ISPE NJ Chapter Tour Demo of Aseptic Filling Line with

advertisement

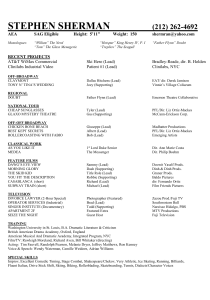

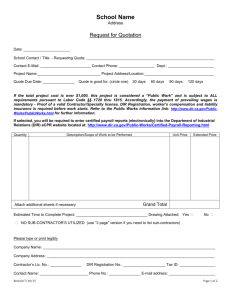

ISPE NJ Chapter Tour Demo of Aseptic Filling Line Tour-Demo with Validation Workshop Dragutin Stoicovici Director of Quality Assurance February 16, 2011 Dragutin Stoicovici, Dir. of QA www.cozzoli.com Technology h l Review i • Pharmaceutical, Cosmetics, Biotech Products • Aseptic Packaging • Clean Room • cGMP Dragutin Stoicovici, Dir. of QA Requirements i • • • • Dragutin Stoicovici, Dir. of QA Equipment Requirements FDA/USDA Expectations p cGMP Requirements Validation Terminology i l • Endotoxin – a toxin produced within a microorganism • Pyrogen P – a substance b that h produces d ffever. Endotoxins are pyrogens. • Log L Reduction R d ti – reduction d ti off Endotoxin E d t i or Biological indicator (1Log=10 times less, 2Log=100 2Log 100, 3Log=1000 3Log 1000…)) Dragutin Stoicovici, Dir. of QA Terminology i l • A Aseptic i Core C – area requires i special i l gowning • Washroom W h – vials i l washed h d andd delivered for sterilization (oven or tunnel) • Fill Room – vials are filled with drug product and then closed Dragutin Stoicovici, Dir. of QA Aseptic i Fill ill Line i • • • • • Dragutin Stoicovici, Dir. of QA Vial Washer – class 10000/100000 Sterilizer, Depyrogenation py g Tunnel Filler – class 100 Closing: Plugger, Plugger Capper, Capper Stoppering Crimping – class 10000 Containers i • • • • • • Dragutin Stoicovici, Dir. of QA vials bottles ampules syringes IV type bags Special… Product d • Liquid – flammability, density, viscosity, suspension… • Powder – humidity, static charge, pparticle shape p and size • Tablets Dragutin Stoicovici, Dir. of QA Washing hi Equipment i Vials, Bottles, Ampules, Stoppers • Batch • Automatic Dragutin Stoicovici, Dir. of QA Filling illi Equipment i Liquid, Powder • Semiautomatic • Mid Range – Intermittent • High Speed – Continuous • Inline • Rotary Dragutin Stoicovici, Dir. of QA Liquid i id Filling illi Methods h d • • • • • Dragutin Stoicovici, Dir. of QA Piston Pump Diaphragm Pumps Peristaltic Pump Mi Micro Fill Fillers (IVEK) Time Pressure Closing l i Equipment i Ampules, Stoppering, Plugging, Capping • Semiautomatic • Intermittent • Continuous C i Dragutin Stoicovici, Dir. of QA Monoblock bl k Equipment i Ampules, Stoppering, Plugging, Capping • Fill, Seal Ampules • Fill, Plug, Cap • Fill, Stopper Dragutin Stoicovici, Dir. of QA Ancillary ill Equipment i Ampules, Stoppering, Plugging, Capping • Unscramblers • Conveyors • Bottle Trayers Dragutin Stoicovici, Dir. of QA Before you start… Ri k Based Risk B d Approach A h Dragutin Stoicovici, Dir. of QA h // http://www.youtube.com/watch?v=IFFvATEW6dM b / h? IFF ATEW6dM VIDEO Dragutin Stoicovici, Dir. of QA Vhat is Validation? “Establishing “E bli hi documented d d evidence id which provides a high degree of assurance that a specific process will consistentlyy pproduce a product p meetingg its pre-determined specifications and quality attributes. attributes ” Dragutin Stoicovici, Dir. of QA Require Documentation: -Customer Specification (May include SOP’s) -Manufacturer’s Proposal -Purchase Purchase OrderOrder do not need the dollar amounts -Order Acknowledgement -Customer component drawings -Electrical Schematics/Drawings -All All drawings provided for the equipment. equipment An index of drawings only, only will be acceptable. -Cut Sheets for components utilized in the manufacturer of the equipment -Material Material Certification for product contact and exposed parts. parts Certification must include which parts were manufactured from the materials. -Passivation reports (where Passivation is required) -Electropolish reports (when electropolish is required) -Bill of Material, listing component manufacturer, model no, type, etc. -Operator interface screens -Ladder Logic (where PLC is utilized) Dragutin Stoicovici, Dir. of QA Title page Equipment Location Protocol Dragutin Stoicovici, Dir. of QA Approvals Author Blank Protocol Approval Fi l Protocol Final P t l Approval A l Dragutin Stoicovici, Dir. of QA Each Section Purpose Scope Dragutin Stoicovici, Dir. of QA Certification …to the best of executor s knowledge executor’s knowledge… If the executor is not qualified in a specific area then qualified help shall h ll be b used. d Dragutin Stoicovici, Dir. of QA System description Introduction Process Definition Dragutin Stoicovici, Dir. of QA System description …more… Process Definition Dragutin Stoicovici, Dir. of QA Instructions to be followed when executing the protocol and … Dragutin Stoicovici, Dir. of QA Responsibilities assigned Dragutin Stoicovici, Dir. of QA Acceptance Criteria G id d by Guided b the th Instructions I t ti and using the Method, the acceptance needs to be confirmed. Any deviation will be noted and a course of action initiated. Dragutin Stoicovici, Dir. of QA Check List This is the script for executing the protocol. Each item will be accepted or rejected, if there are multiple methods of verifying, then specify method, and always initial and date. Also at the bottom of each page note any comments and the persons that completed and verified sign and date. date Dragutin Stoicovici, Dir. of QA IQ Check List -Equipment and Instrument Check list -Documentation Documentation -Drawings, Schematics and Component Identification -Supporting Supporting Utilities Dragutin Stoicovici, Dir. of QA OQ Check List -Instrument Calibration -Operator Interface -Manual and Automatic Controls -PLC PLC Logic and Controls -Alarms -Fill Weight Verification (or other critical parameters) -Capping Verification Dragutin Stoicovici, Dir. of QA PQ Check List -Reference (Any relevant SOPs) -Process Instruments -Media Fills -Cap Seal Integrity -Capping Application (torque) Dragutin Stoicovici, Dir. of QA PQ Check List As IQ is very generic in relation to the process, the OQ becomes more specific involving specific groups of people (operators) and SOPs, and the PQ is totally dependant of the specific process. Dragutin Stoicovici, Dir. of QA Summary of Results The acceptance criteria of every section will be listed here together with the result. here, result Dragutin Stoicovici, Dir. of QA Exception Report All Exceptions are captured in this section. This is done every time an acceptance criteria can not be fulfilled. Dragutin Stoicovici, Dir. of QA Exception Report A protocol execution is successful only after each and every one of the exceptions have been corrected. Dragutin Stoicovici, Dir. of QA The End … Dragutin Stoicovici, Dir. of QA …well, this is just the beginning. Once the equipment has been successfully validate, all changes shall be made under change control. control There also is a regular revalidation cycle, every 6 month (or a year) as dictated by your SOP. Dragutin Stoicovici, Dir. of QA The end of the validation effort will come only when the equipment has reached it’s end of life and it’s decomission has been completed. Dragutin Stoicovici, Dir. of QA References: 21 CFR Parts 210 & 211 21 CFR Part 11 GAMP cG cGMP USP 24 <1211> - Sterility USP 24 <85> - Biological Test, Bacterial Endotoxin Tests www . fda . gov www . ispe p . orgg Dragutin Stoicovici, Dir. of QA Thank you y Dragutin Stoicovici, Dir. of QA