obtain the MAXIMUM Vertical Deflection (Squares Up & Down) allowed by the screen height while still displaying the positive and negative peaks i.e; the measured vertical distance should FILL THE SCREEN to maximum extent possible Part-2 Directions 1. Reset the FREQUENCY dial on the CFG250 to approximately 1.0. 2. Adjust the CFG250 AMPLITUDE dial to 0 and 100, and use the scope to make the SG characterization Measurements/Calculations needed to complete Table II. Table II – Function Generator Amplitude Characterizations © Bruce Mayer, PE • Chabot College • 282216578 • Page 8 SG Amplitude Dial Position Vpp Vertical Deflection Vpp Voltage 0% 100% Part-3 Directions 1. Adjust the FREQUENCY dial on the CFG250 to approximately 1.7. 2. Adjust the AMPLITUDE dial on the CFG250 as required by Table III, and use the scope to complete all but the last two columns of the Table A summary of the Amplitude Calculations VM = Vpp/2 VRMS = VM/2 Vavg = AVG(|Vsrc|) = 2VM/ = 0.6366VM 3. Now measure the RMS voltage of the SG. Remove the BNC-BNC cable from the SG output, and connect in its place a BNC-to-ClipLead Cable Connect the DMM to the Clip Leads Connect the COMMON lead to the Black ClipLead Connect the V/kΩ/S lead to the Red ClipLead Set DMM controls Set Measurement to V (green field) Set AC/DC button to the IN position to yield “TRUE RMS” values Read the RMS voltage on the DMM display and enter the value in Table III 4. Calculate the VRMS % between the Scope and the DMM as VRMS , DMM VRMS ,Scope % 100 VRMS , DMM VRMS , Scope VRMS 100 2 VRMS ,avg © Bruce Mayer, PE • Chabot College • 282216578 • Page 9 Table III – Average and RMS Amplitudes for Sinusoidal Signal No. Scope Vpp Nominal 1. 1V 2. 2.5 V 3. 5V 4. 8V 5. 12V 6. 17.5 Scope Vpp Measured VM (calc) Vavg (calc) VRMS (calc) DMM VRMS measured VRMS % (calc) Part-4 Directions (TIME PERMITTING) Reconnect the BNC cable to the scope. Recover the 1 kHz, 10 Vpp signal obtained in Part-1. Now Experiment with the Signal Generator and the scope. Try: Different RANGE (Hz) buttons; say 100 and 10k o Note that the TDS340 Scope is rated to 100 kHz, so it cannot reliably measure MHz signals Different Wave-Forms which include o “Square” wave → use the left button o “Saw-Tooth” wave → use the center button Return all Lab hardware to the As-Found Condition © Bruce Mayer, PE • Chabot College • 282216578 • Page 10 Run Notes/Comments Print Date/Time = 29-May-16/04:00 Appendix 1 – Scope Testing Initial Instrument Settings Equipment TEK CFG250 Signal (function) Generator o Settings Range (Hz) 1kHz Frequency Modulation Dial 1.0 Frequency (0-2 range) Function Sine wave Main output (20Vpp) AMPLITUDE = Midway Between MIN and MAX (0-100% range) VOLTS OUT = 0-20 Vpp Settings NOT used DC OFFSET (set to middle) DUTY (set to middle) INVERT (button OUT) SWEEP (button OUT) SWEEP RATE (set to middle) SWEEP WIDTH (set to middle) Appendix 2 – BNC Connector Definition BNC (Bayonet Neill Concelman) Invented by and named after Amphenol Engineer Carl Concelman and Bell Labs Engineer Paul Neill and was developed in the late 1940's. A coaxial connector with bayonet coupling mechanism. This connector is available in 50 Ohm and 75 Ohm versions. This connector has a frequency range of DC (0 HZ) through 4 GHz (50 Ohm version) and DC (0 HZ) through 1 GHz (75 Ohm version). The BNC connector is available in standard and reverse polarity configurations. © Bruce Mayer, PE • Chabot College • 282216578 • Page 11