Food Cycling Within New Haven, Connecticut: Creating Opportunities for Economic,... and Environmental Progress Through Industrial Symbiosis

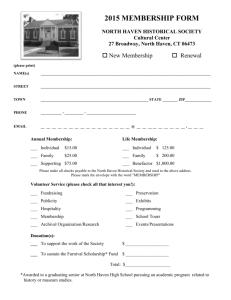

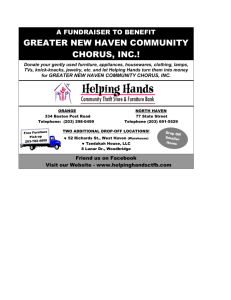

advertisement