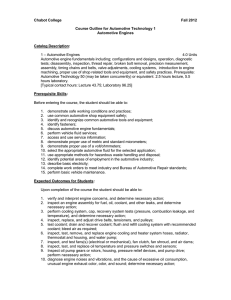

Chabot College Fall 2010 Course Outline for Automotive Technology 63B

advertisement

Chabot College Fall 2010 Course Outline for Automotive Technology 63B ENGINES, MACHINING AND ASSEMBLY PROCESSES Catalog Description: 63B - Engines, Machining and Assembly Processes (May be repeated three times) 3 units Continuation of Automotive Technology 63A with emphasis on cylinder head assembly, camshaft design and servicing, inspection, machining operations, and reconditioning of engine blocks including final assembly and installation of engines. Prerequisite: Automotive Technology 63A (completed with a grade of C or higher), or equivalent. 1.5 hours lecture, 5 hours laboratory. [Typical contact hours: lecture 26.25, laboratory 87.5] Prerequisite Skills: Before entering the course the student should be able to: 1. verify and interpret engine concerns, and determine necessary action; 2. inspect an engine assembly for fuel, oil, coolant, and other leaks, and determine necessary action; 3. perform cooling system, cap, recovery system tests (pressure, combustion leakage, and temperature), and determine necessary action; 4. inspect, replace, and adjust drive belts, tensioners, and pulleys; 5. test coolant; drain and recover coolant; flush and refill cooling system with recommended coolant; bleed air as required; 6. inspect, test, remove, and replace engine cooling and heater system hoses, radiator, thermostat and housing, and water pump; 7. inspect, and test fans(s) (electrical or mechanical), fan clutch, fan shroud, and air dams; 8. inspect, test, and replace oil temperature and pressure switches and sensors; 9. Inspect oil pump gears or rotors, housing, pressure relief devices, and pump drive; perform necessary action; 10. perform cylinder power balance tests, and determine necessary action; 11. diagnose engine noises and vibrations, and the cause of excessive oil consumption, unusual engine exhaust color, odor, and sound; determine necessary action. 12. visually inspect cylinder head(s) for cracks, check gasket surface areas for warpage and leakage; 13. install cylinder heads and gaskets, and tighten according to manufacturers specifications and procedures; 14. inspect and test valve springs for squareness, pressure, free-height comparison, valve spring retainers, locks, and valve grooves and replace as needed; 15. inspect valve guides for wear, check valve guide height, and stem-to-guide clearance, recondition or replace as needed; 16. resurface valves, valve seats and perform necessary action; 17. check valve spring assembled height and valve stem height; service valve and spring assemblies as needed; 18. inspect pushrods, rocker arms, rocker arm pivots and shafts for wear, bending, cracks, looseness, and blocked oil passages (orifices), and perform necessary action; 19. adjust valves (mechanical or hydraulic lifters); 20. inspect and replace timing belt(s), overhead cam drive sprockets, and tensioners, check belt tension, and adjust as necessary; 21. verify camshaft(s) timing according to manufacturer’s specifications and procedures; 22. inspect camshaft drives (including gear wear and backlash, sprocket and chain wear); replace as necessary. Chabot College Course Outline for 63B, Page 2 Fall 2010 Expected Outcomes for Students: Upon completion of the course the student should be able to: 1. inspect camshaft for runout, journal wear and lobe wear; 2. establish camshaft(s) timing and cam sensor indexing according to manufacturer’s specifications and procedures; 3. disassemble engine block; clean and prepare components for inspection and reassembly; 4. inspect engine block for visible cracks, passage condition, core and gallery plug condition, surface warpage, and determine necessary action; 5. inspect and measure cylinder walls for damage/wear, deglaze and determine necessary action; 6. Inspect crankshaft for end play, straightness, journal damage, keyway damage, thrust flange and sealing surface condition, and visual surface cracks; check oil passage condition; measure journal wear; check crankshaft sensor reluctor ring (where applicable); determine necessary action; 7. Inspect and measure main and connecting rod bearings for damage, clearance, and end play; determine necessary action ; 8. replace camshaft, main and connecting rod bearings using manufacturer’s recommended procedures; 9. inspect, measure, service pistons and pins, and install piston rings; 10. assemble the engine using gaskets, seals, and formed-in-place (tube-applied) sealants, thread sealers, etc. according to manufacturer’s specifications; 11. reassemble engine components using correct gaskets and sealants; 12. prime engine lubrication system; 13. remove and reinstall engine in a late model front-wheel drive vehicle (OBDI or newer); reconnect all attaching components and restore the vehicle to running condition. Course Content (Lecture): 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Automotive safety and shop practice Proper care and manipulation of basic hand tools Complete engine removal and installation procedures Engine valve train, cylinder head assembly and installation procedures Engine block fundamentals, inspection, construction and components Engine block diagnosis, inspection, repair and reconditioning Piston, rings, and connecting rod diagnosis and servicing Crankshafts, testing, inspection and servicing Camshafts and valve train components, testing, inspection and servicing Engine reassembly, gaskets, sealants, installation techniques and procedures Engine fluid leaks, diagnosis, inspection and servicing Hazardous waste handling Course Content (Laboratory): Each of the lecture content items is accompanied by a required NATEF (National Automotive Technical Education Foundation) lab “task sheet” with required levels of exposure (general knowledge, demonstration, basic skill level, advanced skill level. Examples include: 1. Demonstrated use of precision measuring tools 2. Disassembly, inspection, and reassembly of an engine 3. Repair of engine valve train Chabot College Course Outline for 63B, Page 3 Fall 2010 Methods of Presentation: 1. 2. 3. 4. Lecture/discussion Laboratory Guest speakers Field trips Assignments and Methods of Evaluating Student Progress: 1. Typical Assignments a. Read chapter titled “Engine Block Construction and Service” b. Measure cylinder bore, taper and out-of-roundness following directions listed and the class lecture/discussion 2. Methods of Evaluating Student Progress a. Class participation b. Performance of laboratory task lists and projects c. Homework assignments d. Quizzes e. Midterm examination f. Final examination Textbook(s) (Typical): Intro to Engines and Machining, Author-Gilles, Publisher-Prentice Hall, 2007 Special Student Materials: 1. Safety glasses 2. Shop/safety clothing JGB Atec 63B course outline Revised: Sept2009