Chabot College Fall 2008 – Powertrain and Vehicle Performance

advertisement

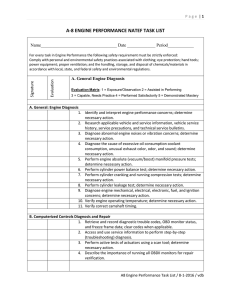

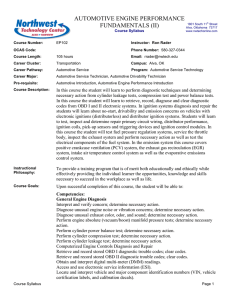

Chabot College Fall 2008 Course Outline for Automotive Technology 71 Powertrain and Vehicle Performance Catalog Description: 71 – Powertrain and Vehicle Performance May be repeated three times 8 Units Continued study of electrical/electronic and fuel control systems, including engine management systems, emission control systems, emissions testing, drivability and vehicle performance diagnosis and repair. Prerequisites: Automotive Technology 60 and 61. 5 hours lecture, 11 hours laboratory. [Typical contact hours: lecture 87.5; laboratory 192.5] Prerequisite Skills: Before entering the course the student should be able to: 1. identify and interpret electrical/electronic system concern, and determine necessary action; 2. diagnose electrical/electronic integrity for series, parallel and series-parallel circuits using principles of electricity (Ohm’s Law); 3. demonstrate the proper use of a digital multimeter (DMM),test lights and fused jumper wires during diagnosis of electrical circuit problems; 4. measure and diagnose the cause(s) of excessive key-off battery drain (parasitic draw); 5. inspect and test fusible links, circuit breakers, and fuses, repair wiring harnesses and connectors, and perform solder repair of electrical wiring; 6. perform battery state-of-charge test, capacity test, and confirm proper battery capacity for vehicle application; 7. perform battery service, perform slow/fast battery charge, inspect and clean battery cables, connectors, clamps, and hold-downs, repair or replace as needed; 8. start a vehicle using jumper cables and a battery or auxiliary power supply; 9. perform starter current draw tests, generator (alternator) output tests, circuit voltage drop tests; 10. inspect and test starter relays and solenoids; 11. remove and install starters and alternators; 12. inspect, adjust, or replace generator (alternator) drive belts, pulleys, and tensioners; check pulley and belt alignment; 13. diagnose the cause of brighter than normal, intermittent, dim, or no light operation in lighting systems; 14. inspect, replace, and aim headlights and bulbs; 15. inspect and diagnose incorrect turn signal or hazard light operation; 16. inspect engine assembly for fuel, oil, coolant, and other leaks; 17. diagnose abnormal exhaust color, odor, and sound; 18. perform engine vacuum analysis; 19. prepare 4 or 5 gas analyzer; obtain exhaust readings, interpret readings and determine necessary action; 20. retrieve and record stored OBD I diagnostic trouble codes; clear codes; 21. inspect and test mechanical and electrical fuel pumps and pump control systems for pressure, regulation and volume, and perform necessary action; 22. replace fuel filters; 23. check and adjust idle speed and fuel mixture; 24. inspect the integrity of the exhaust manifold, exhaust pipes, muffler(s), catalytic converter(s), resonator(s), tail pipe(s), and heat shield(s); perform necessary action; Chabot College Course Outline for Automotive Technology 71, Page 2 Fall 2008 25. inspect throttle body, air induction system, intake manifold and gaskets for vacuum leaks and/or unmetered air; 26. diagnose emissions, and driveability problems resulting from malfunctions in the positive crankcase ventilation (PCV) system. Expected Outcomes for Students: Upon completion of the course the student should be able to: 1. inspect and test ignition primary and secondary circuit wiring and components 2. inspect, test and service distributor; 3. inspect and test ignition coil(s), check and adjust ignition system timing and timing advance/retard (where applicable); 4. inspect and test gauges and gauge sending units for cause of intermittent, high, low, or no gauge readings; 5. inspect and test sensors, connectors, and wires of electronic instrument circuits; 6. diagnose incorrect wiper/washer operation, and perform necessary action; 7. diagnose incorrect operation of motor-driven accessory circuits, and determine necessary action; 8. diagnose supplemental restraint system (SRS) concerns; determine necessary action; 9. diagnose body electronic system circuits using a scan tool; 10. obtain and interpret scan tool data, retrieve and record stored OBD diagnostic trouble codes; 11. diagnose the causes of emissions or drivability concerns resulting from malfunctions in the computerized engine control system with or without diagnostic trouble codes; 12. inspect and test computerized engine control system sensors, powertrain control module (PCM), actuators, and circuits using a graphing multimeter (GMM)/digital storage oscilloscope (DSO), and perform necessary action; 13. access and use service information to perform step-by-step diagnosis; 14. diagnose ignition system related problems such as no-starting, hard starting, engine misfire, poor drivability, spark knock, power loss, poor mileage, and emissions concerns on vehicles with electronic ignition systems, and determine necessary action; 15. check and adjust ignition system timing and timing advance/retard (where applicable); 16. inspect and test ignition system pick-up sensor or triggering devices, and perform necessary action; 17. diagnose hot or cold no-starting, hard starting, poor drivability, incorrect idle speed, poor idle, flooding, hesitation, surging, engine misfire, power loss, stalling, poor mileage, dieseling, and emissions problems on vehicles with carburetor and fuel injection systems; 18. perform exhaust system back-pressure test, and determine necessary action; 19. diagnose malfunctions of emission control systems causing vehicle performance problems, and determine necessary action; 20. adjust valves on engines with mechanical or hydraulic lifters; 21. diagnose and verify correct camshaft timing, and determine necessary action; 22. use vehicle dynamometer to perform emission testing, and engine performance/drivability issues. Chabot College Course Outline for Automotive Technology 71, Page 3 Fall 2008 Course Content: 1. Fuel Injection Systems a. fuel delivery and storage b. fuel injectors c. pressure controls d. fuel delivery control 2. Emission Control Systems a. positive crankcase ventilation b. air injection systems c. air intake systems d. exhaust gas recirculation e. fuel evaporation f. catalytic converters 3. Electronic Ignition Systems a. distributor type b. distributor-less type c. coil-on-plug 4. Computer Control Systems 5. Electrical/Electronic Body Control Systems a. windshield wipers b. electric windows c. door locks d. communication bus system e. lighting systems f. supplemental restraint systems 6. Automotive diagnostic equipment a. oscilloscopes b. digital multimeters c. diagnostic analyzers d. dynamometer e. pressure and vacuum gauges f. exhaust gas analyzers g. specialized test equipment Methods of Presentation: 1. 2. 3. 4. 5. Lecture/demonstrations (use of multimedia) Laboratory Laboratory work sheets Guest speakers Field trips Chabot College Course Outline for Automotive Technology 71, Page 4 Fall 2008 Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Read chapter on Electronic Fuel Injection and Operation and be prepared to discuss. b. Complete worksheet utilizing information from lecture. c. Demonstrate use of fuel pressure testing equipment. d. Demonstrate use of the exhaust emission analyzers. 2. Methods of Evaluating Student Progress a. Class participation b. Performance in the laboratory projects c. Laboratory work sheets d. Home work e. Quizzes f. Tests on chapter sections. g. Final examination (written and/or lab practical) Textbook(s) (Typical): Automotive Engine Performance, James D. Halderman, Prentice Hall, 2003 Diagnosis and Troubleshooting of Automotive Electrical, Electronic, and Computer Systems, Third Edition, James D. Halderman, Prentice Hall, 2001 Special Student Materials: 1. 2. Safety glasses Shop/safety clothing SAS Sept 2007, 31Oct07 ATEC 71 course outline.doc