NCHRP Report 810: Consideration of Preservation in Pavement Design and Analysis Procedures

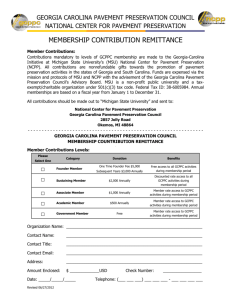

advertisement